Chilled-mirror dew-point hygrometer capable of quickly measuring extremely low dew point

A dew point meter, extremely low technology, applied in the field of dew point temperature measurement, can solve the problems of inability to reduce the mirror surface temperature to extremely low, the limitation of extremely low dew point measurement, and slow measurement speed, so as to facilitate cleaning and maintenance, and improve the response time. Long, smooth gas flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

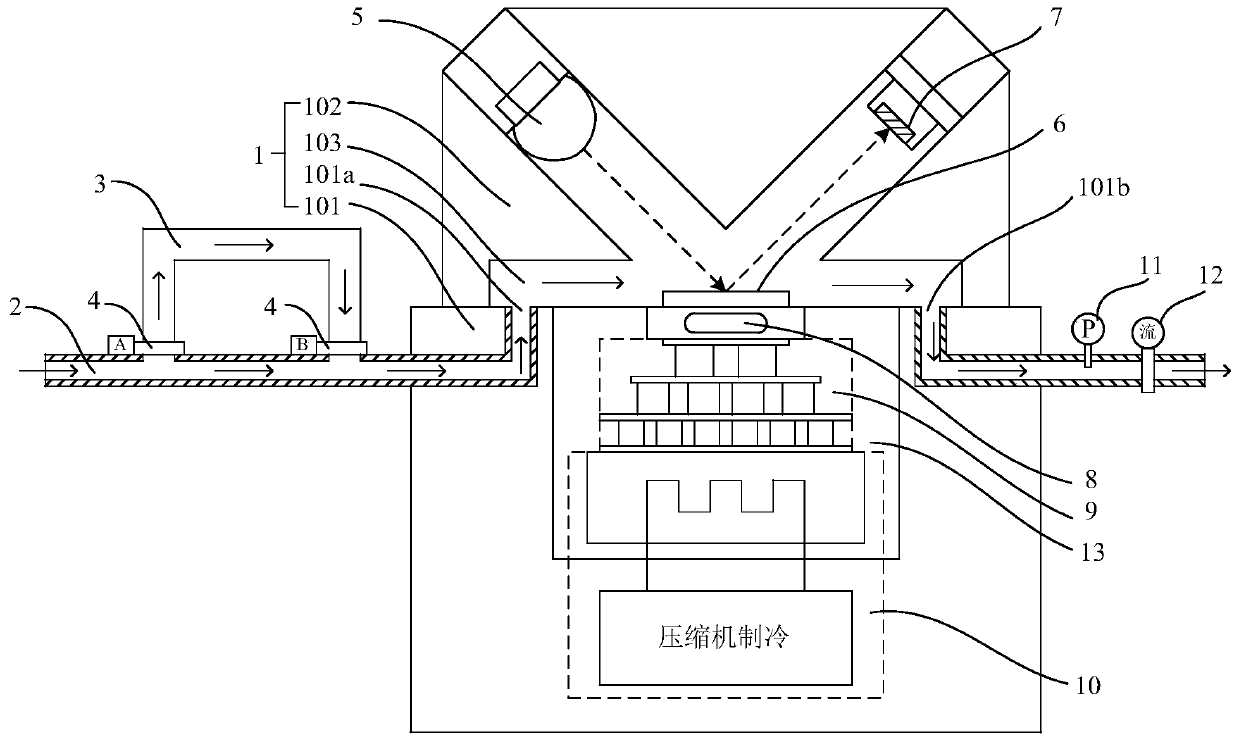

[0031] Please refer to Figure 1 to Figure 5 , the present invention is a chilled mirror dew point meter capable of rapidly measuring extremely low dew points, which includes a gas path system, an optical path system, a refrigeration system and a control system;

