Optical fiber acoustic vibration sensor based on gold-plated vibration film and manufacturing method thereof

A vibrating film and sensor technology, applied in instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., to improve the quality of interference signals, improve reflectivity, and improve detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

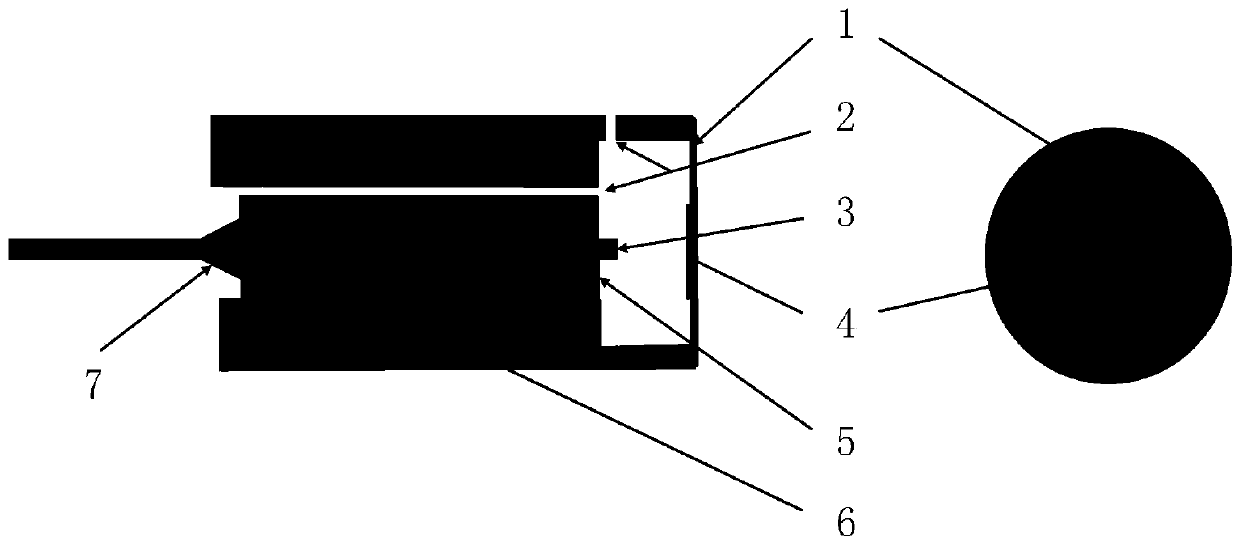

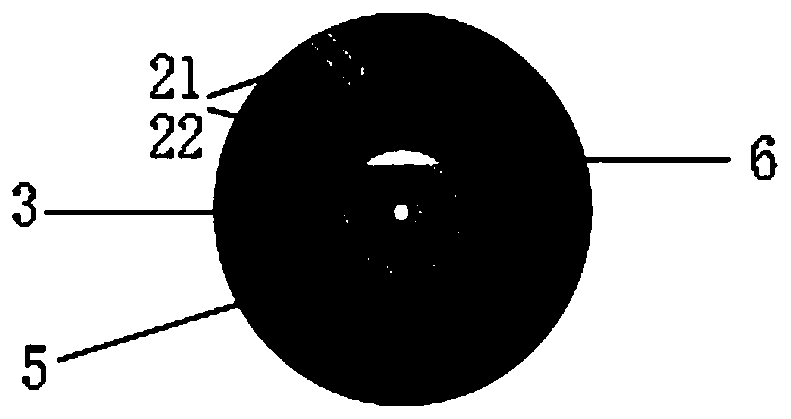

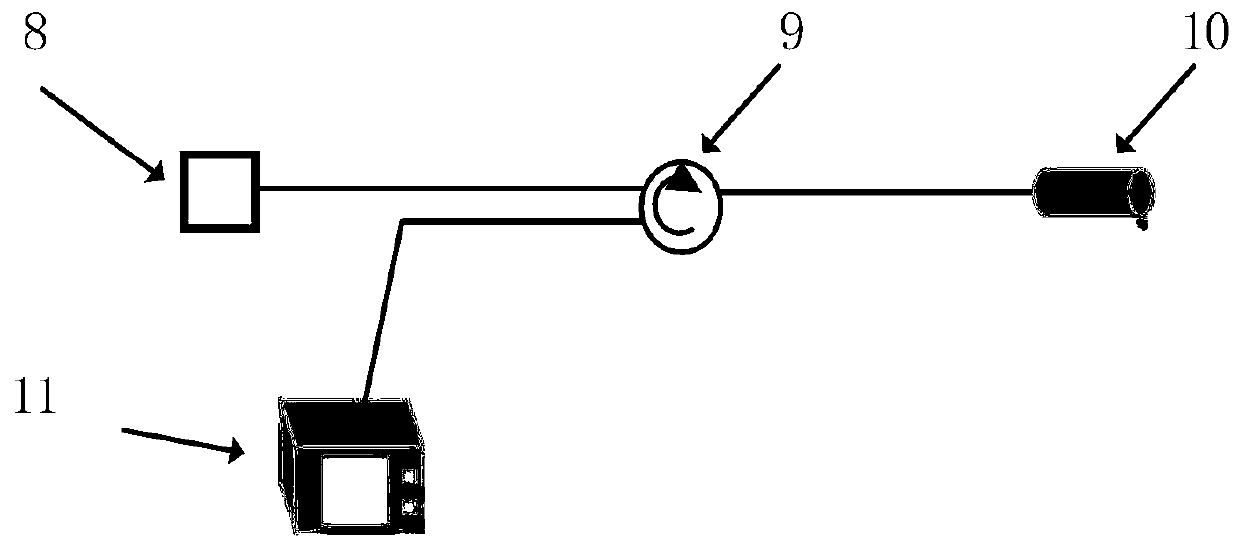

[0029] Such as image 3 Shown is a schematic diagram of an embodiment of the demodulation system of the fiber optic acoustic vibration sensor based on the gold-plated vibration film of the present invention. The system is used to realize the cavity length demodulation of the fiber optic acoustic vibration sensor. The specific process is: a broadband light source 8 with a central wavelength of 1550nm, the emitted light enters the optical fiber acoustic vibration sensor 10 through the optical fiber circulator 9, and is reflected by the end face of a single-mode optical fiber containing a tantalum pentoxide coating on the end surface and reflected by a gold-coated diaphragm. The interference occurs and enters the demodulation device 11 through the optical fiber circulator 10 through the transmission optical fiber. In the demodulation device, the cavity length information of the optical fiber acoustic vibration sensor can be obtained by using the relevant demodulation device, low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com