Partition reaction system for preparing aromatic hydrocarbon by methanol conversion and reaction method thereof

A technology for methanol conversion and reaction system, which is applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, hydrocarbon production by condensation between hydrocarbons and non-hydrocarbons, etc. rate, good technical effect, the effect of promoting full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

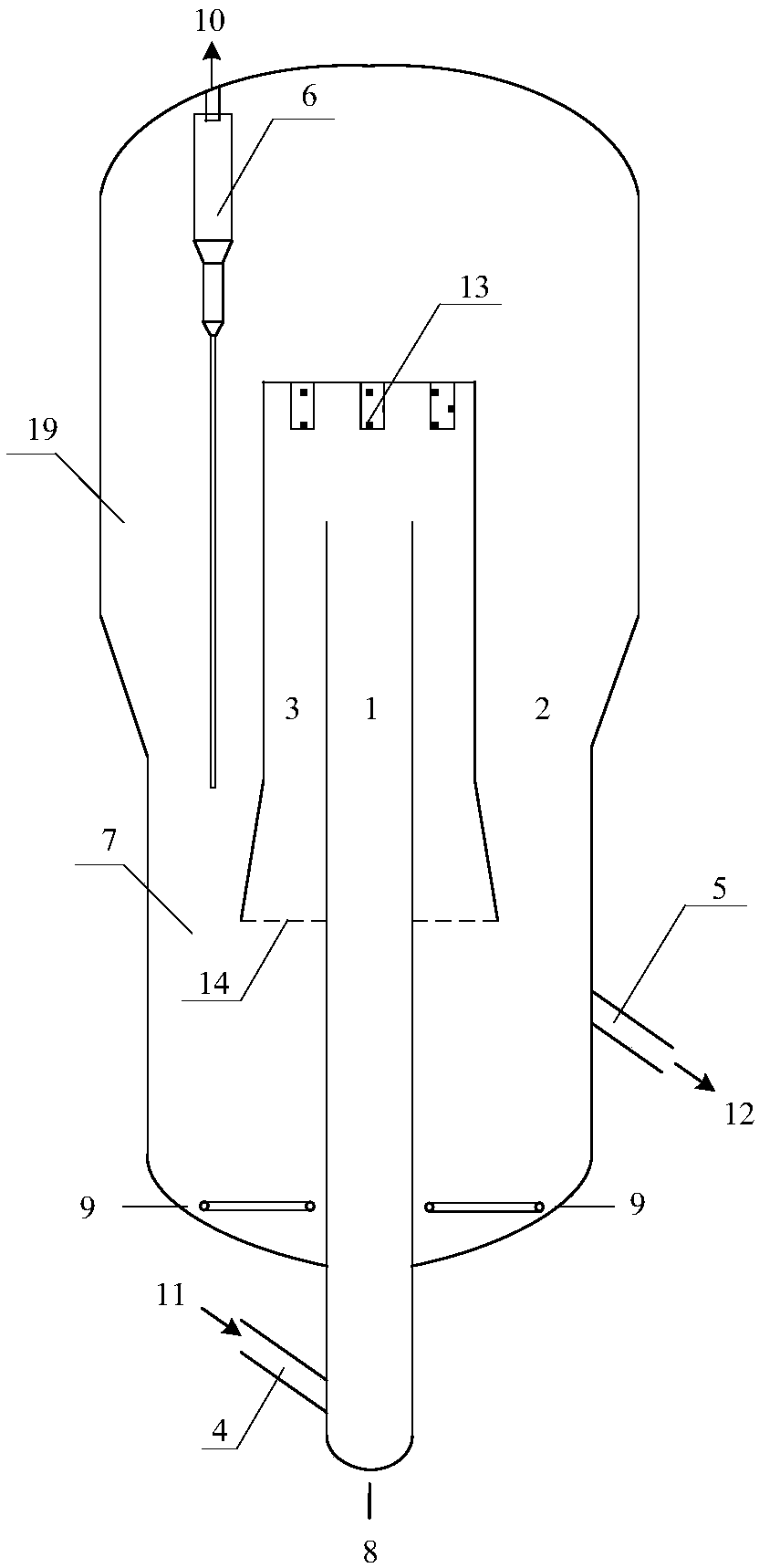

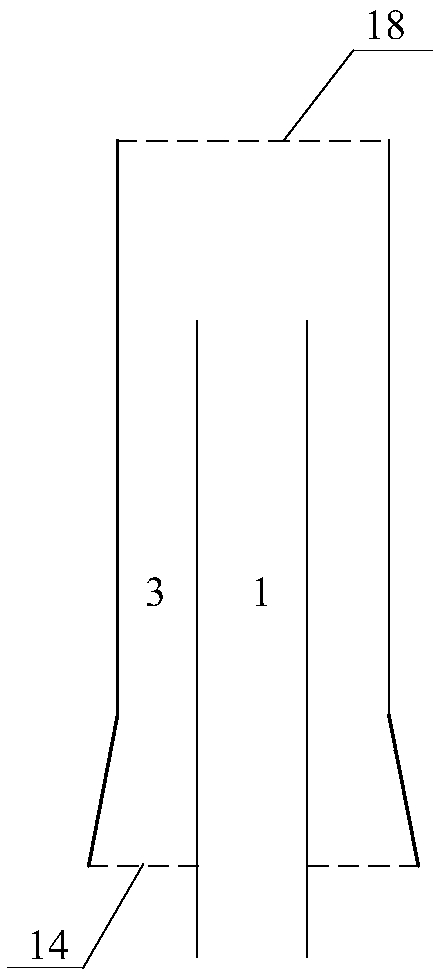

[0032] use as figure 1 Shown device, fluidized bed reactor (2) is fluidized bed reactor dense phase section (7) and fluidized bed reactor dilute phase section (19) from bottom to top; Light hydrocarbon reaction zone (1) and settling Zone (3) is coaxial with fluidized bed reactor (2); light hydrocarbon reaction zone (1) is divided into light hydrocarbon reaction zone lower part (15), light hydrocarbon reaction zone middle part (16), light hydrocarbon reaction zone from bottom to top The upper part (17) of the zone; the lower part (15) of the light hydrocarbon reaction zone is located under the fluidized bed reactor (2), the middle part (16) of the light hydrocarbon reaction zone is located in the fluidized bed reactor (2), and the upper part of the light hydrocarbon reaction zone (17) is located in the settling zone (3); the settling zone (3) is positioned at the inside of the fluidized bed reactor (2), the top of the settling zone (3) is provided with a filter (13), and the bo...

Embodiment 2

