Ion implanter cleaning method

An ion implanter and ion implantation technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as difficulty in meeting cleaning requirements, and achieve the effect of avoiding residue and accelerating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

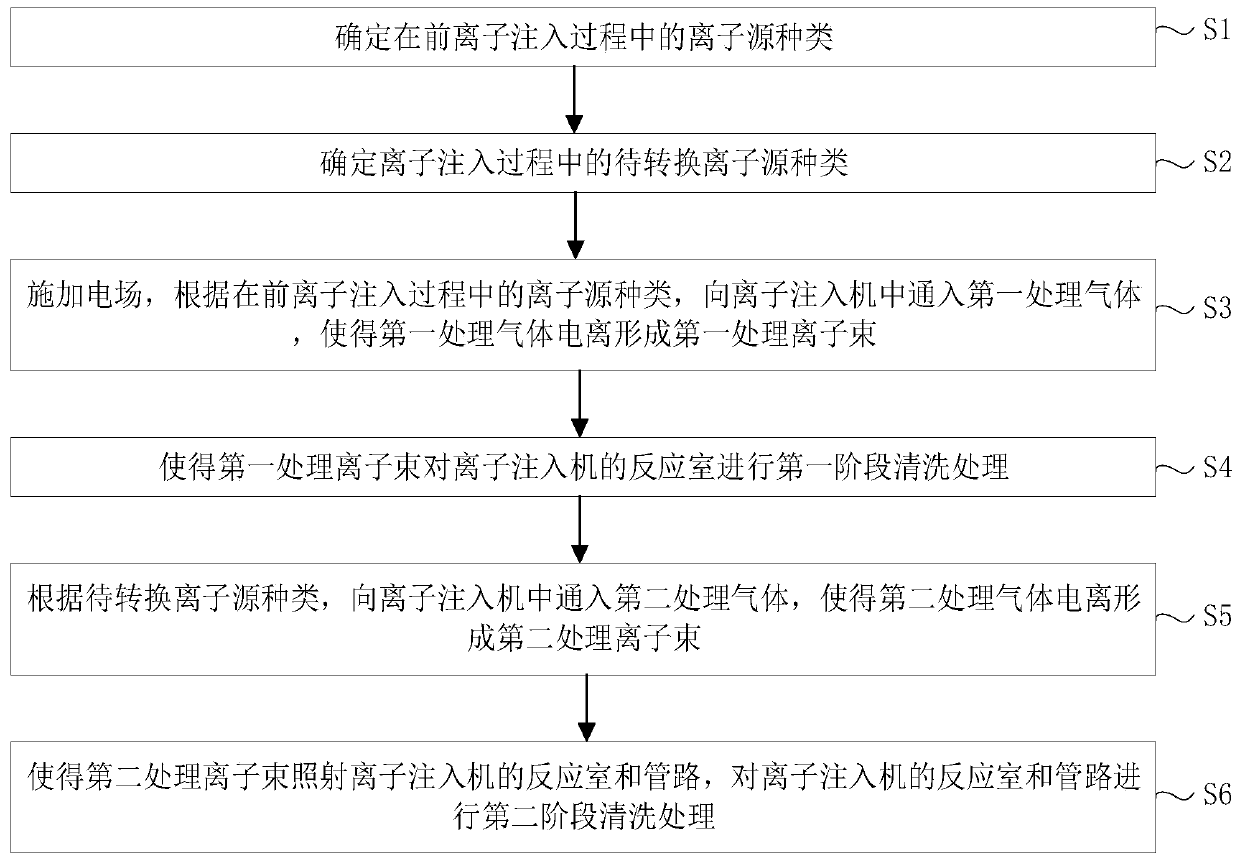

Method used

Image

Examples

Embodiment 1

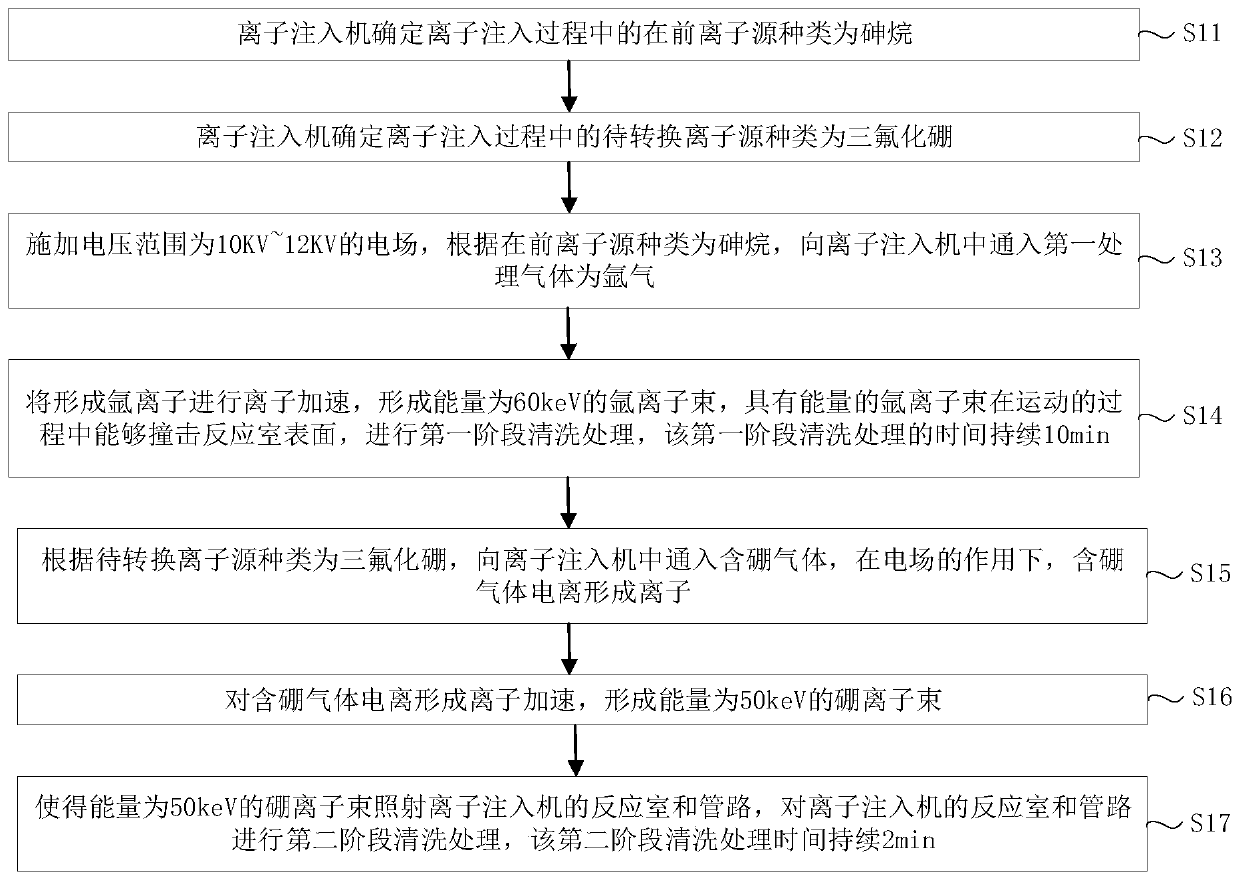

[0055] This embodiment provides a cleaning method for an ion implanter, referring to figure 2 , taking the former ion source as arsine and the ion source to be converted as boron trifluoride as an example.

[0056] S11: the ion implanter determines that the type of the previous ion source in the ion implantation process is arsine (AsH3);

[0057] S12: The ion implanter determines that the ion source to be converted during the ion implantation process is boron trifluoride (BF3);

[0058] S13: Apply an electric field with a voltage range of 10KV to 12KV. According to the type of the previous ion source is arsenic, the first processing gas introduced into the ion implanter is argon gas. Since argon gas is an inert gas, it is not easy to interact with other objects. reaction, so that argon gas can be used to ionize argon ions under the action of an electric field;

[0059] S14: Accelerate the formed argon ions to form an argon ion beam with an energy of 60keV. The argon ion bea...

