Safety valve of vacuum system

A vacuum system and safety valve technology, applied in safety valves, valve details, balance valves, etc., can solve problems such as uncommon interfaces and unfavorable pressure regulation, and achieve the effects of ensuring universal interface, saving time and cost, and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

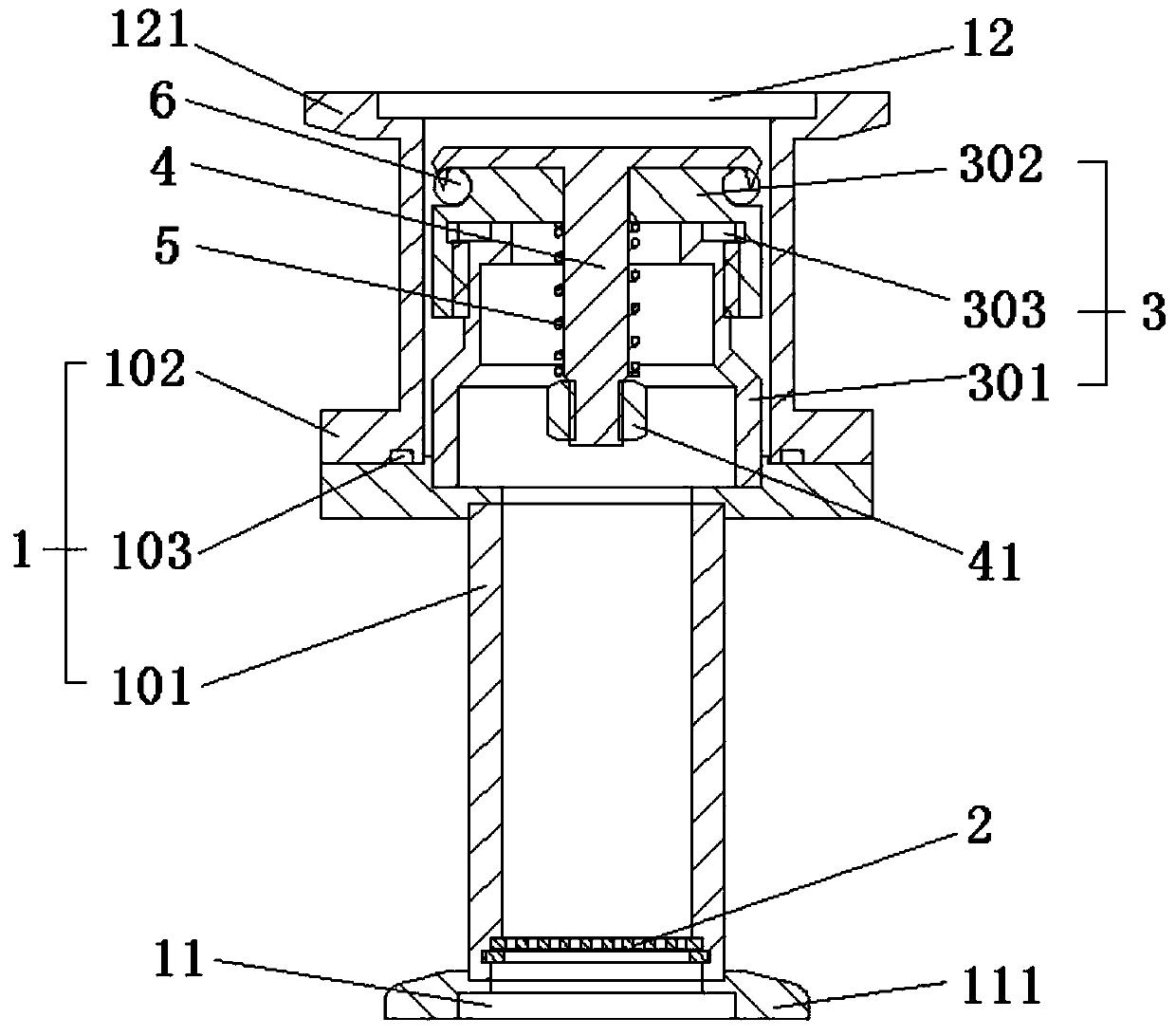

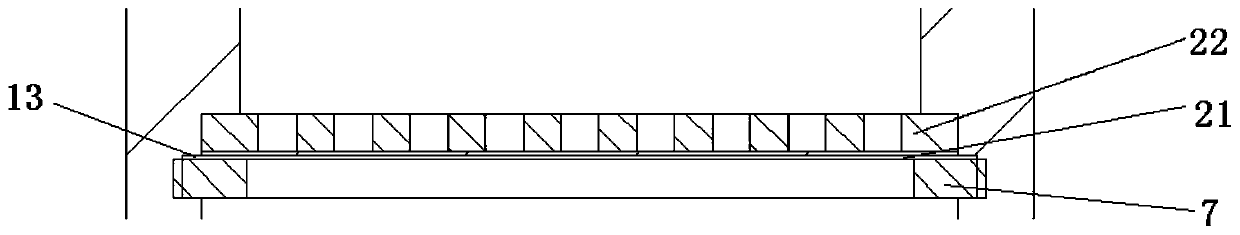

[0033] The vacuum system safety valve, as shown in the figure, includes a valve seat 1 and a valve core 3. The valve core 3 is movable and controls the opening and closing of the installed valve. The valve seat 1 includes an air inlet 11 and an air outlet 12. The inlet of the valve seat 1 A filter screen 2 is installed at the air port 11, and the filter screen 2 includes a fine filter screen 21 and a coarse filter screen 22.

