500Mpa grade tough weather-resistant bridge steel and preparation method thereof

A bridge steel, strong and tough technology, applied in the field of metallurgy, can solve the problem of less weather resistance research, achieve the effects of high stability, reduced use, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

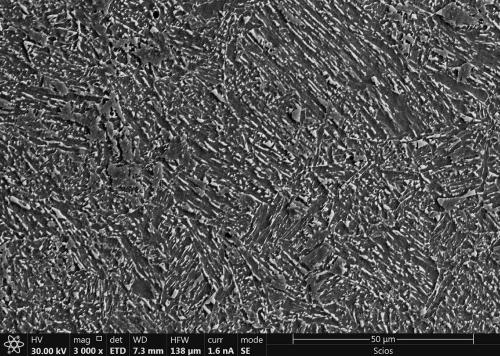

Image

Examples

Embodiment 1

[0046] Embodiment 1. Firstly, the molten iron is smelted. After the molten iron is pretreated by dephosphorization and desulfurization, it is kept at 1600° C. for 25 minutes in an electric arc furnace for smelting to obtain molten iron.

[0047] Then proceed as follows:

[0048] A. Refining: transfer the molten iron to the ladle furnace, press the pressure of 0.3 MPa and the flow rate of 140NL / min, blow Ar gas and stir, and refine for 45 minutes;

[0049] Adjust the mass percentage of chemical composition as follows: C 0.050, Si 0.33, Mn 1.27, Cr 0.45, Ni0.37, Cu 0.33, Mo 0.21, P 0.0085, S 0.0024, Nb 0.028, V 0.022, Ti 0.016, Al 0.026, The balance is Fe and unavoidable impurities, stirring for 20-30 minutes;

[0050] B. Vacuum treatment: transfer to the ladle refining furnace, control the vacuum degree to 0.8 mbar, keep the vacuum for 25 minutes, stir for 16 minutes after breaking the vacuum, adjust the chemical composition, feed Al wire, continuous casting electromagnetic st...

Embodiment 2

[0057] Embodiment 2: Firstly, the molten iron is smelted. After the molten iron is pretreated by dephosphorization and desulfurization, the molten iron is smelted under the control of 1600° C. for 25 minutes in an electric arc furnace to obtain molten iron.

[0058] Then proceed as follows:

[0059]A. Refining: transfer the molten iron to the ladle furnace, press the pressure of 0.4 MPa and the flow rate of 130NL / min, blow Ar gas and stir, and refine for 40 minutes;

[0060] Adjust the mass percentage of chemical composition by the numerical value of table 1, and surplus is Fe and unavoidable impurity,

[0061] Stir for 20-30 minutes;

[0062] B. Vacuum treatment: transfer to the ladle refining furnace, control the vacuum degree to 0.9 mbar, keep the vacuum for 20 minutes, stir for 18 minutes after breaking the vacuum, adjust the chemical composition, feed Al wire, continuous casting electromagnetic stirring, control the stirring intensity At 0.8L / (min•t), the stirring time ...

Embodiment 3

[0069] Embodiment 3: Firstly, molten iron is smelted. After the molten iron is pretreated by dephosphorization and desulfurization, the molten iron is smelted at 1600° C. for 25 minutes under control of an electric arc furnace to obtain molten iron.

[0070] Then proceed as follows:

[0071] A. Refining: transfer the molten iron to the ladle furnace, press the pressure of 0.2 MPa and the flow rate of 150NL / min, blow Ar gas and stir, and refine for 50 minutes;

[0072] Adjust the mass percentage of chemical composition by the numerical value of table 1, and surplus is Fe and unavoidable impurity,

[0073] Stir for 20-30 minutes;

[0074] B. Vacuum treatment: transfer to the ladle refining furnace, control the vacuum degree to 0.7 mbar, keep the vacuum for 23 minutes, stir for 16 minutes after breaking the vacuum, adjust the chemical composition, feed Al wire, and continuously cast electromagnetic stirring to control the stirring intensity At 0.8L / (min•t), the stirring time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com