Boiler device with anti-scaling function

A boiler device and anti-fouling technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of water softening, increase boiler energy consumption, affect boiler heat transfer efficiency, etc., and achieve easy installation and Effects of dismantling operations, reducing energy consumption, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

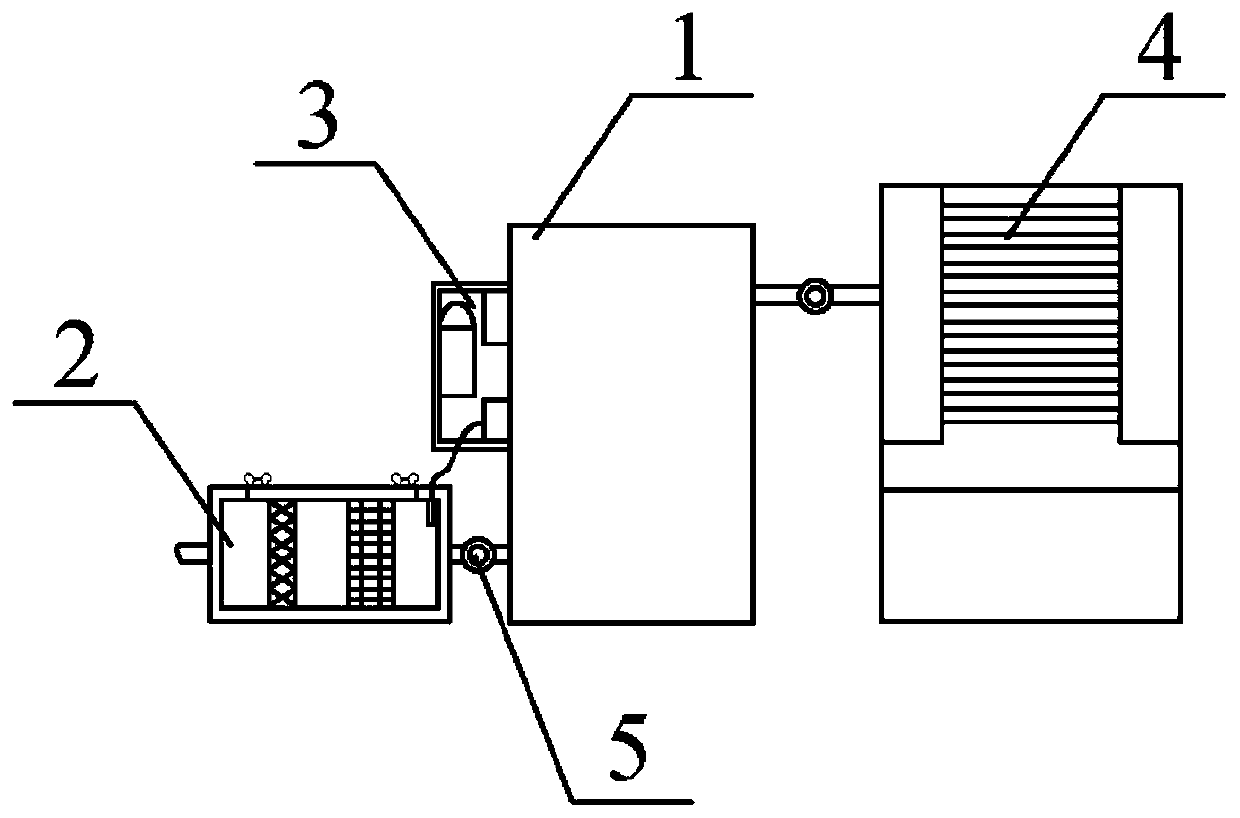

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: a boiler device with anti-scaling function, including a water storage tank, a softening component, a detection component, a boiler body and a booster pump, and the softening component is fixed to the water storage tank by bolts the left side of the water storage tank, and the softening component is connected to the water storage tank through pipes; the detection component is fixed above the left side of the water storage tank by bolts; the boiler body is fixed on the right side of the water storage tank by bolts, and the upper end of the boiler body It is connected to the water storage tank through a pipeline; two booster pumps are used, and the booster pump is fixed on the pipeline between the water storage tank, the softening component and the boiler body through bolts, and the booster pump is connected to the mains through a wire. Among them, the booster pump is LY-JLM type.

Embodiment 2

[0025] A boiler device with anti-scaling function, including a water storage tank, a softening component, a detection component, a boiler body and a booster pump. The softening component is fixed on the left side of the water storage tank by bolts, and the softening component is connected to the storage The water tank is connected; the detection assembly is fixed above the left side of the water storage tank by bolts; the boiler body is fixed on the right side of the water storage tank by bolts, and the upper end of the boiler body is connected with the water storage tank through pipes; Two pressure pumps are used, and the booster pump is fixed on the pipeline between the water storage tank, the softening component and the boiler body through bolts. The booster pump is connected to the mains through wires, and the booster pump is LY-JLM type.