[0034] The fine filter screen 21 and the coarse filter screen 22 are arranged in sequence along the gas flow direction, and the fine filter screen 21 is a 150-mesh stainless steel filter screen.

[0035] The fine filter 21 is a 150-mesh stainless steel filter, which is combined with the coarse filter 22 to form the filter system of the safety valve, which is used to shield solid impurities from falling into the safety valve body and prevent solid impurities from affecting the mechanical action of the safety valve; Clean to avoid sealing O-ring contaminat...

Embodiment 2

[0038] Same as the embodiment, the difference is that the air inlet 11 and the air outlet 12 are respectively equipped with an inlet flange interface 111 and an air outlet flange interface 121, the inlet flange interface 111 is a vacuum KF25 interface, and the air outlet flange interface 121 is a vacuum KF40 interface.

[0039] Its interface adopts vacuum KF interface, and the interface adopts standard fluorine rubber O-ring and stainless steel center bracket cage to ensure long-term airtightness and high temperature resistance; after using KF interface, it is guaranteed that the interface of the vacuum system is universal. It simplifies the process of vacuum system design and safety modification.

Embodiment 3

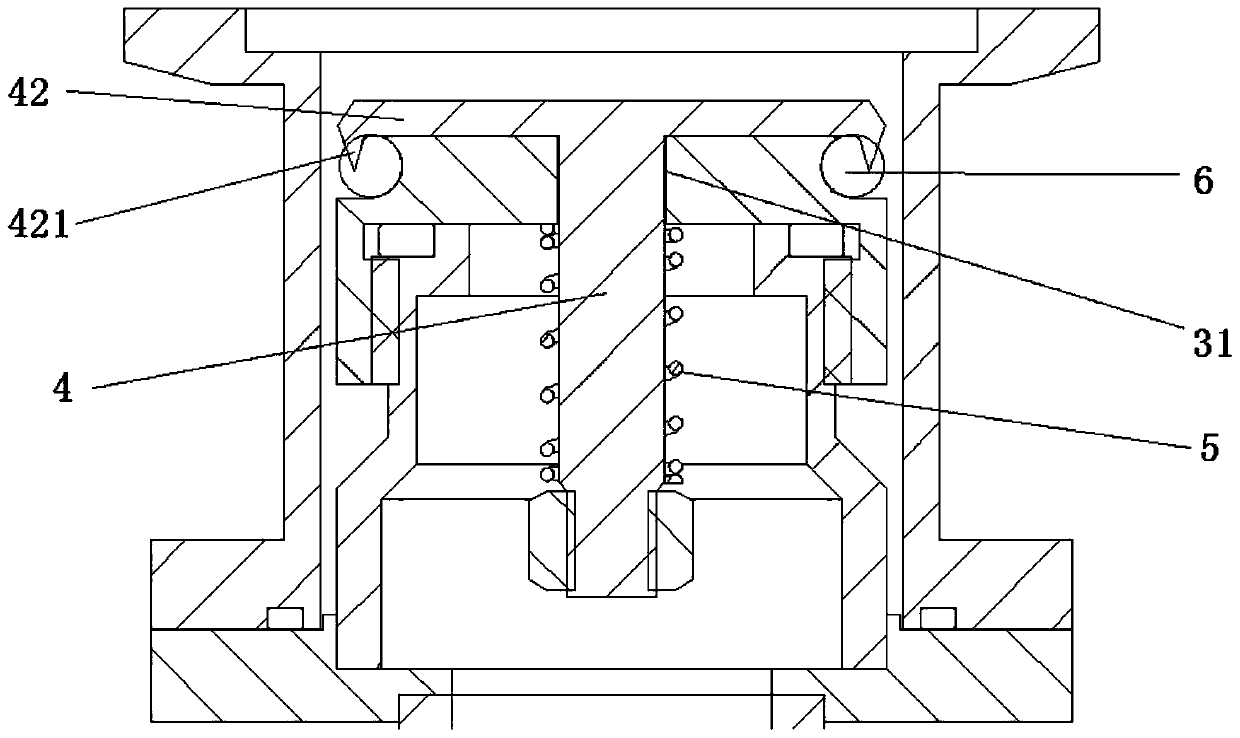

[0041] The same as the embodiment, the difference is that the valve core 3 is fixed in the valve seat 1, and the valve core 3 is provided with a vertically arranged exhaust hole 31, and the ejector rod 4 is installed in the exhaust hole 31, and the ejector rod 4 is close to the inlet. One end of the air port 11 is defined as the lower end, the other end of the ejector rod 4 is defined as its upper end, a sealing ring 6 is installed on the valve core 1, and a spring 5 sleeved on the ejector rod 4 is also included, and the lower end of the spring 5 is connected to the ejector rod. 4 The lower end is in contact, the upper end of the spring 5 is in contact with the spool 3 and pulls the upper end of the ejector rod 4 to press down on the sealing ring 6.

[0042]The lower end of the push rod 4 is provided with an external thread, and the lower end of the push rod 4 is equipped with an adjusting nut 41 cooperating with the external thread, and the lower end of the spring 5 contacts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com