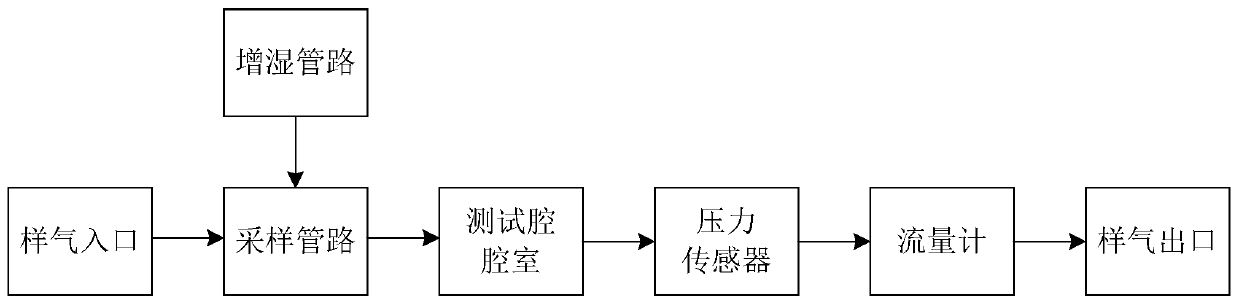

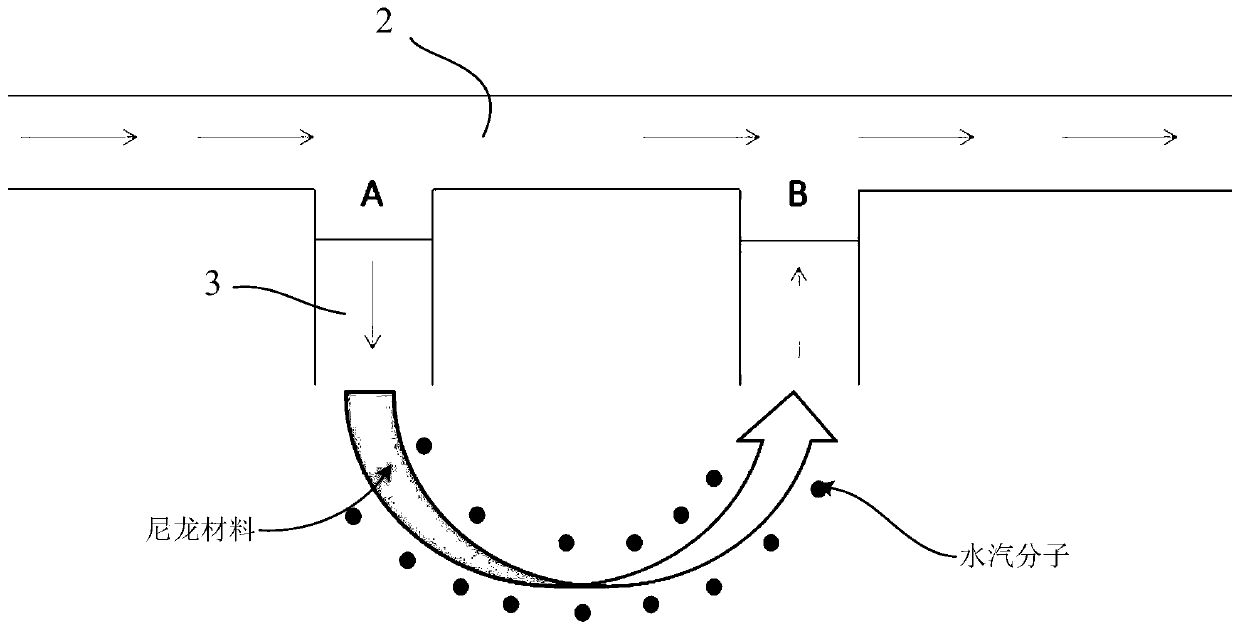

[0032]The gas circuit system includes a test chamber 1, a sampling pipeline 2 and an auxiliary humidification unit. The test chamber 1 includes an air inlet 101a and an air outlet 101b. The sampling pipeline 2 is connected to the air inlet 101a. The side wall of the sampling pipeline 2 is axially There are two openings in sequence. The auxiliary humidification unit includes a humidification pipeline 3 and a solenoid valve 4. Between the opening of the sampling line 2 and the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com