[0026] Preferably, the softening assembly includes a softening box, a water inlet, a water outlet, a cover plate, a filter screen, a so...

Embodiment 3

[0029] A boiler device with anti-scaling function, including a water storage tank, a softening component, a detection component, a boiler body and a booster pump. The softening component is fixed on the left side of the water storage tank by bolts, and the softening component is connected to the storage The water tank is connected; the detection assembly is fixed above the left side of the water storage tank by bolts; the boiler body is fixed on the right side of the water storage tank by bolts, and the upper end of the boiler body is connected with the water storage tank through pipes; Two pressure pumps are used, and the booster pump is fixed on the pipeline between the water storage tank, the softening component and the boiler body through bolts. The booster pump is connected to the mains through wires, and the booster pump is LY-JLM type.

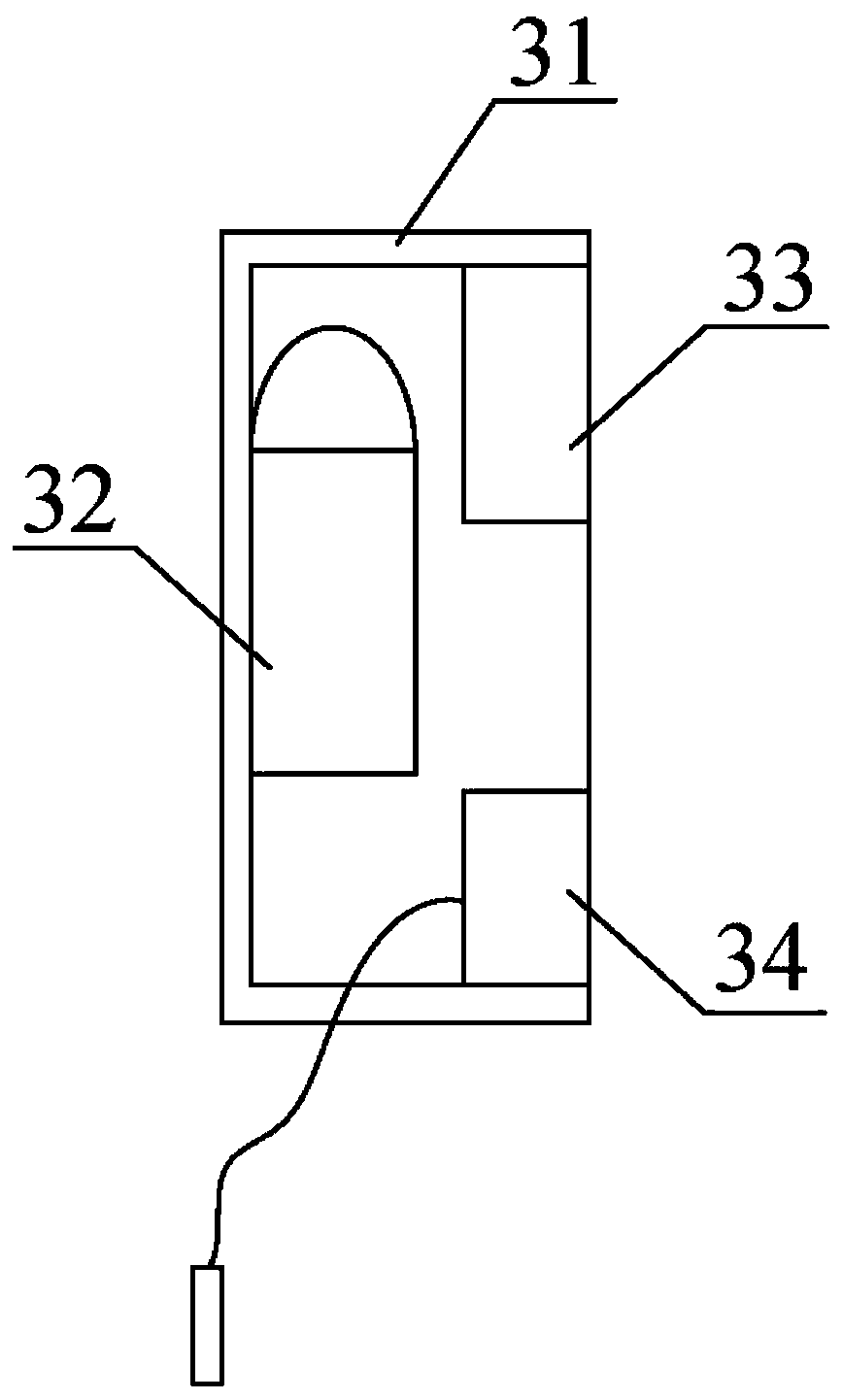

[0030] Preferably, the detection assembly includes a box body, a buzzer, a battery and an online hardness tester, the box body is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com