Odorless antistatic PVC composite material and preparation method thereof

A composite material and antistatic technology, applied in the ABS field, can solve problems such as poor heat resistance, easy deformation, and easy cracking, and achieve high toughening efficiency and rigid performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

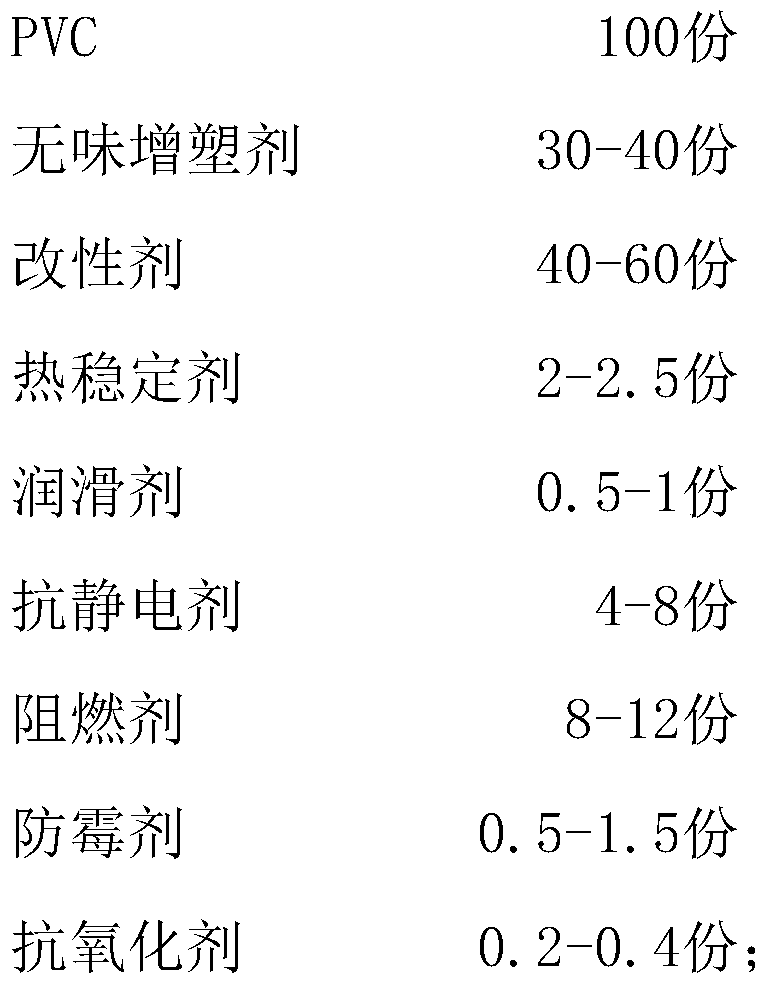

[0027] A kind of tasteless antistatic PVC composite material, comprises the raw material of following parts by weight:

[0028]

[0029] The preparation method of described modifying agent comprises the steps:

[0030] (1) 10 parts by weight of nano silicon dioxide, 12 parts by weight of methyl methacrylate, 4 parts by weight of acrylic acid and 1 part by weight of OP10 and 50 parts by weight of water are mixed and emulsified to obtain a seed emulsion;

[0031] (2) Add 0.1 parts by weight of an initiator to the seed emulsion, heat up to 70°C, and keep the temperature for 40 minutes to obtain a primary polymerization solution;

[0032] (3) Add 10 parts by weight of styrene, 5 parts by weight of butyl acrylate and 0.1 part by weight of an initiator to the primary polymerization solution, heat up to 70° C., and keep warm for 40 minutes to obtain a secondary polymerization solution;

[0033] (4) adding magnesium sulfate to the secondary polymerization solution to break the emu...

