Preparation method of electronic circuit board cleaning agent

A technology for electronic circuit boards and cleaning agents, applied in cleaning methods and utensils, cleaning methods using liquids, detergent compounding agents, etc., can solve the problems of corrosion and rust, incomplete cleaning of electronic circuit boards, etc. Dispersion ability, the effect of ensuring the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

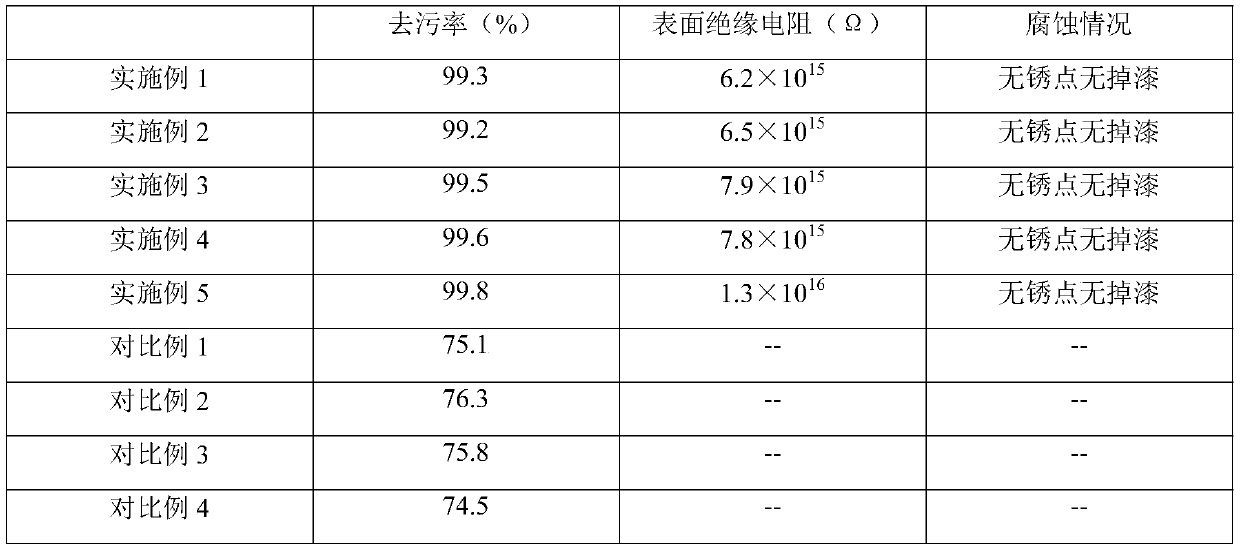

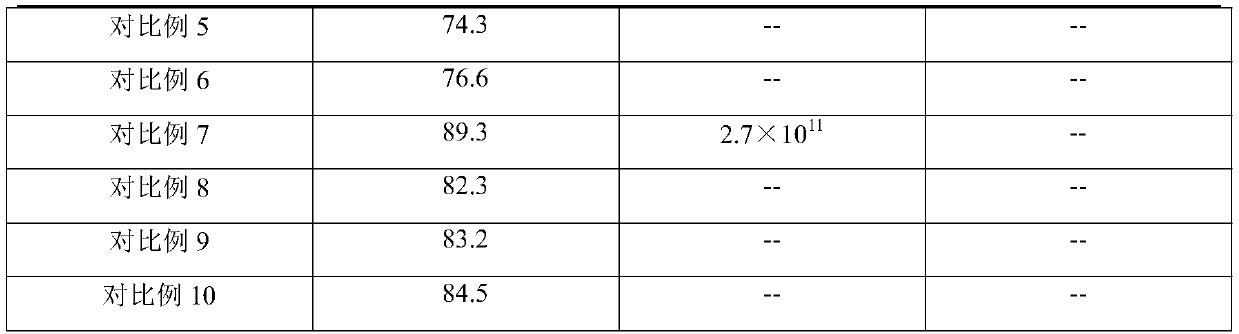

Examples

Embodiment 1

[0031] A preparation method of cleaning agent for electronic circuit board, in parts by weight, first mix 3 parts of ethylene glycol monomethyl ether, 2 parts of 1-hydroxyl-ethanesulfonic acid and 8 parts of polyol solvent to obtain the prepared Mixed liquid; then dissolve 5 parts of polyethylene glycol oleate, 3 parts of dioctyl sulfosuccinate sodium salt, 2 parts of sodium secondary alkyl sulfonate, 2 parts of alkyl polyglycosides, and 1 part of potassium pyrophosphate in 100 2 parts of deionized water, add the premix solution while stirring, and stir evenly; then 2 parts of N-methyl-2-pyrrolidone are evenly added dropwise in 20 minutes, and after the dropwise addition is completed, stir for 20 minutes, and then add 5 parts of modified Silica gel and 4 parts of 2,2'-azobisisobutylamidine dihydrochloride were refluxed and reacted under a nitrogen atmosphere to obtain the cleaning agent for electronic circuit boards.

[0032] The preparation method of the premixed solution is ...

Embodiment 2

[0040] A preparation method of a cleaning agent for electronic circuit boards, in parts by weight, firstly mix 4 parts of ethylene glycol monomethyl ether, 3 parts of 1-hydroxy-ethanesulfonic acid and 12 parts of polyol solvents to obtain the prepared Mixed solution; then 8 parts of polyethylene glycol oleate, 5 parts of dioctyl sulfosuccinate sodium salt, 3 parts of secondary alkyl sodium sulfonate, 3 parts of alkyl polyglycosides, and 2 parts of potassium pyrophosphate were dissolved in 100 3 parts of deionized water, add the premixed solution while stirring, and stir evenly; then, it takes 30 minutes to evenly add 3 parts of N-methyl-2-pyrrolidone, and stir for 30 minutes after the addition is completed, then add 8 parts of modified Silica gel and 7 parts of 2,2'-azobisisobutylamidine dihydrochloride were refluxed and reacted under a nitrogen atmosphere to obtain the cleaning agent for electronic circuit boards.

[0041] The preparation method of the premix is as follows:...

Embodiment 3

[0050] A preparation method of a cleaning agent for electronic circuit boards, in parts by weight, first mix 3 parts of ethylene glycol monomethyl ether, 3 parts of 1-hydroxy-ethanesulfonic acid and 8 parts of polyol solvent to obtain the Mixed liquid; then 8 parts of polyethylene glycol oleate, 3 parts of dioctyl sulfosuccinate sodium salt, 3 parts of secondary alkyl sodium sulfonate, 2 parts of alkyl polyglycosides, and 2 parts of potassium pyrophosphate were dissolved in 100 3 parts of deionized water, add the premix solution while stirring, and stir evenly; then, it takes 20 minutes to evenly add 3 parts of N-methyl-2-pyrrolidone, and stir for 20 minutes after the dropwise addition, then add 8 parts of modified Silica gel and 4 parts of 2,2'-azobisisobutylamidine dihydrochloride were refluxed and reacted under a nitrogen atmosphere to obtain the cleaning agent for electronic circuit boards.

[0051] The preparation method of the premix is as follows: add ethylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com