Manufacturing method for PVC fittings

A technology of accessories and finished accessories, applied in applications, household appliances, other household appliances, etc., can solve the problems of unutilized waste products, low thermal deformation temperature, and low insulation flame retardancy, and achieve high yield, high quality, The effect of high insulation flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

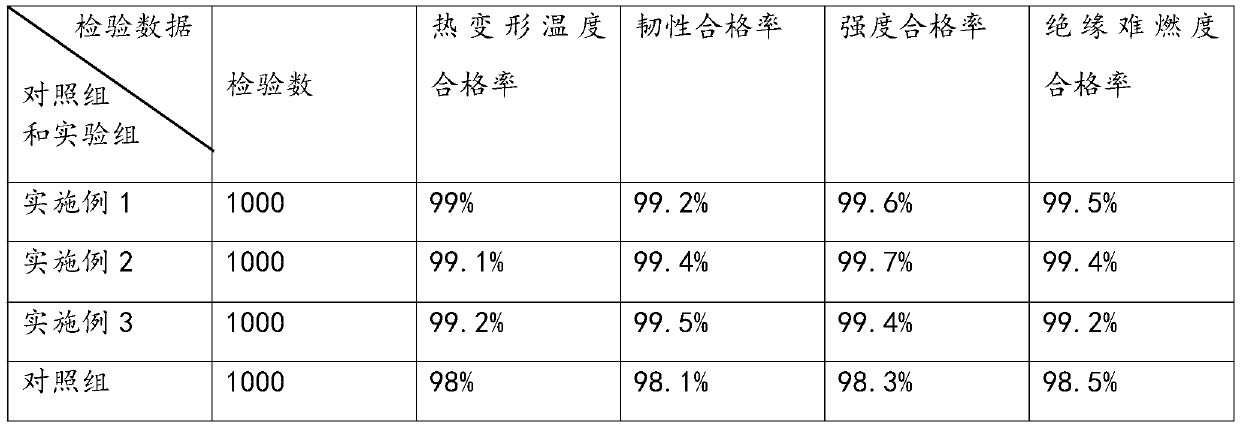

Examples

Embodiment 1

[0021] A preparation method for PVC accessories, comprising the following steps:

[0022] Step 1, material preparation: select qualified powder as raw material, and use a mixer to stir and mix;

[0023] Step 2, granulation: use a granulator to make the mixed powder into granules;

[0024] Step 3, injection: use an injection molding machine to heat and melt the particles, and apply high pressure to the melted particles, so that the melted particles are injected into the pipe fitting mold and filled with the pipe fitting mold;

[0025] Step 4, mold closing and pressure keeping: after the melted particles are injected into the pipe fitting mold, the mold is cooled to make the PVC fittings cool and form;

[0026] Step 5, open the mold and take the product: when the PVC parts are cooled and formed, open the mold to take out the finished parts, and do a preliminary inspection on the finished parts, and directly eliminate the unqualified products;

[0027] Step 6: Packing and wareh...

Embodiment 2

[0036] A preparation method for PVC fittings, characterized in that it comprises the following steps:

[0037] Step 1, material preparation: select qualified powder as raw material, and use a mixer to stir and mix;

[0038] Step 2, granulation: use a granulator to make the mixed powder into granules;

[0039] Step 3, injection: use an injection molding machine to heat and melt the particles, and apply high pressure to the melted particles, so that the melted particles are injected into the pipe fitting mold and filled with the pipe fitting mold;

[0040] Step 4, mold closing and pressure keeping: after the melted particles are injected into the pipe fitting mold, the mold is cooled to make the PVC fittings cool and form;

[0041] Step 5, open the mold and take the product: when the PVC parts are cooled and formed, open the mold to take out the finished parts, and do a preliminary inspection on the finished parts, and directly eliminate the unqualified products;

[0042] Step...

Embodiment 3

[0051] A preparation method for PVC fittings, characterized in that it comprises the following steps:

[0052] Step 1, material preparation: select qualified powder as raw material, and use a mixer to stir and mix;

[0053] Step 2, granulation: use a granulator to make the mixed powder into granules;

[0054] Step 3, injection: use an injection molding machine to heat and melt the particles, and apply high pressure to the melted particles, so that the melted particles are injected into the pipe fitting mold and filled with the pipe fitting mold;

[0055] Step 4, mold closing and pressure keeping: after the melted particles are injected into the pipe fitting mold, the mold is cooled to make the PVC fittings cool and form;

[0056] Step 5, open the mold and take the product: when the PVC parts are cooled and formed, open the mold to take out the finished parts, and do a preliminary inspection on the finished parts, and directly eliminate the unqualified products;

[0057] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com