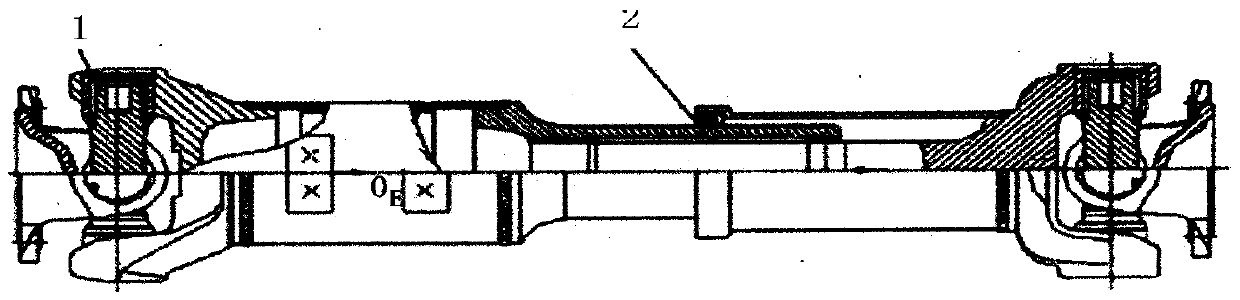

Equidistant molded surface transmission shaft

A transmission shaft and equidistant technology, applied in the field of transmission shaft, can solve the problems of difficult grinding and smoothing, symmetry, low engagement rate of spline tooth surface, large matching clearance and other problems of blank parts, so as to achieve stable, safe, reliable and dynamic operation. Balance accuracy No vibration, high dynamic balance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

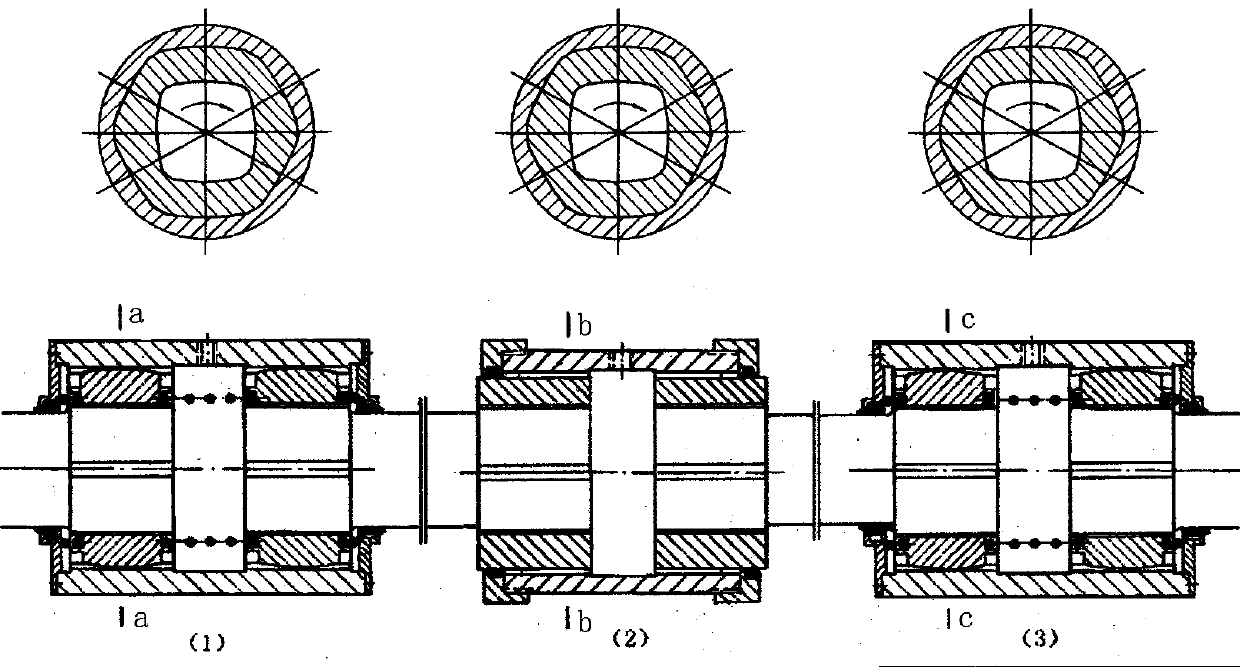

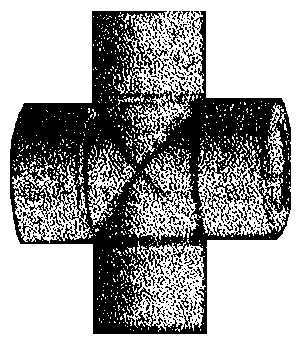

[0015] Milling or grinding equidistant large arc surface with "equal distance arc face processing machine tool". When working, the rotation of the large disc drives the workpiece to rotate, and a large arc surface is milled out with a high-speed milling cutter, and then the second large arc surface is milled with a small indexing plate, and all the large arc surfaces are milled in this cycle. out. For quenched equidistant arc faces, replace the milling cutter with a grinding wheel, and use a high-speed grinding wheel to grind each equidistant large arc surface.

[0016] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the patent scope of the present invention. Other equivalent changes using the spirit of the patent of the present invention all belong to the patent scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com