Anti-scratch cleaning device for antiskid hub bolt

A technology of cleaning device and anti-slip wheel, which is applied in the direction of bolts, cleaning methods using liquids, nuts, etc., can solve the problems of mutual scratching, knurled thread damage, and damage to the cleaning device, so as to prevent thread and knurling damage, and is convenient Effect of inflow and increase in contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

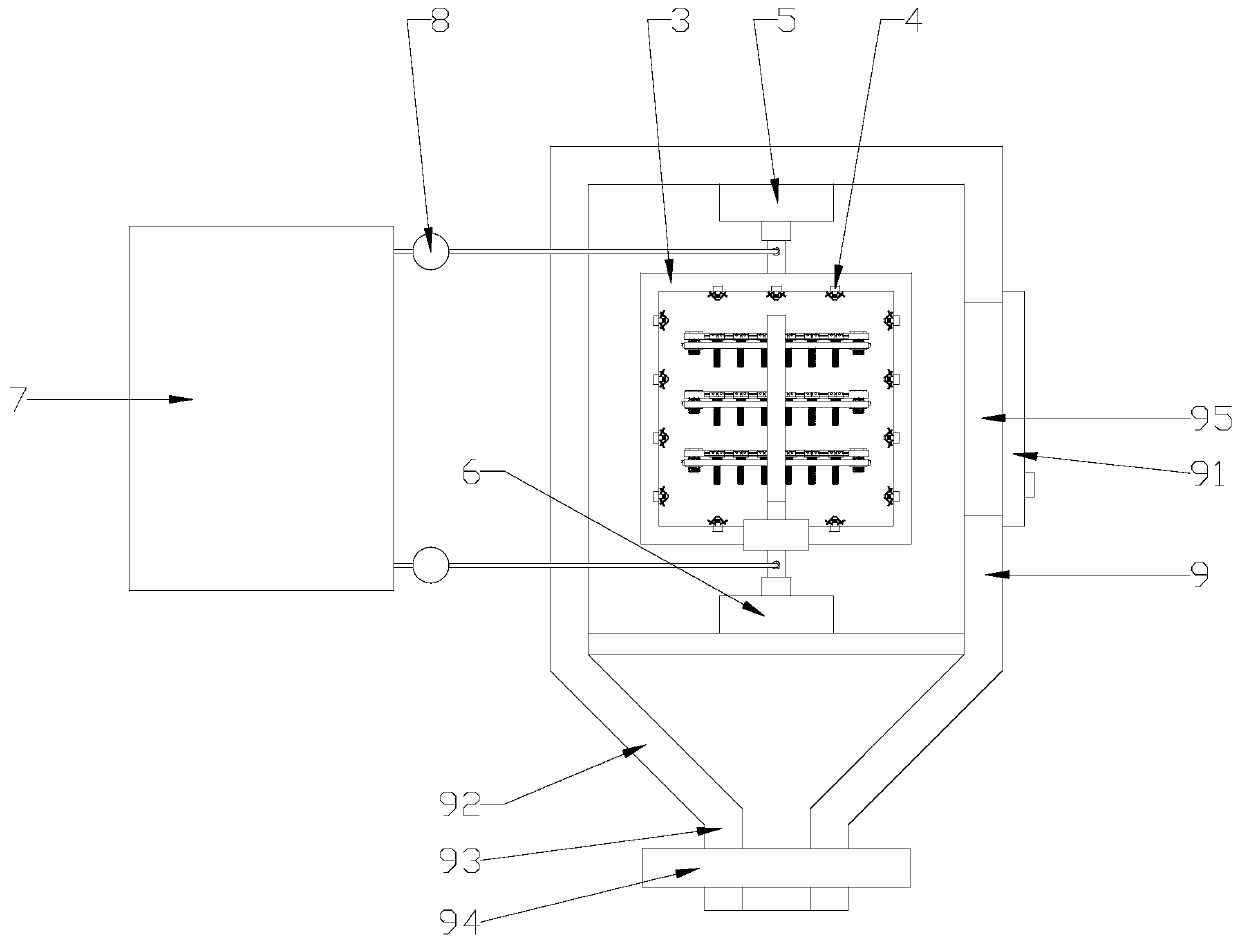

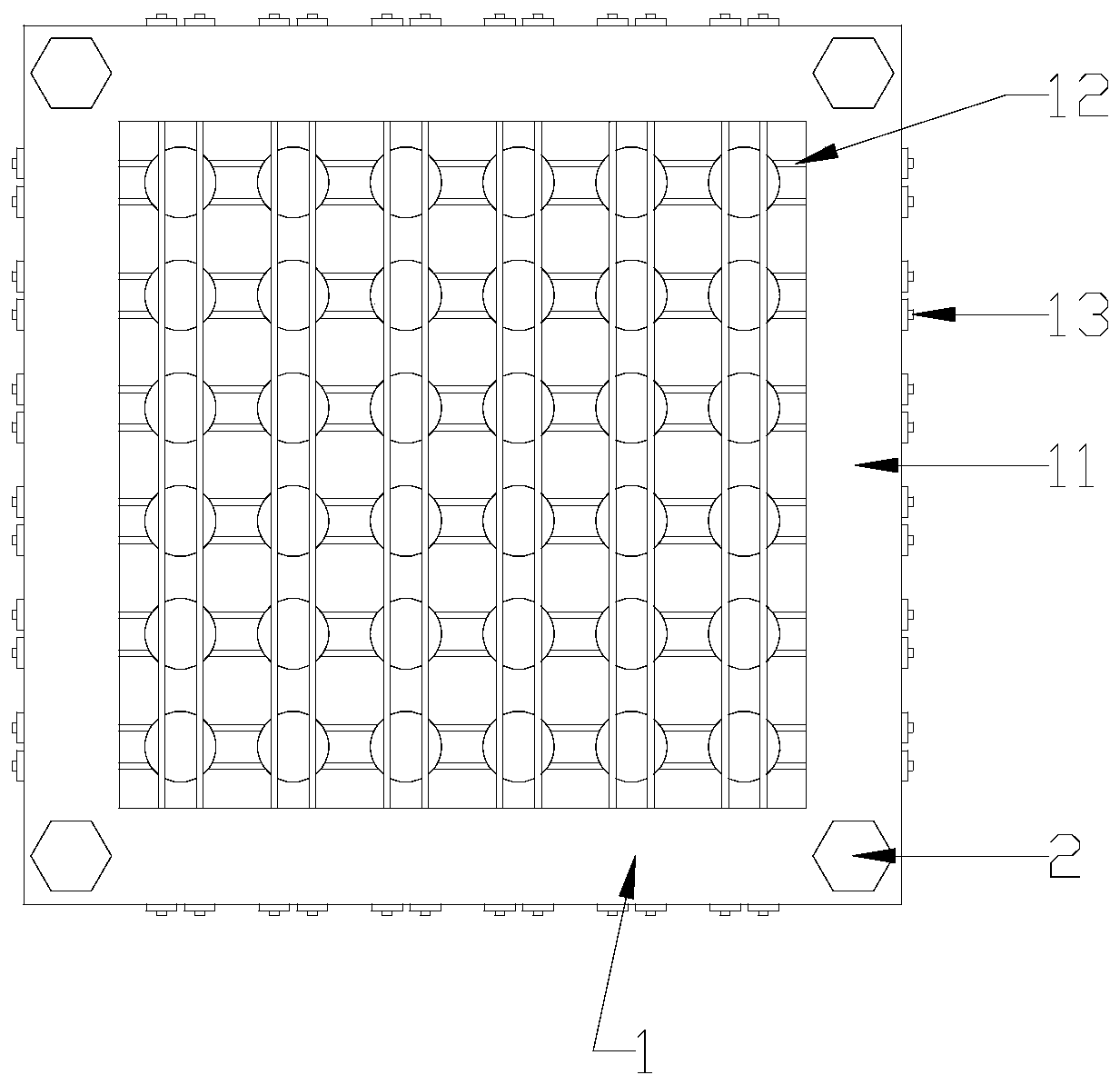

