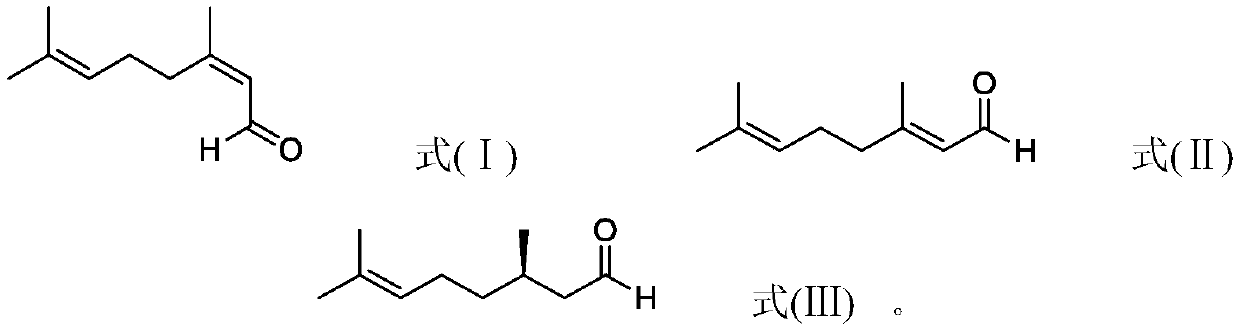

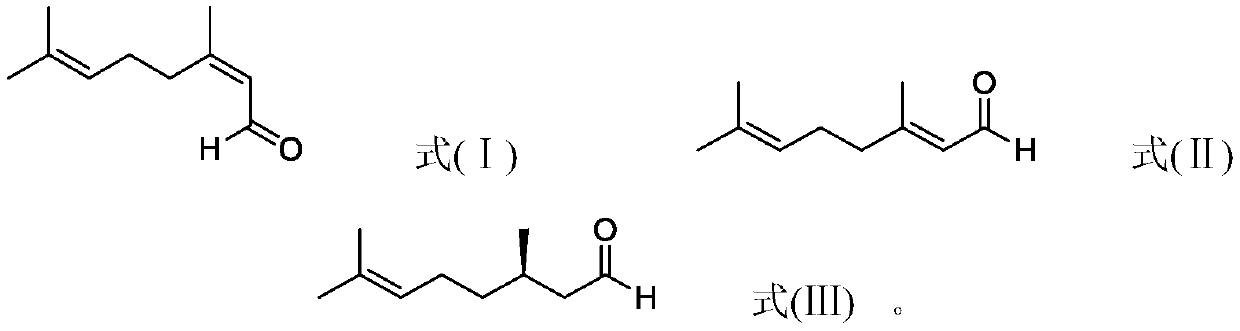

Method for preparing optically active citronellal and catalyst system for method

An optically active, citronellal technology, applied in the direction of physical/chemical process catalysts, organic chemical methods, chemical instruments and methods, etc., can solve the problems that cannot be directly satisfied, and the optical selectivity is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

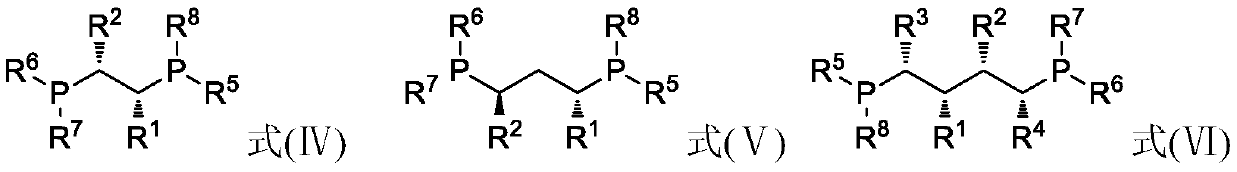

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 (loaded TiO 2 Preparation of activated carbon)

[0062] Weigh 5 g of activated carbon, wash it three times with distilled water, dehydrate it in a vacuum oven at a constant temperature of 100° C. for 12 hours, and set aside. Take 24 mL of absolute ethanol, add a small amount of nitric acid dropwise to adjust the pH to 3.5, measure 3 mL of tetra-n-butyl titanate, and drop it into the absolute ethanol solution while stirring. Add the above 5g of 10-20 mesh activated carbon into the above system, stir vigorously for 20min, measure 5mL of distilled water and 13mL of absolute ethanol respectively to make a mixed solution, control the titration rate to 30d / min, slowly drop into the reaction mixture under constant stirring In the system, the stirring was continued for 10 min and left to stand to obtain a black sol. The obtained gel was placed in a constant temperature drying oven at 600°C for 12 hours to slowly evaporate the absolute ethanol in the colloid. Aft...

Embodiment 2

[0063] Embodiment 2 (loaded TiO 2 Preparation of activated carbon)

[0064] Weigh 5 g of activated carbon, wash it three times with distilled water, dehydrate it in a vacuum oven at a constant temperature of 100° C. for 12 hours, and set aside. Take 24 mL of absolute ethanol, add a small amount of nitric acid dropwise to adjust the pH to 3.5, measure 6 mL of tetra-n-butyl titanate, and drop it into the absolute ethanol solution while stirring. Add the above 5g of 10-20 mesh activated carbon into the above system, stir vigorously for 20min, measure 5mL of distilled water and 13mL of absolute ethanol respectively to make a mixed solution, control the titration rate to 30d / min, and slowly drop into the reaction system under constant stirring , continue to stir for 10 min, and stand still to obtain a black sol. The obtained gel was placed in a constant temperature drying oven at 600°C for 12 hours to slowly evaporate the absolute ethanol in the colloid. After drying, it was gro...

Embodiment 3

[0065] Embodiment 3 (loaded TiO 2 Preparation of activated carbon)

[0066] Weigh 5 g of activated carbon, wash it three times with distilled water, dehydrate it in a vacuum oven at a constant temperature of 100° C. for 12 hours, and set aside. Take 24 mL of absolute ethanol, add a small amount of nitric acid dropwise to adjust the pH to 3.5, measure 6 mL of tetra-n-butyl titanate, and drop it into the absolute ethanol solution while stirring. Add the above 5g of 20-30 mesh activated carbon into the above system, stir vigorously for 20min, measure 5mL of distilled water and 13mL of absolute ethanol respectively to make a mixed solution, control the titration rate to 30d / min, and slowly drop into the reaction system under constant stirring , continue to stir for 10 min, and stand still to obtain a black sol. The obtained gel was placed in a constant temperature drying oven at 600°C for 12 hours to slowly evaporate the absolute ethanol in the colloid. After drying, grind it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com