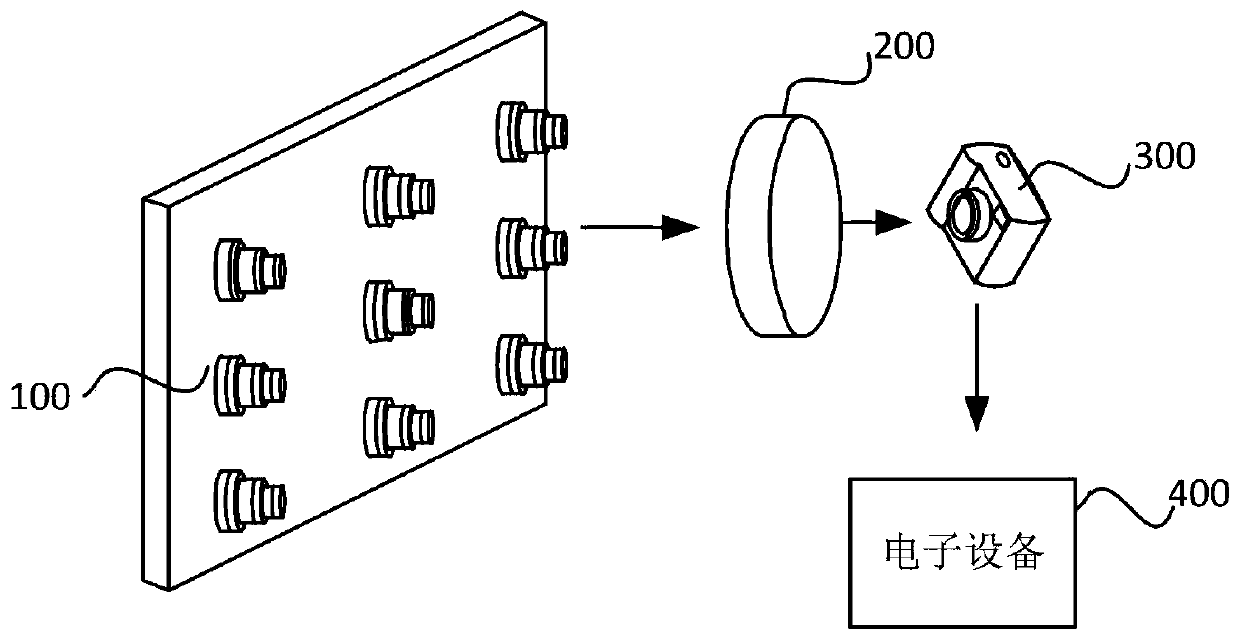

Camera calibration system and method

A camera calibration and camera technology, applied in image data processing, instruments, calculations, etc., can solve the problems of increasing target production costs, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

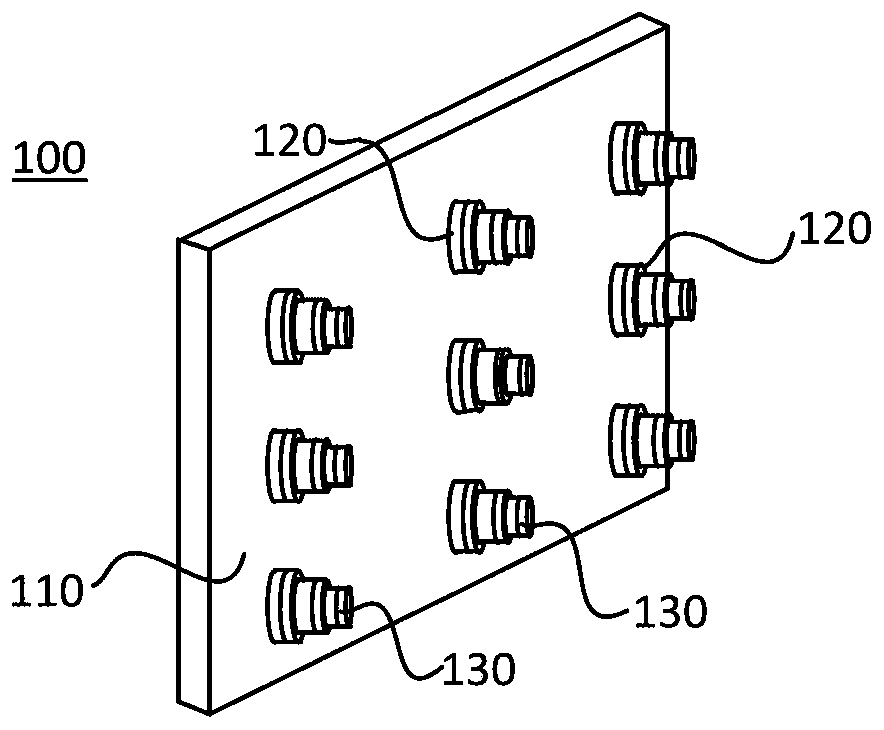

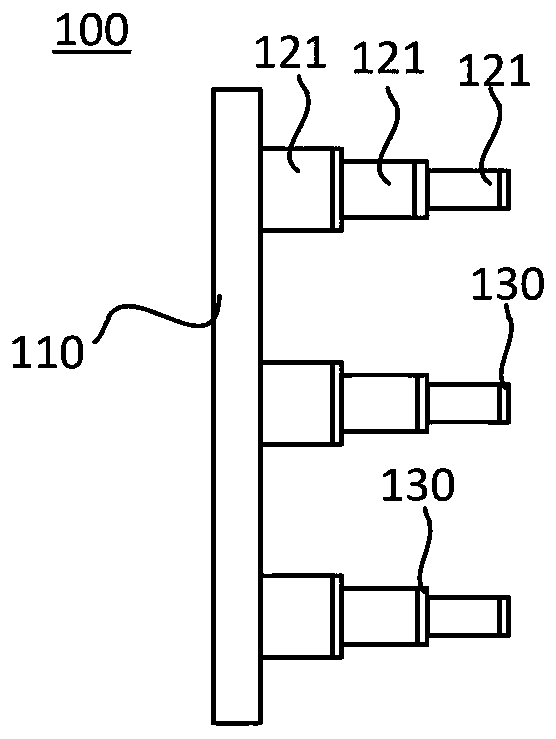

[0019] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0020] Camera calibration is one of the key technologies in machine vision, photogrammetry, 3D imaging, and image geometry correction. Its main function is to estimate the internal and external parameters of the camera. The accuracy of the calibration results and the stability of the calibration algorithm directly affect the accuracy of subsequent work. A general perspective camera can be represented by a pinhole model, and can be calibrated using perspective projection mapping and affine transformation.

[0021] The method that has been researched and matured at present is to use a planar target, and there are tool software based on the planar target, such as: Matlab t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com