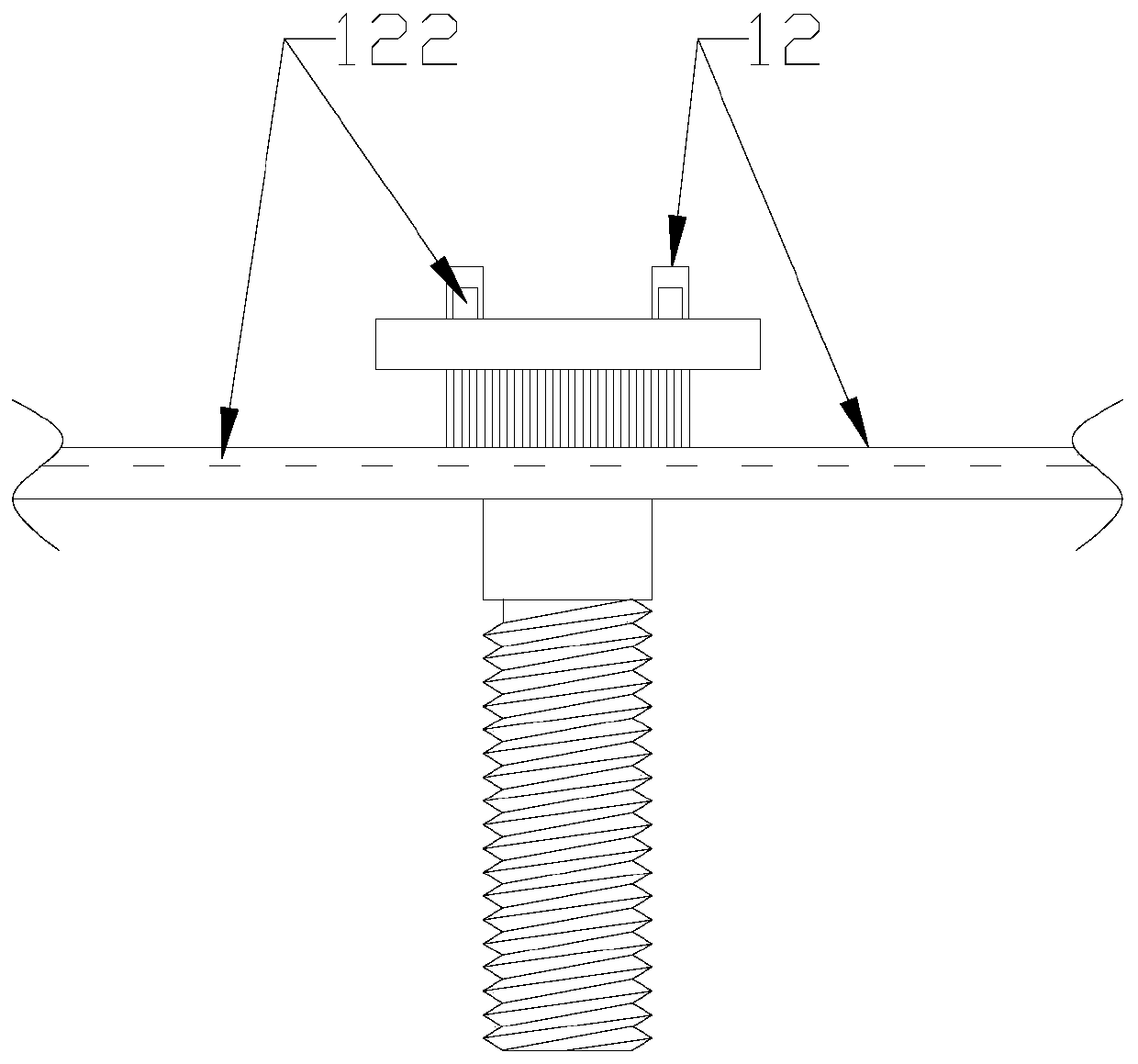

[0019] refer to Figure 1 to Figure 4 , an anti-scratch cleaning device for anti-slip hub bolts of the present invention, comprising a batch holder, a swing injector, a cleaning liquid tank 7, a pump 8 and an outer casing 9, and the batch holder includes two mutually parallel sealing plates 1 And the first bolt and nut assembly 2 that connects the two sealing plates 1 up and down. The sealing plate 1 includes a side plate 11, several limit strips 12 and a second bolt and nut assembly 13, and the side plates 11 are sequentially connected to form Rectangular frame, several limiting strips 12 are arranged in parallel between two opposite side plates 11 through the second bolt and nut assembly 13 and form a set of limiting groups two by two, inside the two sealing plates 1 The limit bars 12 are perpendicular to each other, the swing injector includes two groups of injection units, the injection unit includes an injection pipe 3, an injection head 4 and a motor 5, and the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com