[0040] use as figure 1 Shown device, fluidized bed reactor (2) is fluidized bed reactor dense phase section (7) and fluidized bed reactor dilute phase section (19) from bottom to top; Light hydrocarbon reaction zone (1) and settling Zone (3) is coaxial with fluidized bed reactor (2); light hydrocarbon reaction zone (1) is divided into light hydrocarbon reaction zone lower part (15), light hydrocarbon reaction zone middle part (16), light hydrocarbon reaction zone from bottom to top The upper part (17) of the zone; the lower part (15) of the light hydrocarbon reaction zone is located under the fluidized bed reactor (2), the middle part (16) of the light hydrocarbon reaction zone is located in the fluidized bed reactor (2), and the upper part of the light hydrocarbon reaction zone (17) is located in the settling zone (3); the settling zone (3) is positioned at the inside of the fluidized bed reactor (2), the top of the settling zone (3) is provided with a filter (13), and the bo...

Embodiment 3

[0048] use as figure 1 Shown device, fluidized bed reactor (2) is fluidized bed reactor dense phase section (7) and fluidized bed reactor dilute phase section (19) from bottom to top; Light hydrocarbon reaction zone (1) and settling Zone (3) is coaxial with fluidized bed reactor (2); light hydrocarbon reaction zone (1) is divided into light hydrocarbon reaction zone lower part (15), light hydrocarbon reaction zone middle part (16), light hydrocarbon reaction zone from bottom to top The upper part (17) of the zone; the lower part (15) of the light hydrocarbon reaction zone is located under the fluidized bed reactor (2), the middle part (16) of the light hydrocarbon reaction zone is located in the fluidized bed reactor (2), and the upper part of the light hydrocarbon reaction zone (17) is located in the settling zone (3); the settling zone (3) is positioned at the inside of the fluidized bed reactor (2), the top of the settling zone (3) is provided with a filter (13), and the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com