Welding wire reel frame

A welding wire reel and turntable technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of wire sticking, etc., and achieve the effect of smooth wire feeding, no sticking, and flexible rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

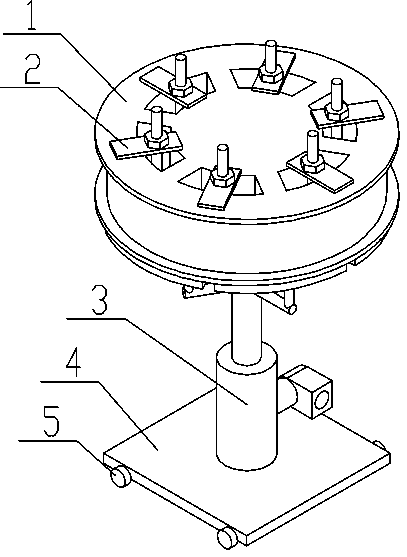

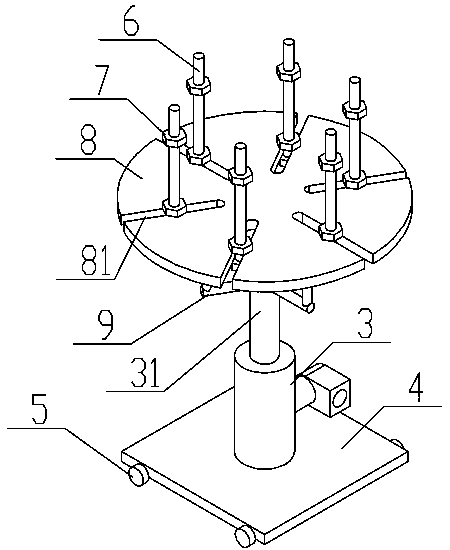

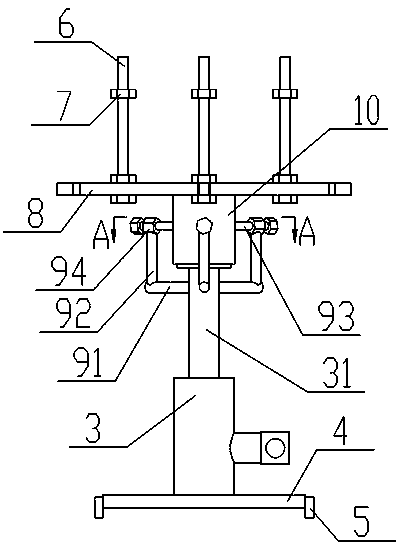

[0017] see Figure 1-5 , present embodiment comprises base 4, and jack 3 is housed on base 4, and the top of piston rod 31 of jack 3 is equipped with sleeve 10 through slewing bearing 11, and the top of sleeve 10 is fixedly connected with a turntable 8, and on turntable 8 radially uniform A plurality of elongated through holes 81 are provided, each elongated through hole 81 is equipped with a support column 6 through a bolt, each support column 6 is set with a pressing plate 2, and a compression nut 7 is installed above the pressing plate 2.

[0018] The bottom of the base 4 in this embodiment is provided with rollers 5 .

[0019] The jack 3 described in this embodiment is a screw jack, and the QL3.2 screw jack produced by Shanghai Qize Hoisting Machinery Co., Ltd. is selected for use.

[0020] The piston rod 31 of the jack 3 described in this embodiment is evenly equipped with at least three brackets 9 (specifically three), and the upper end of the bracket 9 is close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com