Corrosion early warning monitor based on impedance conversion technology

A technology of early warning monitoring and impedance transformation, which is applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of low test accuracy of the impedance transformation circuit of the monitor, difficult sensor fabrication, and inconvenient replacement of test pieces, so as to improve the resistance to Effects of jamming capability, light weight, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

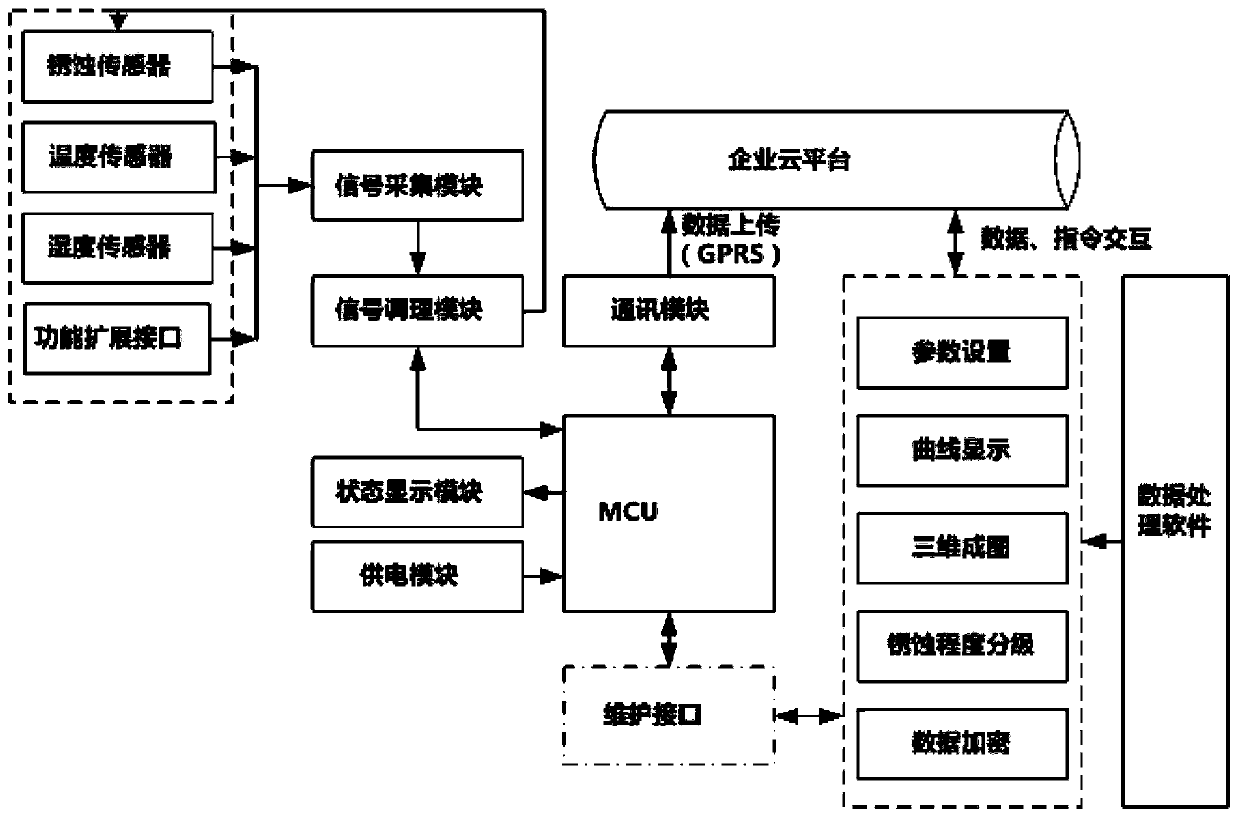

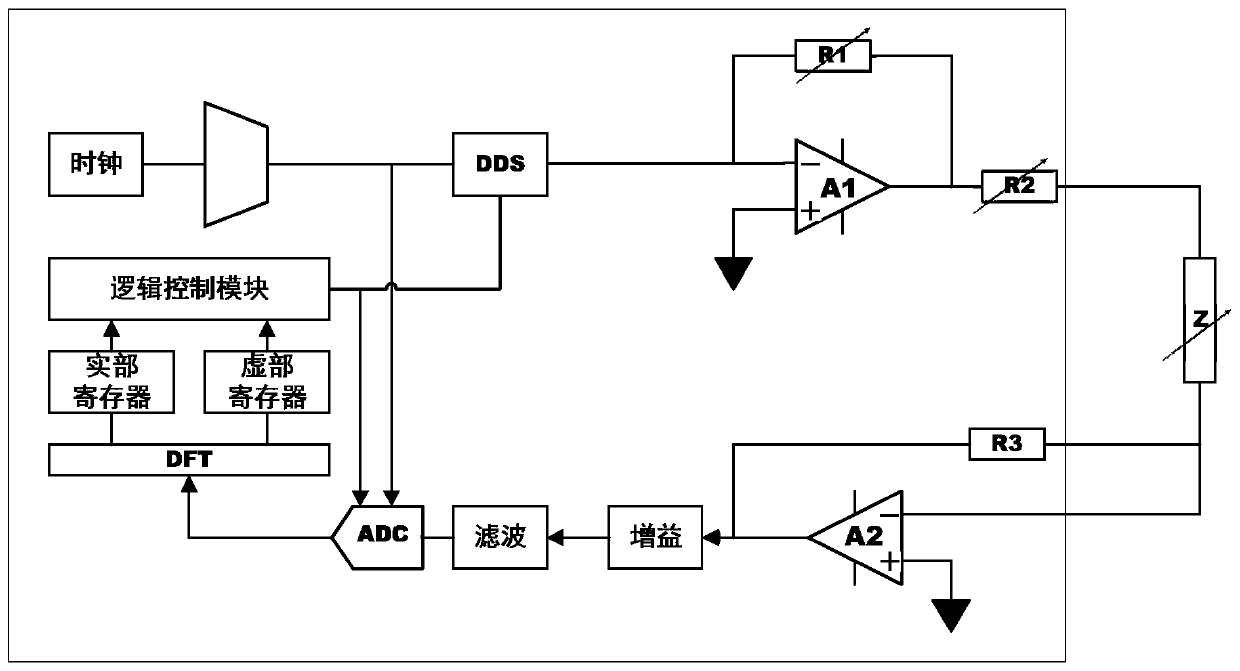

[0032] Such as figure 1 As shown, a corrosion early warning monitor based on impedance transformation technology of the present invention includes a corrosion sensor, a temperature / humidity sensor, a central processing unit, a signal acquisition module, a signal conditioning module, a status display module, a communication module and a power supply module. Among them, the central processing unit is connected to the signal acquisition module through the signal conditioning module, and the lead wire of the signal conditioning module applies an AC signal to the corrosion sensor. The input terminal of the signal acquisition module is connected with a corrosion sensor and a temperature / humidity sensor. The analog-to-digital converter (ADC) in the conditioning module processes the conversion and enters the central processing unit.

[0033] The central pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com