A kind of hot-melt anticorrosion adhesive, hot-melt anticorrosion adhesive tape and preparation method thereof

An anti-corrosion adhesive and hot-melt technology, applied in the field of tape, can solve the problems of easy sliding, high construction cost, low rust removal level, etc., and achieve the effects of good water and air barrier, simple and convenient construction, and reduced construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The hot-melt anticorrosion glue of this embodiment 1, its preparation raw material comprises the following components by mass percentage: petrolatum 25%, styrene-isoprene-styrene synthetic rubber 25%, petroleum resin 18%, mineral oil 10% %, aluminum hydroxide 15%, antirust agent 3%, antifungal agent 3%, antioxidant 1%.

[0028] Weigh each raw material according to the above formula, heat and mix each raw material evenly at a heating temperature of 100°C, and obtain a hot-melt anticorrosion adhesive after heating.

[0029] Utilize above-mentioned hot-melt anticorrosion glue to prepare hot-melt anticorrosion adhesive tape, its preparation process is as follows:

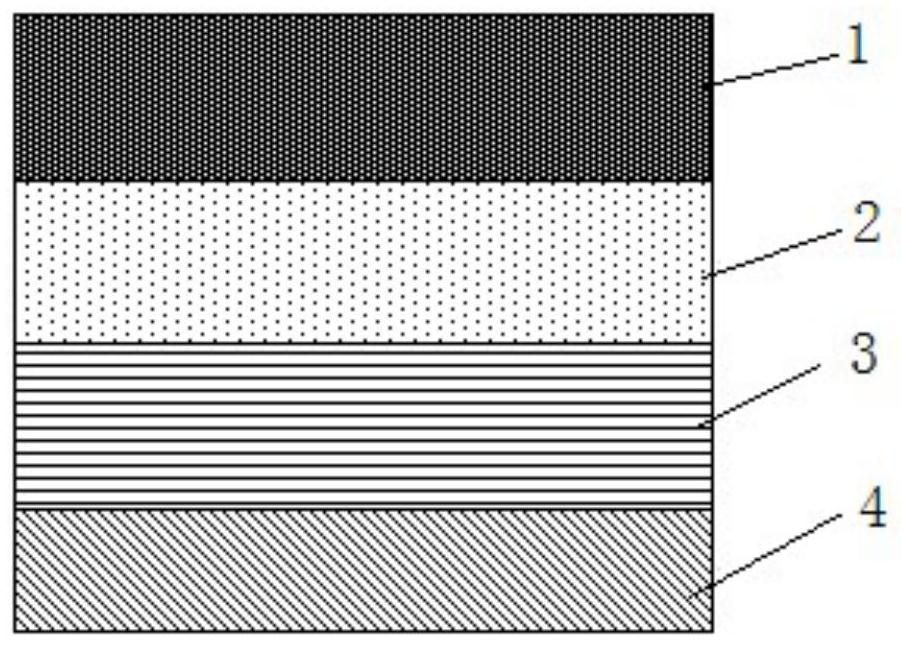

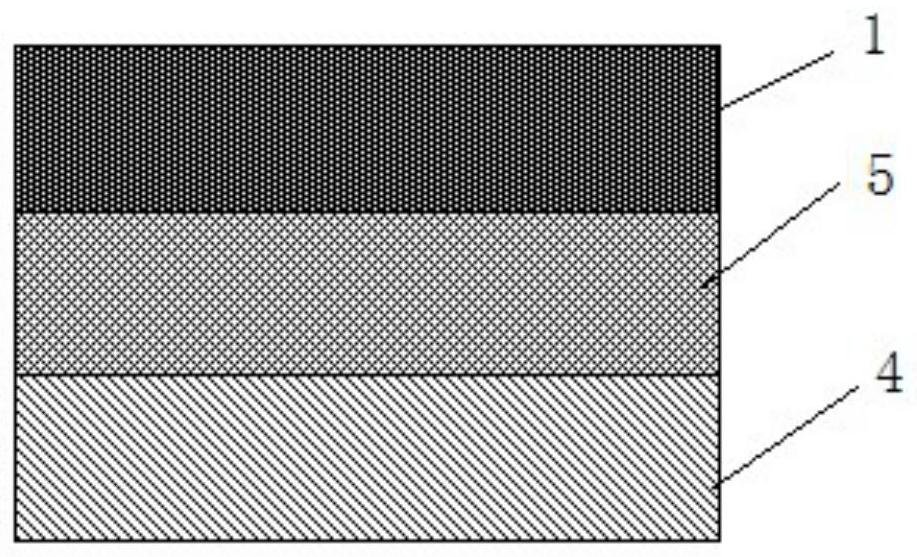

[0030] Composite the non-woven fabric and the polyethylene base material by means of heat-compression compounding, and then hot-melt-coat the prepared hot-melt anti-corrosion adhesive on the non-woven fabric to form a base material 1, a non-woven fabric 2 and a The composite anticorrosion adhesive layer of the a...

Embodiment 2

[0033] The hot-melt anticorrosion glue of this embodiment 2, its preparation raw material comprises the following components by mass percentage: petrolatum 28%, styrene-isoprene-styrene synthetic rubber 23%, petroleum resin 20%, mineral oil 10% %, aluminum hydroxide 12%, antirust agent 3%, antifungal agent 2%, antioxidant 2%.

[0034] Weigh each raw material according to the above formula, heat and mix each raw material evenly at a heating temperature of 100°C, and obtain a hot-melt anticorrosion adhesive after heating.

[0035] Utilize above-mentioned hot-melt anticorrosion glue to prepare hot-melt anticorrosion adhesive tape, its preparation process is as follows:

[0036] Composite the non-woven fabric and the polyethylene base material by means of heat-compression compounding, and then hot-melt-coat the prepared hot-melt anti-corrosion adhesive on the non-woven fabric to form a base material 1, a non-woven fabric 2 and a The composite anticorrosion adhesive layer of the a...

Embodiment 3

[0039] The hot-melt anticorrosion glue of this embodiment 3, its preparation raw material comprises the following components by mass percentage: petrolatum 30%, styrene-isoprene-styrene synthetic rubber 23%, petroleum resin 23%, mineral oil 5% %, aluminum hydroxide 10%, antirust agent 5%, antifungal agent 3%, antioxidant 1%.

[0040] Weigh each raw material according to the above formula, heat and mix each raw material evenly at a heating temperature of 100°C, and obtain a hot-melt anticorrosion adhesive after heating.

[0041] Utilize above-mentioned hot-melt anticorrosion glue to prepare hot-melt anticorrosion adhesive tape, its preparation process is as follows:

[0042] Composite the non-woven fabric and the polyethylene base material by means of heat-compression compounding, and then hot-melt-coat the prepared hot-melt anti-corrosion adhesive on the non-woven fabric to form a base material 1, a non-woven fabric 2 and a The composite anticorrosion adhesive layer of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com