Porous platinum fuel cell catalyst and preparation method thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced activity, increased volume, weight and cost of fuel cell stacks, achieve high platinum utilization, prevent oxidation, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

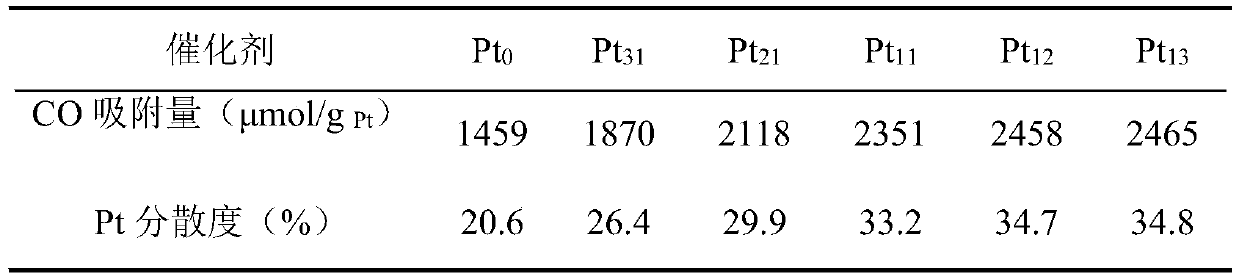

Embodiment 1

[0024] This embodiment discloses a method for preparing a porous platinum fuel cell catalyst, comprising the following steps:

[0025] Step (1) Dissolve chloroplatinic acid in water, the molar concentration of chloroplatinic acid is 12mmol / L, add polyvinylpyrrolidone, the ratio of the molar weight of polyvinylpyrrolidone to platinum molar weight is 10:1, that is, polyvinylpyrrolidone and The molar ratio of the amount of platinum metal is 10:1. Stir at 800 rpm for 60 minutes at room temperature to obtain a platinum metal salt aqueous solution;

[0026] Step (2) Add 2 mol / L sodium borohydride aqueous solution to the platinum metal salt aqueous solution system in step (1) while bubbling nitrogen gas, and stir at 800 rpm for 30 minutes at normal temperature; wherein, the sodium borohydride aqueous solution is added to the platinum metal salt aqueous solution After the system, the molar concentration of sodium borohydride in the solution system is 0.33mol / L;

[0027] Step (3) Con...

Embodiment 2

[0032] This embodiment discloses a method for preparing a porous platinum fuel cell catalyst, comprising the following steps:

[0033] Step (1) chloroplatinic acid and nickel nitrate hexahydrate are dissolved in water, wherein, the molar concentration of chloroplatinic acid is 3mmol / L, and the molar concentration of nickel nitrate hexahydrate is 9mmol / L; Add polyvinylpyrrolidone, polyvinylpyrrolidone The ratio of the molar weight of polyvinylpyrrolidone to the total molar weight of platinum and nickel is 10:1, that is, the molar ratio of polyvinylpyrrolidone to the total metal weight of platinum and nickel is 10:1. Stir at 800 rpm for 60 minutes at room temperature to obtain a platinum salt-nickel metal salt mixed aqueous solution system;

[0034] Step (2) Add 2mol / L sodium borohydride aqueous solution to the platinum salt-nickel metal salt mixed aqueous solution system of step (1) and blow nitrogen into it while stirring at a speed of 800 rpm for 30 min at normal temperature;...

Embodiment 3

[0039] This embodiment discloses a method for preparing a porous platinum fuel cell catalyst, comprising the following steps:

[0040] Step (1) chloroplatinic acid and nickel nitrate hexahydrate are dissolved in water, wherein, the molar concentration of chloroplatinic acid is 4mmol / L, and the molar concentration of nickel nitrate hexahydrate is 8mmol / L; Add polyvinylpyrrolidone, polyvinylpyrrolidone The ratio of the molar weight of polyvinylpyrrolidone to the total molar weight of platinum and nickel is 10:1, that is, the molar ratio of polyvinylpyrrolidone to the total metal weight of platinum and nickel is 10:1. Stir at 800 rpm for 60 minutes at room temperature to obtain a platinum salt-nickel metal salt mixed aqueous solution system;

[0041] Step (2) Add 2mol / L sodium borohydride aqueous solution to the platinum salt-nickel metal salt mixed aqueous solution system of step (1) and blow nitrogen into it while stirring at a speed of 800 rpm for 30 min at normal temperature;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com