Air treatment system for biological laboratory

An air treatment system and laboratory technology, applied in the field of air treatment systems, can solve problems such as unfavorable toxic gas discharge and air pollution, and achieve the effects of preventing harmful gas deposition, promoting air circulation, and reducing wind speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

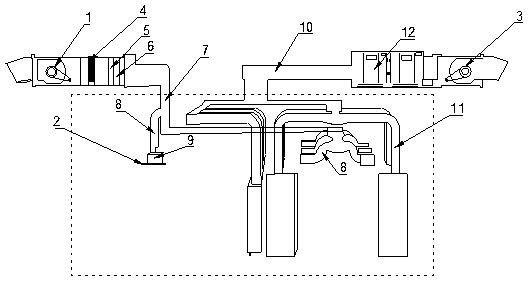

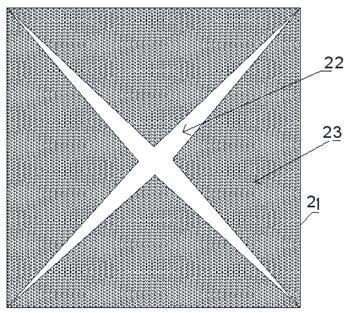

[0030] Such as Figure 1-5 As shown, this embodiment claims to protect a biological laboratory air treatment system, including a fresh air unit 1, a fresh air pipe group, a fresh air distribution device 2, an exhaust pipe group, an exhaust fan unit 3 and a flow guide device. A surface cooler 4, a primary filter 5 and a medium-efficiency filter 6 are sequentially arranged between the unit 1 and the fresh air pipe group. The fresh air pipe group includes a main fresh air pipe 7 and secondary fresh air pipes 8 at various levels. The end of the fresh air pipe 8 is connected to the fresh air distribution box 9, the end of the fresh air distribution box 9 is connected to the fresh air distribution device 8, and the exhaust pipe group includes the main exhaust pipe 10 and various levels of exhaust pipes. Pipe 11, the exhaust pipe at the end is connected to the flow guide device, and the main exhaust pipe 10 is connected to the exhaust gas treatment device 12 and then connected to the...

Embodiment 2

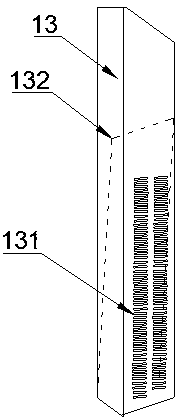

[0038] In this embodiment, the technical features that are the same as those in the above-mentioned embodiment will not be described in detail. The embodiments different from the above in this embodiment are as follows: the vertical flow guide device 13 is in the shape of a cuboid, and the flow guide device faces the side of the laboratory An air outlet is provided, and the air outlet 131 is in the shape of a horizontal strip, and the inside of the vertical deflector 13 is provided with a windshield 132 .

[0039] Preferably: the included angle between the wind deflector 132 and the horizontal direction is 15-45°.

[0040] The surface cooler used in the present invention, primary effect filter, intermediate effect filter are all commercially available products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com