Dust removal mechanism for sand box for lost foam casting

A lost foam casting and sand box technology, which is applied in casting molding equipment, molds, mechanical equipment, etc., can solve the problems of affecting cutting efficiency and quality, not being able to be fixed well, and adverse to human health, etc., and achieve a simple and convenient structure. The effect of cutting and preventing workpiece movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

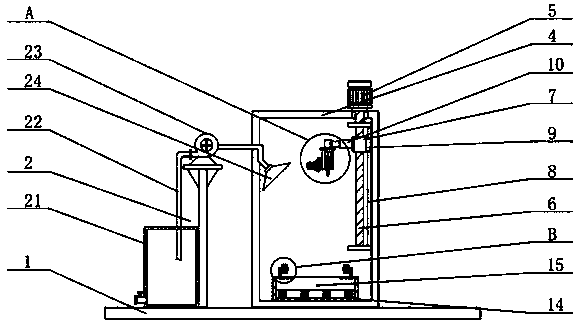

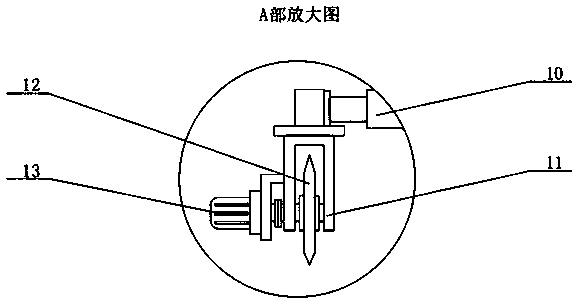

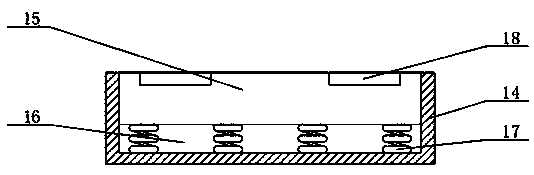

[0022] see Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: a sand box dust removal mechanism for lost foam casting, including a base 1, a support column 3 and a fixing frame 4, and a support column 3 is provided on one side of the upper surface of the base 1, One side of the support column 3 is provided with a dust removal mechanism 2, the fixed frame 4 is arranged in the middle of the upper end of the base 1, and the top side of the fixed frame 4 is equipped with a first motor 5, and the output end of the first motor 5 runs through the top of the fixed frame 4 A threaded mandrel 6 is fixedly connected to the inside of the fixed frame 4, and a screw sleeve 7 is provided on the threaded sleeve on the screw mandrel 6. A chute 8 is arranged on the inner wall of the fixed frame 4 near the side of the screw mandrel 6, and the threaded sleeve 7 is close to the chute 8. One side of the sliding block 9 is connected with a slide block 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com