Embodiment 2

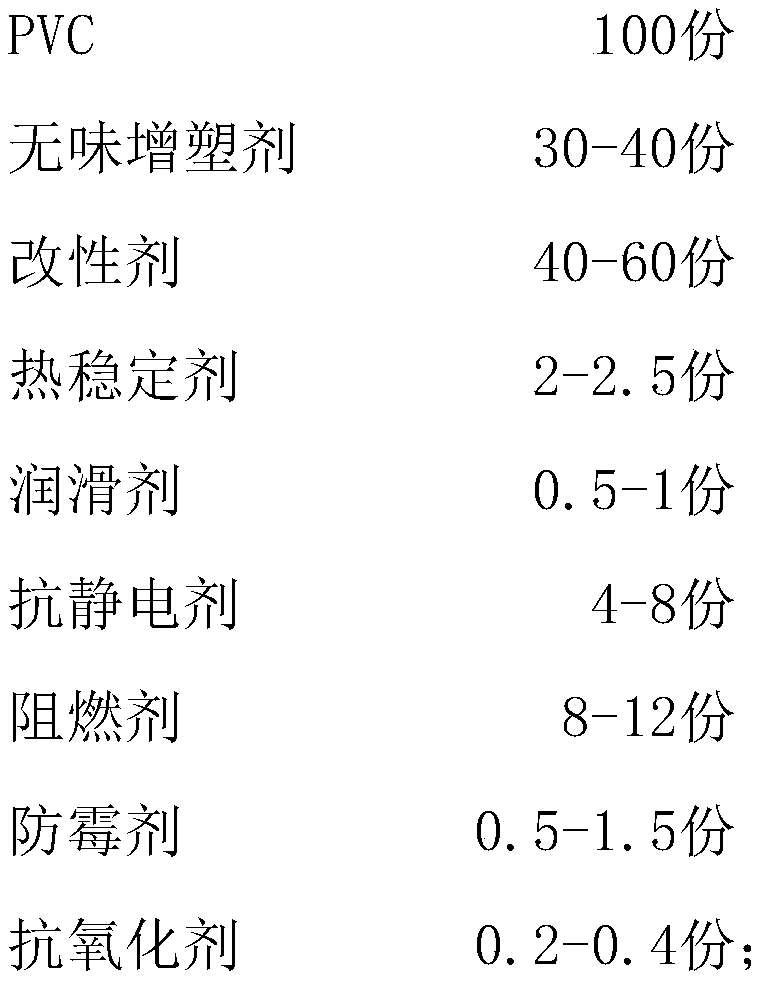

[0045] A kind of tasteless antistatic PVC composite material, comprises the raw material of following parts by weight:

[0046]

[0047] The preparation method of described modifying agent comprises the steps:

[0048] (1) 10 parts by weight of nano silicon dioxide, 12 parts by weight of methyl methacrylate, 4 parts by weight of acrylic acid and 1 part by weight of OP10 and 50 parts by weight of water are mixed and emulsified to obtain a seed emulsion;

[0049] (2) Add 0.1 parts by weight of an initiator to the seed emulsion, heat up to 60° C., and keep warm for 30 minutes to obtain a primary polymerization solution;

[0050] (3) Add 10 parts by weight of styrene, 5 parts by weight of butyl acrylate and 0.1 part by weight of an initiator to the primary polymerization solution, heat up to 60° C., and keep the temperature for 30 minutes to obtain a secondary polymerization solution;

[0051] (4) adding magnesium sulfate to the secondary polymerization solution to break the e...

Embodiment 3

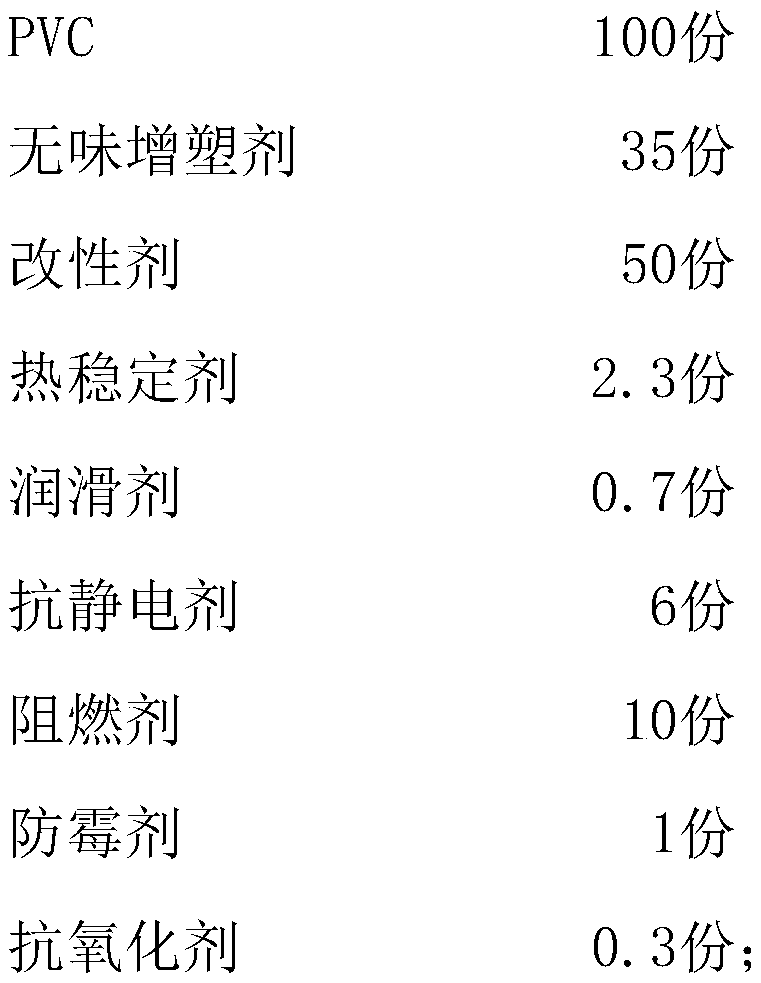

[0063] A kind of tasteless antistatic PVC composite material, comprises the raw material of following parts by weight:

[0064]

[0065]

[0066] The preparation method of described modifying agent comprises the steps:

[0067] (1) 10 parts by weight of nano silicon dioxide, 12 parts by weight of methyl methacrylate, 4 parts by weight of acrylic acid and 1 part by weight of OP10 and 50 parts by weight of water are mixed and emulsified to obtain a seed emulsion;

[0068] (2) Add 0.1 parts by weight of an initiator to the seed emulsion, heat up to 80° C., and keep warm for 50 minutes to obtain a primary polymerization solution;

[0069] (3) Add 10 parts by weight of styrene, 5 parts by weight of butyl acrylate and 0.1 part by weight of an initiator to the primary polymerization solution, heat up to 80° C., and keep warm for 50 minutes to obtain a secondary polymerization solution;

[0070] (4) adding magnesium sulfate to the secondary polymerization solution to break the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com