Flexible duct rehabilitation construction method

A construction method and technology of flexible pipelines, which are applied in the directions of pipeline laying and maintenance, infrastructure engineering, pipes/pipe joints/fittings, etc., which can solve the problem that the structural strength of the pipeline is not strengthened, the flow area of the pipeline is reduced, and the flow rate of the pipeline is affected, etc. It can prevent the corrosion of steel sheets and water leakage at the lap joint, increase the overall structural performance and reduce the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

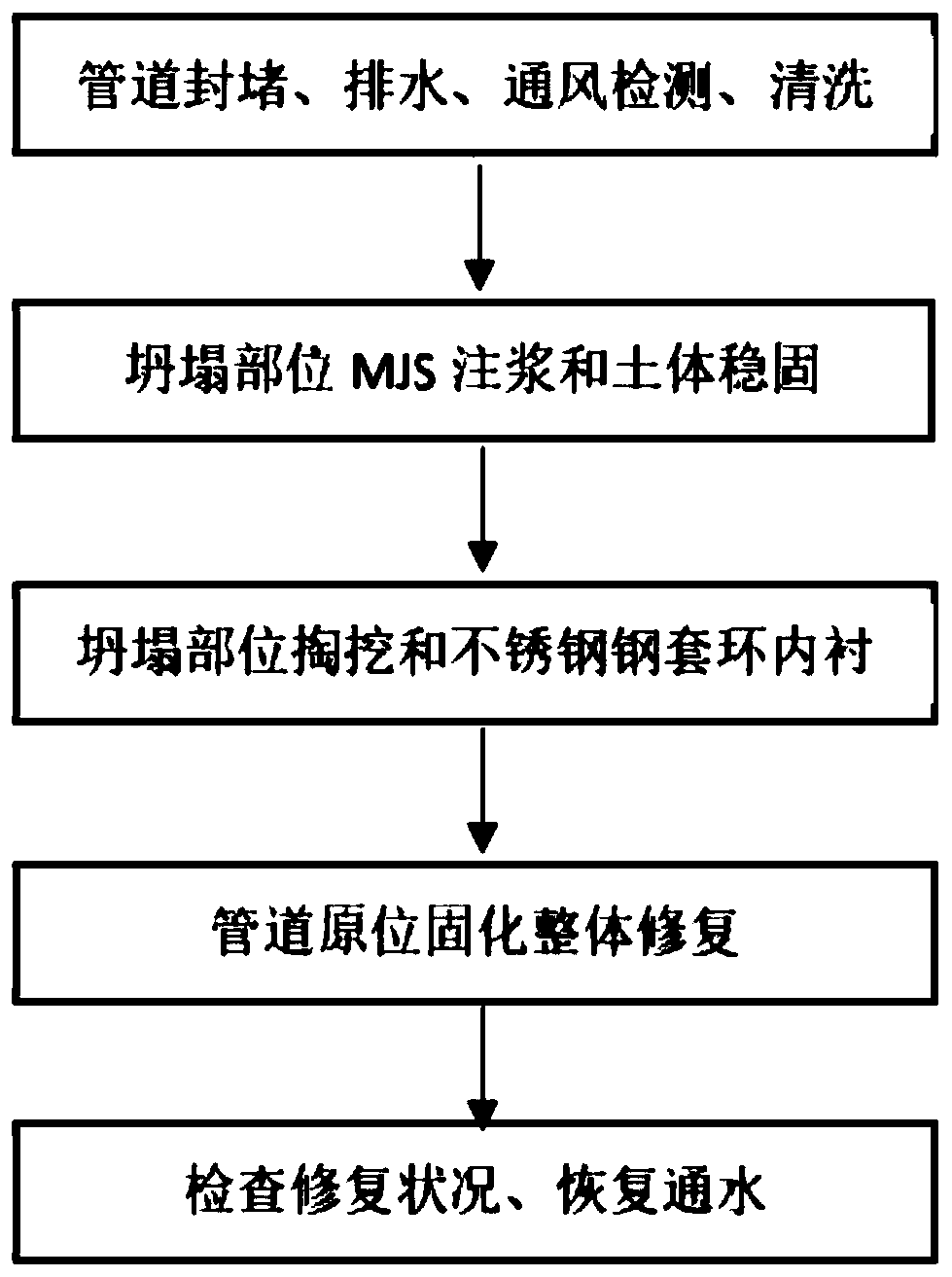

[0018] Such as figure 1 Shown, a kind of flexible pipeline repairing construction method comprises the following steps:

[0019] (1) The upstream and downstream of the pipeline to be repaired by divers are sealed with airbags, and the pressure of the airbags is measured regularly. After the sealing is completed, the pipeline is pumped, toxic and harmful gases are detected, ventilated and the pipeline is cleaned;

[0020] (2) The outer soil of the pipeline at the deformed and collapsed part is reinforced by the large-diameter MJS grouting process to facilitate the excavation of the deformed and collapsed part.

[0021] (3) The construction personnel enter the interior of the pipeline and excavate with a foot of 300mm. After each foot of excavation, two semicircular stainless steel sheets are used to assemble a round pipe and fix it firmly to form an inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com