Long telescoping cardan shaft

A universal joint shaft, long telescopic technology, applied in the direction of coupling, elastic coupling, gear transmission mechanism, etc., can solve the problems of insufficient telescopic amount of SWP type universal shaft, poor dynamic balance of long telescopic amount, etc., to avoid The effect of hidden quality problems, stable transmission strength and good overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the embodiment of technical scheme of the present invention is described in detail:

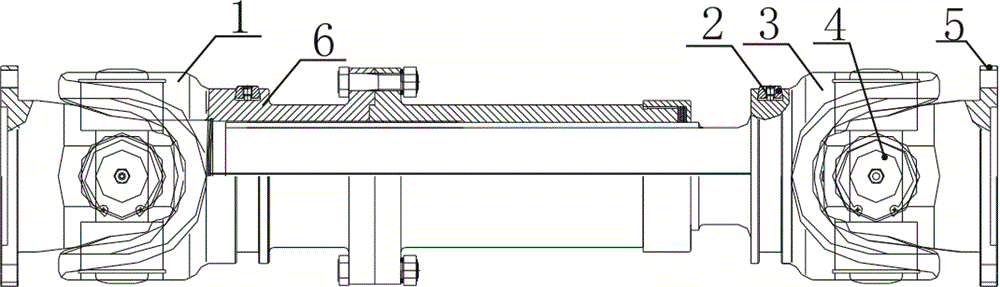

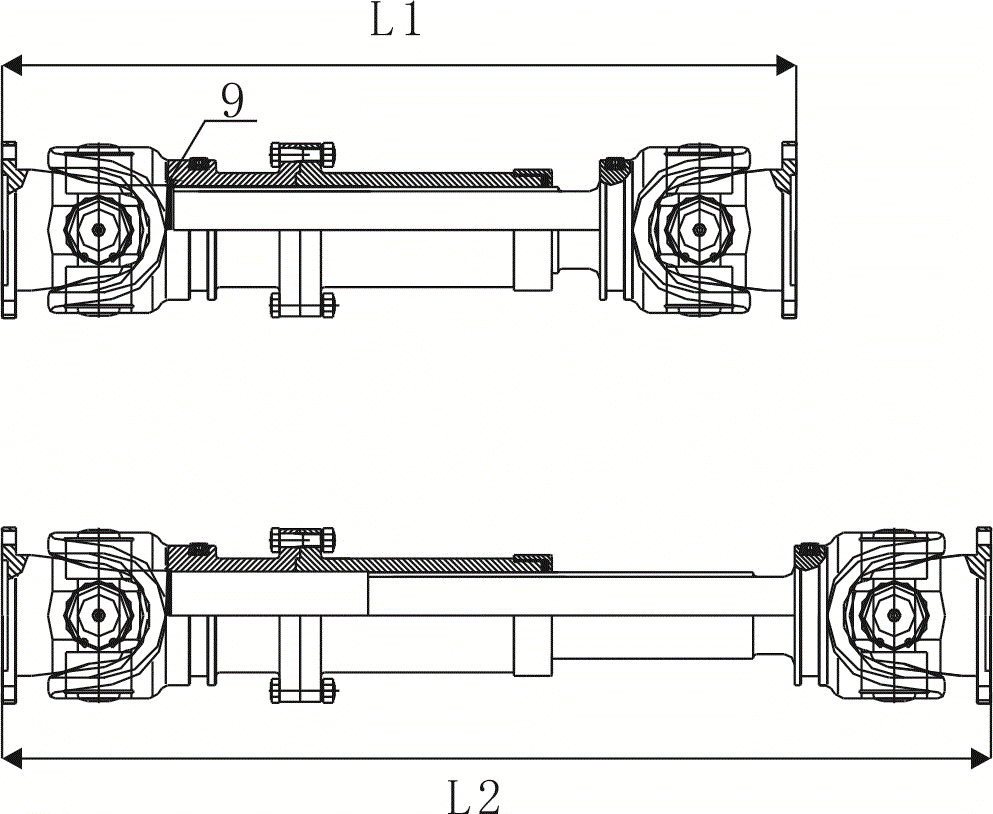

[0032] According to an embodiment of the present application, such as figure 1 As shown, the long telescopic cardan shaft provided by this solution includes a spline set 1, a spline shaft 3 and a spline 8 set in the spline set 1, and a spline set on the spline set 1 and the spline The balance groove 6 on the shaft 3; the spline 8 is also sleeved outside the spline shaft 3; the spline set 1 includes a spline sleeve 7, and a fork that is connected to the spline sleeve 7 through a seam positioning connection Head 10.

[0033] Both the spline shaft 3 and the spline sleeve 7 are connected with the upper cross shaft of the cross pack 4, and the upper cross shaft of the cross pack 4 is also connected with the flange 5 to play the role of connection and fixation.

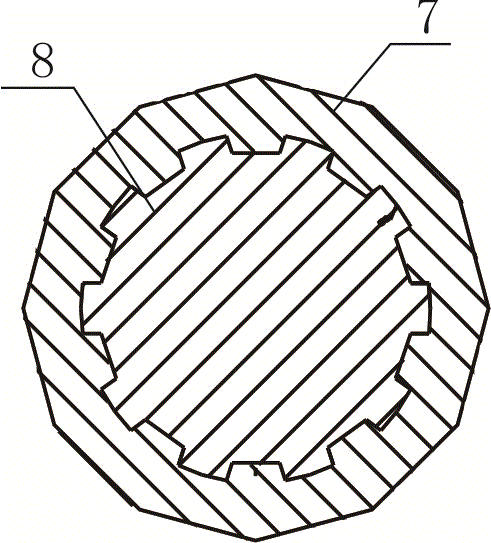

[0034] Such as Figure 4 As shown, the spline sleeve 7 and the fork head 10 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com