3D printing technology based sample deformation control method

A technology of 3D printing and sample control, applied in the field of 3D printing, can solve the problem of uncontrollable dynamic changes of deformation, and achieve the effect of various recovery effects, good controllability, and realization of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

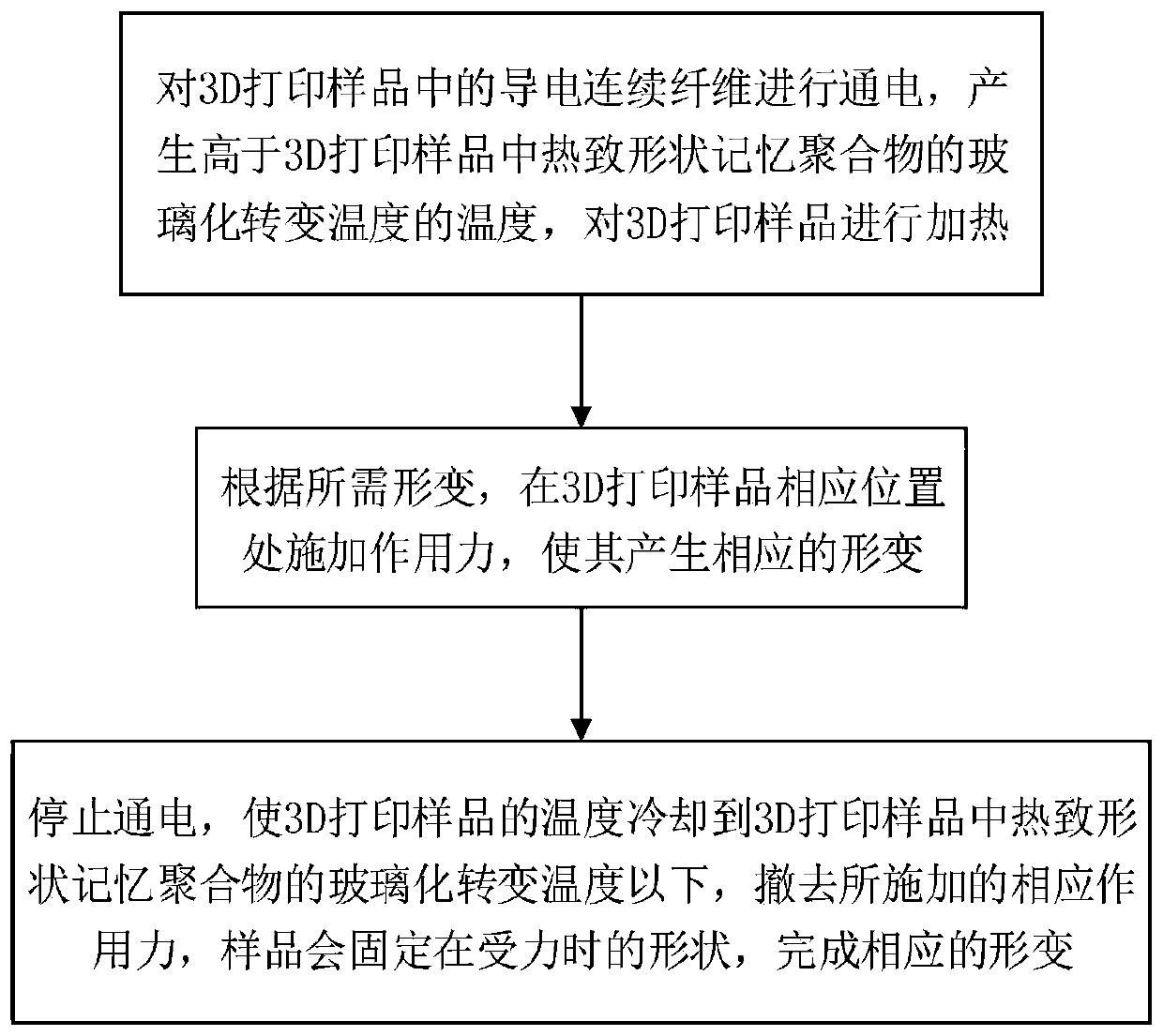

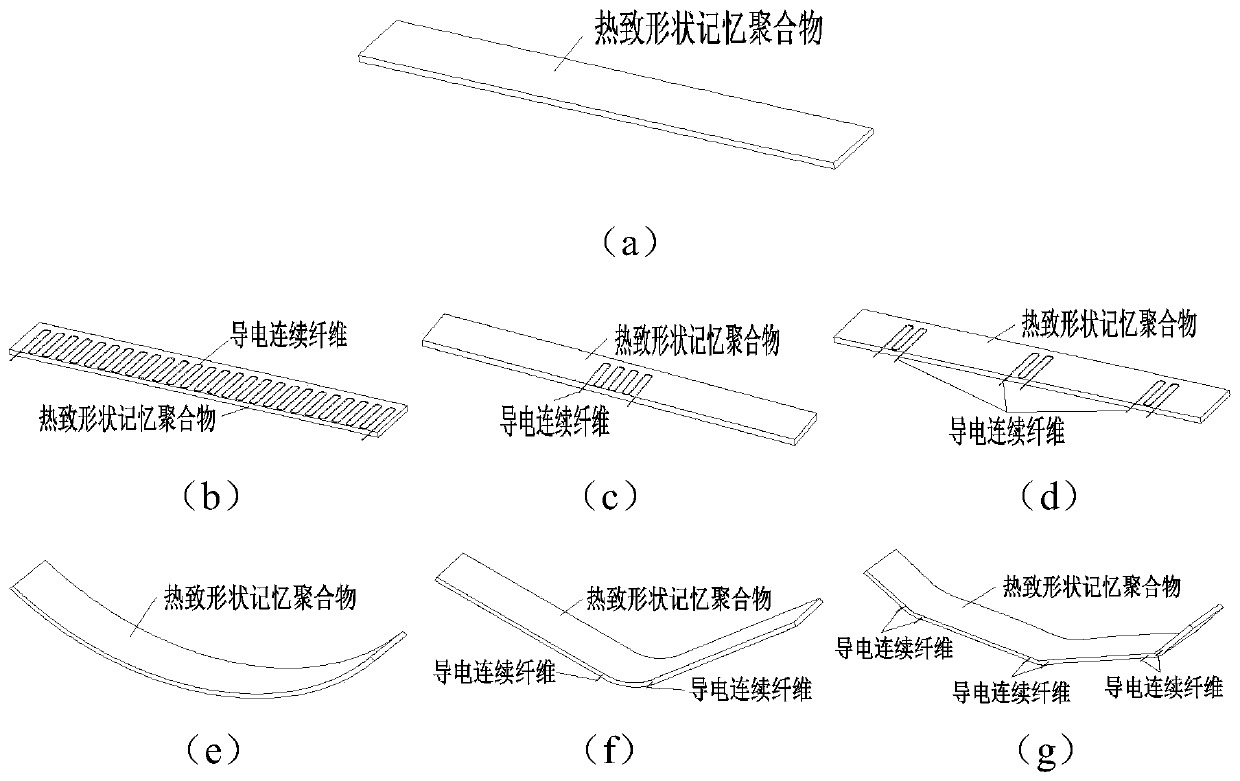

[0048] In this embodiment, the sample required by the user is as figure 2 The rectangular sheet shown in (a) of the figure, at the same time, the user requires the rectangular sheet to be able to achieve different degrees of bending and bending deformation at different positions. Specifically, the above-mentioned rectangular sheet includes conductive continuous fibers and thermotropic shape memory polymers, wherein the surface of the conductive continuous fibers is coated with thermotropic shape memory polymers.

[0049] In order to get as figure 2 For the rectangular sheet shown in (a), first determine the printing path of the thermotropic shape memory polymer according to the shape characteristics of the required sample; then determine the position of the conductive continuous fiber according to the variability requirements of the required rectangular sheet , shape and density distribution, and further determine the printing path of the conductive continuous fiber; specif...

Embodiment 2

[0067] In this embodiment, the sample required by the user is a cross-shaped slice, such as Figure 4 As shown in (a) in the figure, it contains four branches, which are respectively branch 1, branch 2, branch 3, and branch 4. The user requires that after the four branches are bent, the four branches The original shape can be restored in a certain order.

[0068] Specifically, the above-mentioned cross-shaped sheet 3D printing sample includes conductive continuous fibers and thermotropic shape memory polymers, wherein the surface of the conductive continuous fibers is coated with thermotropic shape memory polymers. Specifically, the following methods are used: first, according to the shape characteristics of the required sample, determine the printing path of the thermotropic shape memory polymer; then, according to the variability requirements of the required sample, determine the position and shape of the conductive continuous fiber, and further determine the conductive cont...

Embodiment 3

[0077] By changing the location distribution of the conductive fibers in the 3D printed sample, the shape memory deformation of the sample can be controlled.

[0078] Firstly, the conductive continuous fibers in the rectangular sheets with different positions of the conductive continuous fibers are heated respectively to cause temporary deformation to obtain horizontally expanded rectangular sheets.

[0079] In this example, for shapes such as figure 2 The rectangular sheet shown in (e) is also temporarily deformed by using the method for controlling sample deformation provided by the first aspect of the present invention. Specifically, electrifying the conductive continuous fibers in the rectangular sheet in which the conductive continuous fibers exhibit different distributions generates heat higher than the glass transition temperature of the thermotropic shape memory polymer in the rectangular sheet, and heats the rectangular sheet; wherein, each Rectangular flakes have t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com