Pearl fiber cleaning and drying device

A drying device and pearl fiber technology, applied in liquid/gas/steam fiber/sliver/roving treatment, liquid/gas/steam removal by air jet method, continuous processing of textile materials, etc., can solve the problem of reducing production efficiency, Low cleaning efficiency, troublesome handling back and forth, etc., to achieve the effect of accelerating gas flow, improving cleanliness, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

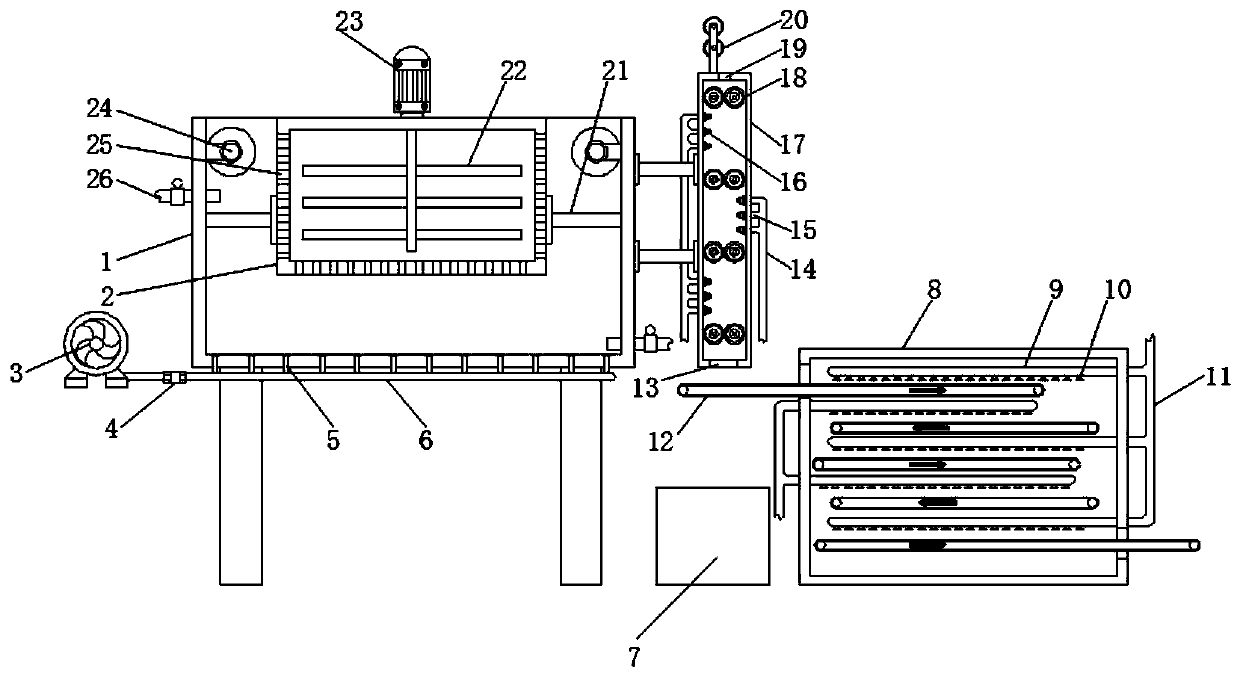

[0027] Embodiment one, with reference to Figure 1-4 , a pearl fiber cleaning and drying device, comprising a cleaning box 1 and a flushing box 17, the inside of the cleaning box 1 is fixedly connected with a stirring box 2 through a support rod 21, wherein the surface of the stirring box 2 is provided with a water permeable hole 25, and the water permeable hole 25 Evenly set on the surface of the mixing box 2 to facilitate the passage of water, and a stirring motor 23 is fixedly installed at the center of the top surface of the mixing box 2, and the inside of the mixing box 2 is provided with a stirring paddle 22, and the top surface of the stirring paddle 22 runs through the top surface of the mixing box 2 and The output end of the stirring motor 23 is connected, and the stirring box 2 wraps the stirring paddle 22 to prevent the pearl fibers from entanglement with the stirring paddle 22. The inner wall of the cleaning box 1 is equipped with a second guide roller 24, and the s...

Embodiment 2

[0028] Embodiment two, refer to figure 1 , a drying box 8 is arranged obliquely below the washing box 17, and a conveyor belt 12 is arranged in a staggered manner inside the drying box 8, and the transmission direction of the conveyor belt 12 is in the figure 1It has been marked with an arrow, and a hot air pipe 9 is erected above the conveyor belt 12, and the bottom surface of the hot air pipe 9 is provided with a hot air outlet 10, and the other end of the hot air pipe 9 runs through the drying box 8 and is connected with the air delivery pipe 11. Wherein, the air delivery pipe 11 is connected through the outlet end of the hot air blower, the uppermost conveyor belt 12 runs through the drying box 8 and extends below the outlet 13, and the lowermost conveyor belt 12 runs through the drying box 8 and extends out of the drying box 8, After rinsing, the pearl fiber is sent out of the wire outlet 13 by the transfer roller 18, and gradually falls to the top surface of the conveyor...

Embodiment 3

[0029] Embodiment three, refer to figure 1 A water receiving tank 7 is placed directly below the outlet 13 to facilitate access to the flushing water left at the outlet 13, and the water receiving tank 7 is connected through a pipeline with the sewage treatment equipment, which is not shown in the common structure diagram.

[0030] Working principle: move the device to a suitable position, connect the power supply and the external clean water source for the device, connect the hot air blower for the air duct 11, and pass one end of the soaked pearl fiber through the second guide roller 24 on the left and Between the stirring box 2, and around the bottom surface of the stirring box 2, pass between the second guide roller 24 on the other right side and the stirring box 2, and pass between the first guide roller 20 and pass between the transmission rollers 18 to complete The threading process, after the threading process is completed, the cleaning and rinsing work can be started,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com