Diffusion bonding tool and method special for copper steel

A technology of diffusion connection and diffusion welding, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as joint strength and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

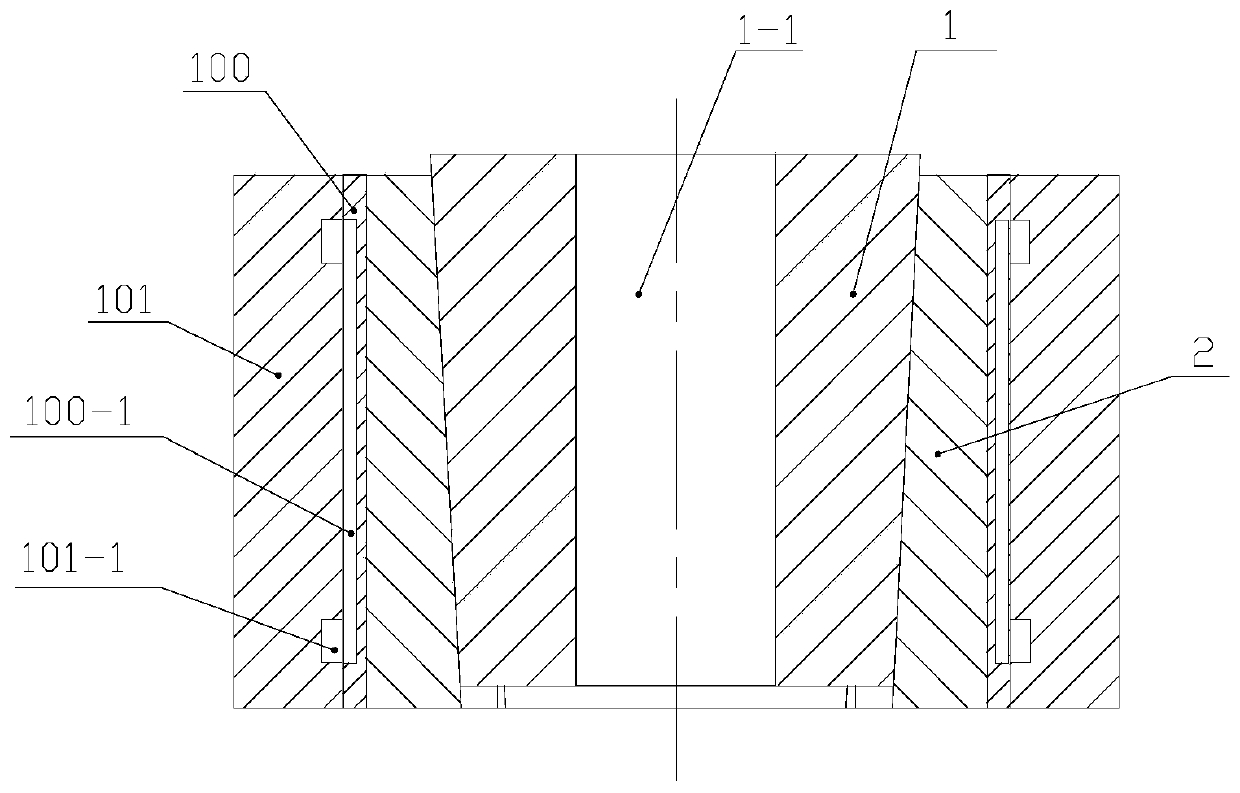

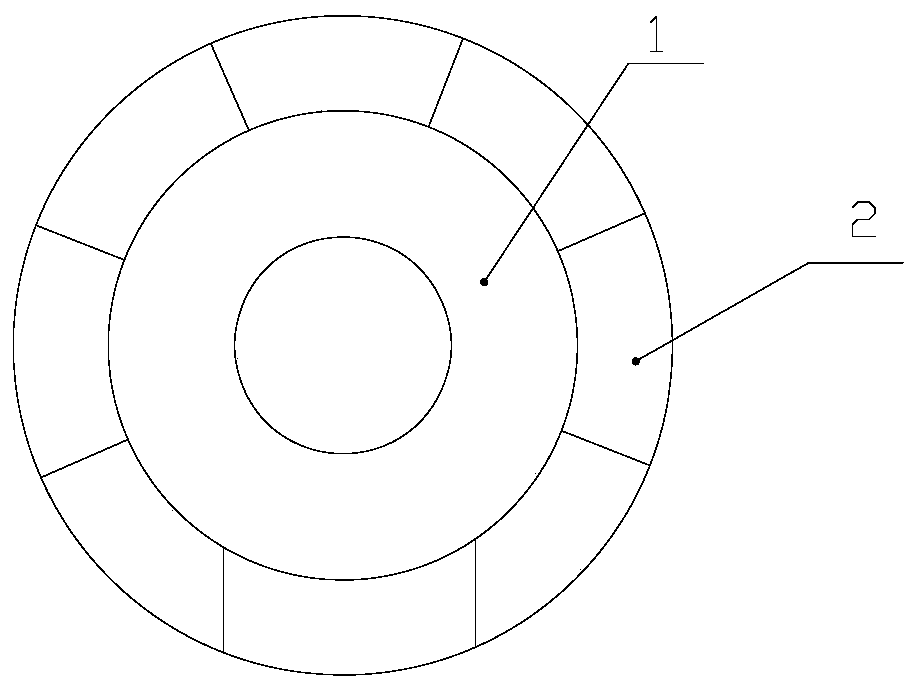

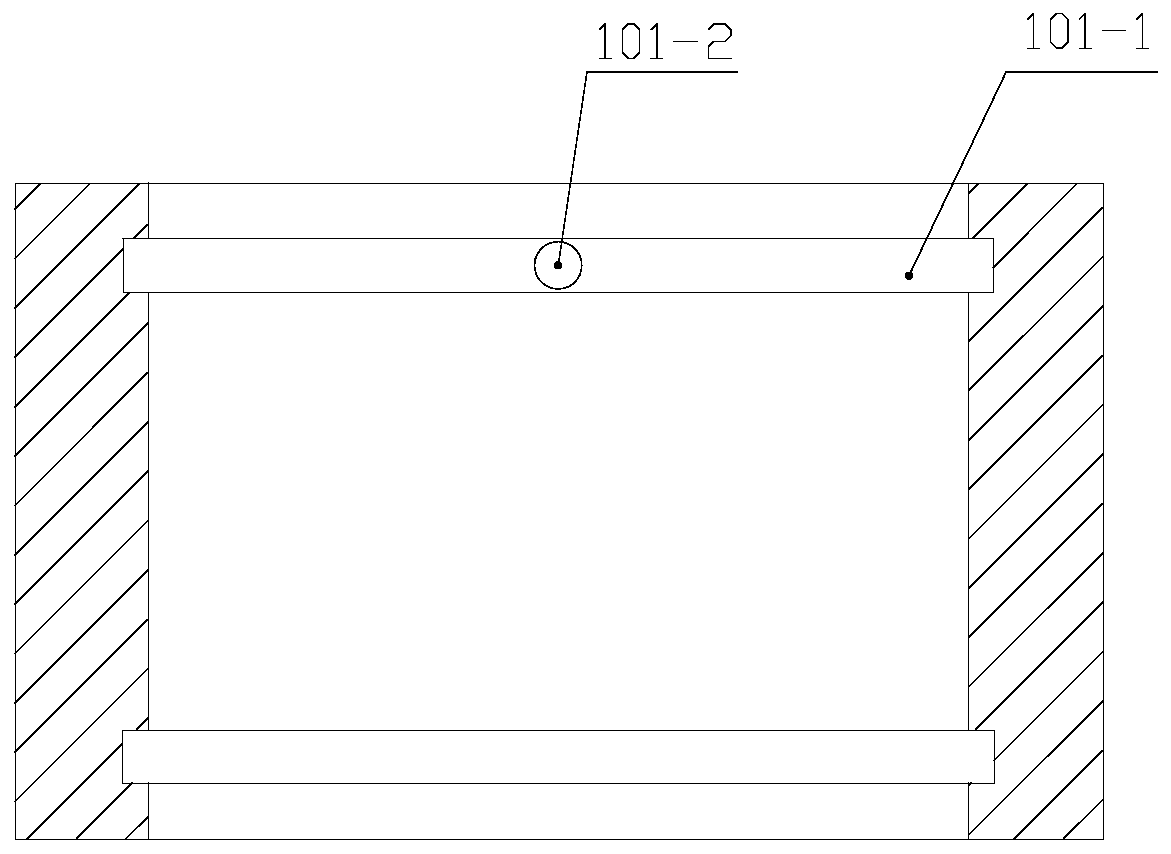

[0028] Specific implementation mode one: combine Figure 1~4 Describe this embodiment, a special diffusion connection tool for copper and steel, which includes an expansion core 1 and several expansion petals 2, wherein the expansion core 1 is a columnar structure and its outer circular surface is a conical surface, and several expansion petals 2 are wrapped around a copper ring 100 The central axis of the copper ring 100 is arranged in the copper ring 100 and each expansion valve 2 is in contact with the inner wall of the copper ring 100 without gaps. The side of each expansion valve 2 away from the copper ring 100 is an inclined plane, and the expansion core 1 is inserted in several In the ring structure formed by the expansion petals 2, every two adjacent expansion petals 2 form a ring structure without gap contact, and the inner diameter of the small end of the ring structure is smaller than the outer diameter of the small end of the expansion core 1 It is set that the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com