Airflow fiber laying and covering device

A fiber and laying technology, which is applied in the field of air-flow laying fiber device, can solve the problems of fiber agglomeration, agglomeration, poor coating and hanging performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

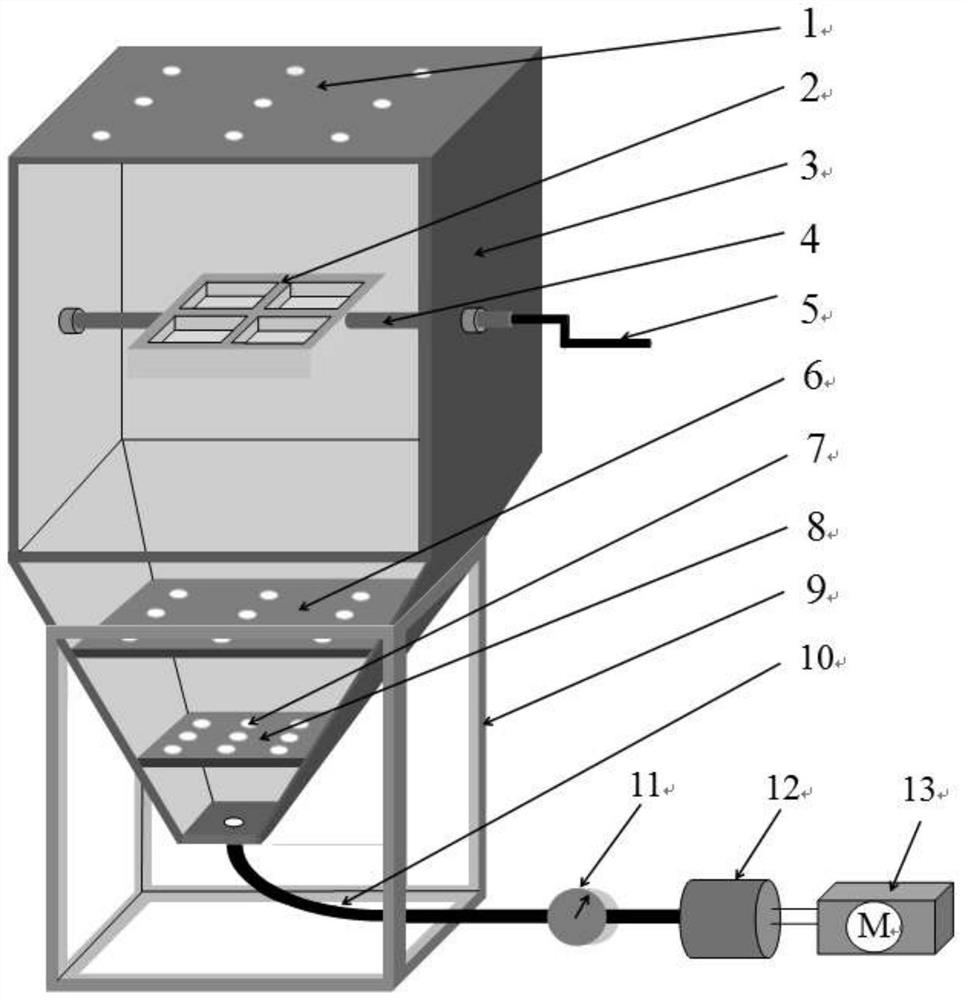

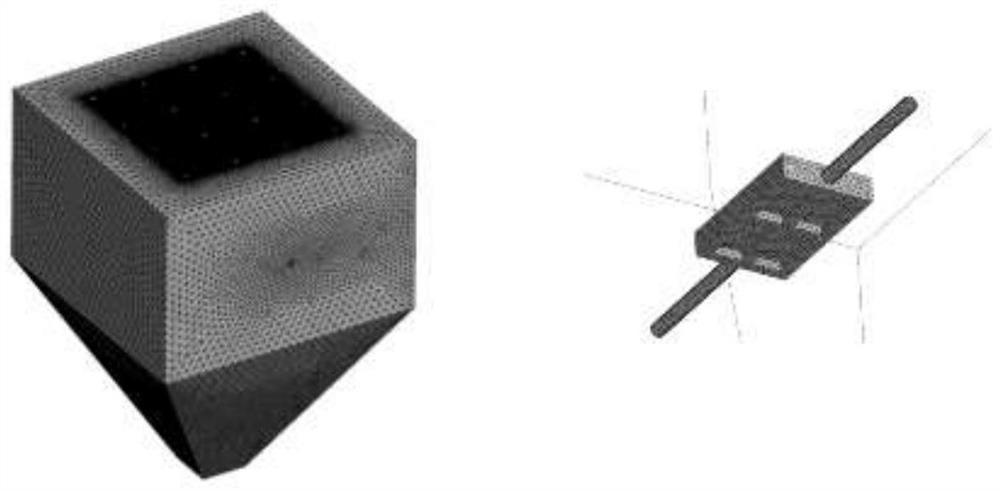

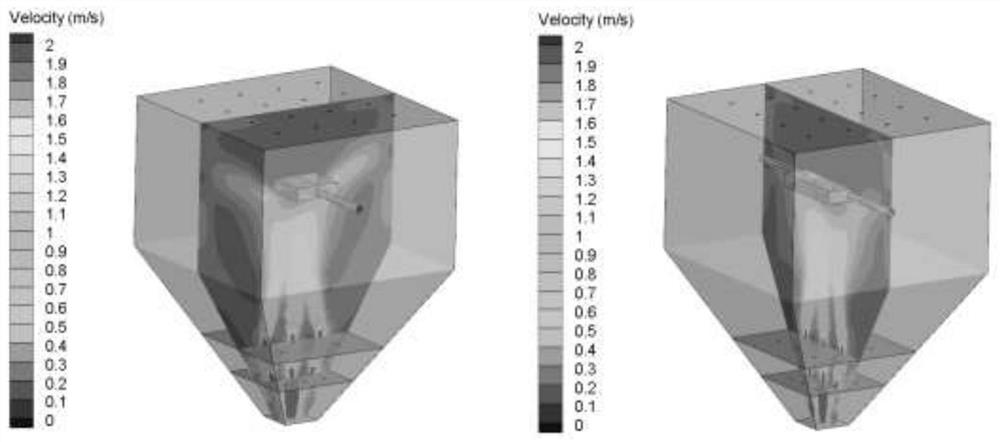

[0071] 1. Analysis of the mathematical model of the prior art air-laid fiber device

[0072] For the prior art ( figure 1 ) shows the analysis of the air-flow fiber-laying device, it is found that the fiber-laying time is prolonged, and the fiber will sink to each wall of the device, and no longer do the suspension movement. The occurrence of this phenomenon is directly related to the air distribution, fiber stress and device structure. The force of the fiber in the airflow is more complicated, including the force of the flow field on the fiber, the gravity of the fiber, the force between the fibers, etc., among which the force of the flow field on the fiber has the greatest influence on the movement state of the fiber. In order to prolong the suspension time of the fiber in the device, increase the probability of the fiber touching the surface of the shell, and increase the percentage of the fiber covering the shell, it is necessary to analyze the movement state and distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com