A surface treatment process for stainless steel flux-cored wire

A flux-cored wire and surface treatment technology, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as pores on the surface of the weld bead, and achieve the effect of smooth wire feeding, healthy wire, and clean wire surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

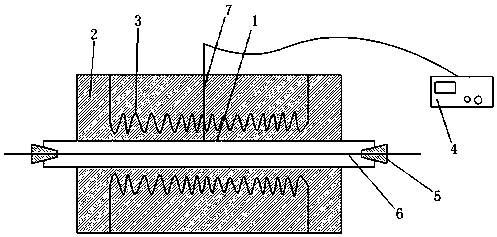

Image

Examples

Embodiment 1

[0022] A surface treatment process for stainless steel flux-cored welding wire. First, the stainless steel flux-cored welding wire is heated instantaneously to eliminate oil stains and wire drawing powder on the surface of the welding wire, and then the surface is coated with existing special lubricating oil for smooth wire feeding;

[0023] The instantaneous heating refers to raising the temperature of the stainless steel flux-cored wire to 180° C. within 1 second in an aerobic environment, and then naturally cooling to normal temperature;

[0024] The coating of special lubricating oil on the surface of the welding wire refers to the use of electrostatic oiling method to coat the surface of the welding wire with a layer of molecular-level thick oil film, and the coating amount of the special lubricating oil is 1g of special lubricating oil per 100kg of welding wire .

Embodiment 2

[0026] A surface treatment process for stainless steel flux-cored welding wire. First, the stainless steel flux-cored welding wire is heated instantaneously to eliminate oil stains and wire drawing powder on the surface of the welding wire, and then the surface is coated with existing special lubricating oil for smooth wire feeding;

[0027] The instantaneous heating refers to raising the temperature of the stainless steel flux-cored wire to 240° C. within 2 seconds in an aerobic environment, and then cooling it naturally to room temperature;

[0028] The coating of special lubricating oil on the surface of the welding wire means that the surface of the welding wire is coated with a layer of molecular-level thick oil film by means of electrostatic oiling, and the coating amount of the special lubricating oil is 4g of special lubricating oil per 100kg of welding wire. .

Embodiment 3

[0030] A surface treatment process for stainless steel flux-cored welding wire. First, the stainless steel flux-cored welding wire is heated instantaneously to eliminate oil stains and wire drawing powder on the surface of the welding wire, and then the surface is coated with existing special lubricating oil for smooth wire feeding;

[0031] The instantaneous heating refers to raising the temperature of the stainless steel flux-cored welding wire to 180° C. within 2 seconds in an aerobic environment, and then naturally cooling to normal temperature;

[0032] The coating of special lubricating oil on the surface of the welding wire means that the surface of the welding wire is coated with a layer of molecular-level thick oil film by means of electrostatic oiling, and the coating amount of the special lubricating oil is 4g of special lubricating oil per 100kg of welding wire. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com