Embodiment 2

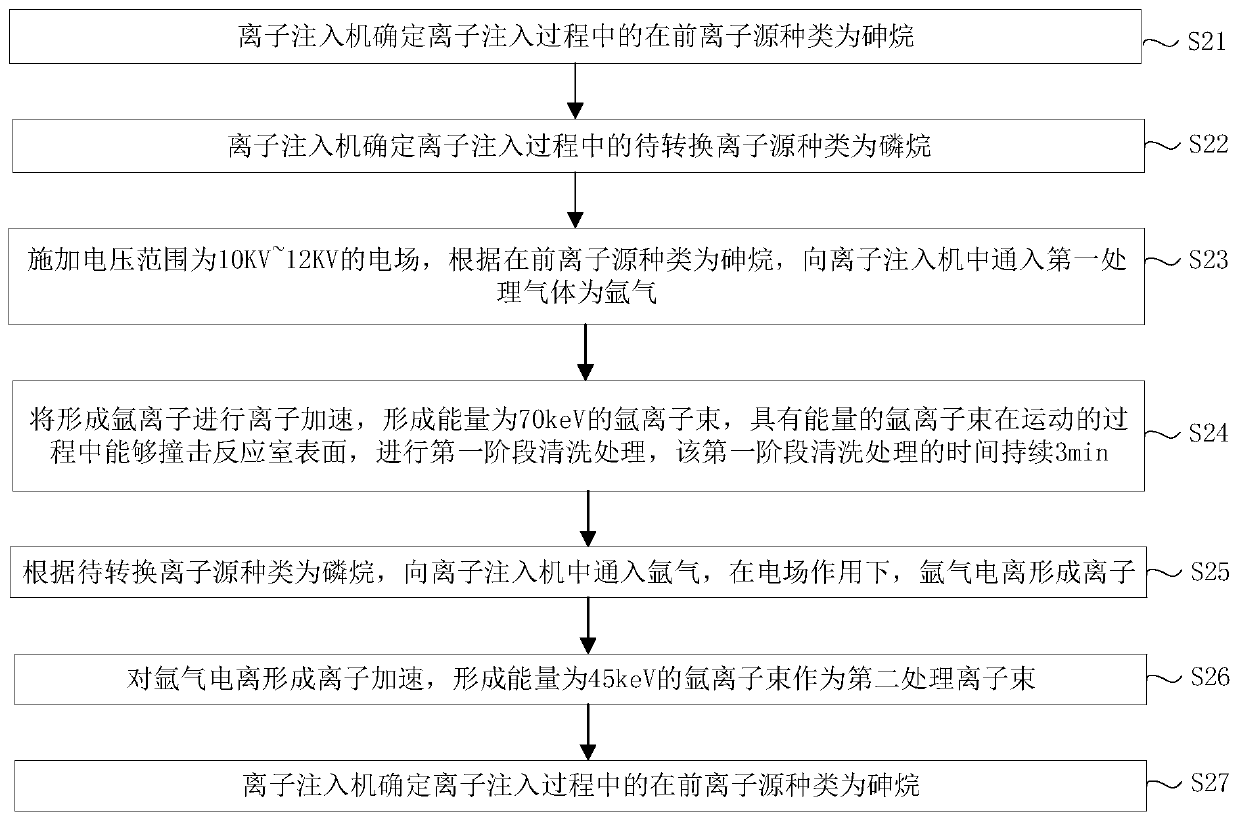

[0065] This embodiment provides a cleaning method for an ion implanter, referring to image 3 , taking the former ion source as arsine and the ion source to be converted as phosphine as an example.

[0066] S21: the ion implanter determines that the type of the previous ion source in the ion implantation process is arsine (AsH3);

[0067] S22: The ion implanter determines that the type of ion source to be converted during the ion implantation process is phosphine (PH3);

[0068] S23: Apply an electric field with a voltage range of 10KV to 12KV. According to the type of the previous ion source is arsine, the first processing gas is introduced into the ion implanter as argon gas. Since argon gas is an inert gas, it is not easy to interact with other objects. reaction, so that argon gas can be used to ionize argon ions under the action of an electric field;

[0069] S24: Accelerate the formed argon ions to form an argon ion beam with an energy of 70keV. The argon ion beam with ...

Embodiment 3

[0075] This embodiment provides a cleaning method for an ion implanter, referring to Figure 4 , taking the previous ion source as arsine and the ion source to be converted as germanium tetrafluoride as an example.

[0076] S31: the ion implanter determines that the type of the previous ion source in the ion implantation process is arsine (AsH3);

[0077] S32: The ion implanter determines that the type of ion source to be converted during the ion implantation process is germanium tetrafluoride (GeF4);

[0078] S33: Apply an electric field with a voltage range of 10KV to 12KV. According to the type of the previous ion source is arsine, and the first processing gas is argon into the ion implanter. Since argon is an inert gas, it is not easy to interact with other objects. reaction, so that argon gas can be used to ionize argon ions under the action of an electric field;

[0079] S34: Accelerate the formed argon ions to form an argon ion beam with an energy of 80keV. The argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com