Wire feeding pen for TIG welding of argon arc welding

A technology for argon arc welding and welding wire, which is applied in the field of wire feeder for argon arc welding TIG welding, can solve the problems of difficulty in ensuring welding quality and appearance, inconvenient operation, and difficulty in accurate, uniform and stable wire feeding. The effect of wire stability, wire feeding angle control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the protection scope of the present invention cannot be limited by this. The purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

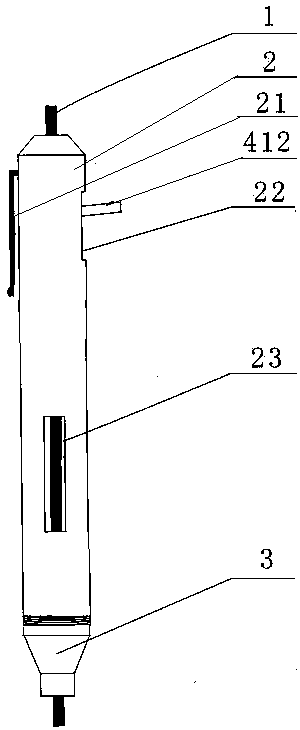

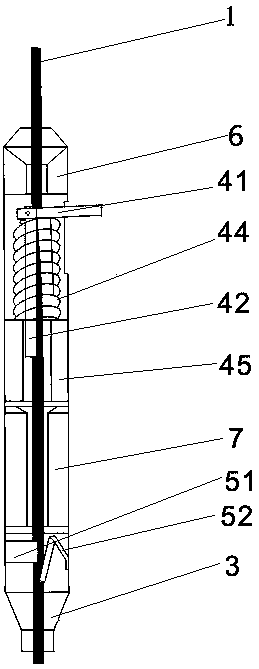

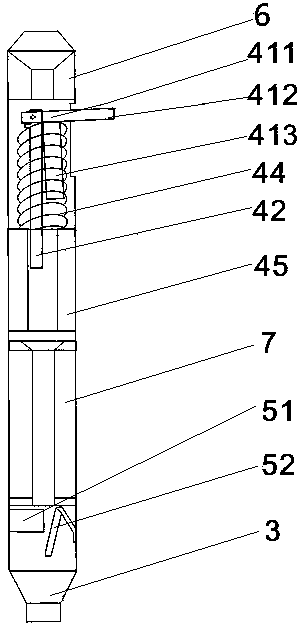

[0037] combined with Figure 1-10 A wire feeder pen for argon arc welding TIG welding, comprising a wire feeder body 2, a porcelain nozzle 3, a first wire feeder 6, a pressing wire feeder mechanism, a damping check device and a second wire feeder 7.

[0038] The wire feed pen body 2 is a hollow rod-shaped structure, and the upper end is provided with a welding wire 1 installation hole; the outer edge of the wire feed pen body 2 rod-shaped structure is provided with a long strip-shaped gap 22 along the length direction, relative to the gap 22- The outer edge of the side is provided with a pen clip 21; the lower end of the wire feed pen body 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com