Variable cycle engine

A technology of variable cycle engines and combustion chambers, which is applied in the direction of machines/engines, ramjet engines, mechanical equipment, etc. It can solve the problems of airflow blockage in the turbine chamber, decrease in compressor power, and increase in wind resistance, so as to reduce parts and weight, Increase ceiling and top speed, avoid surge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in detail below through specific examples.

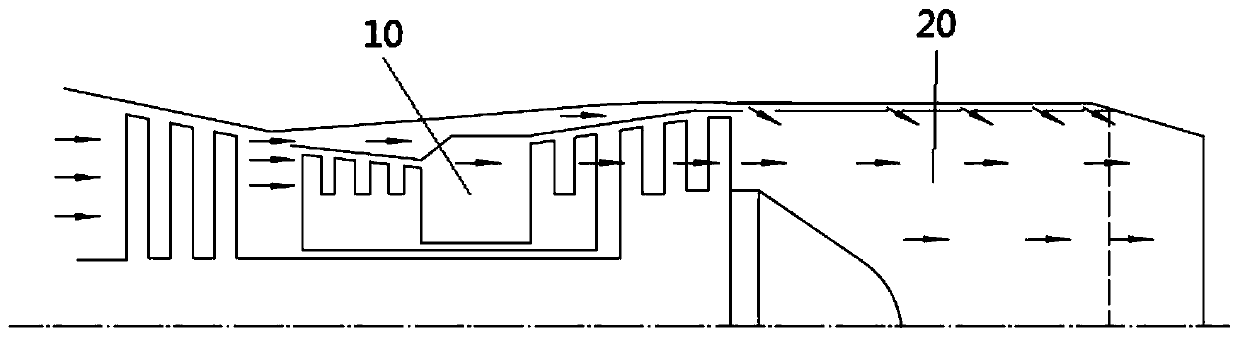

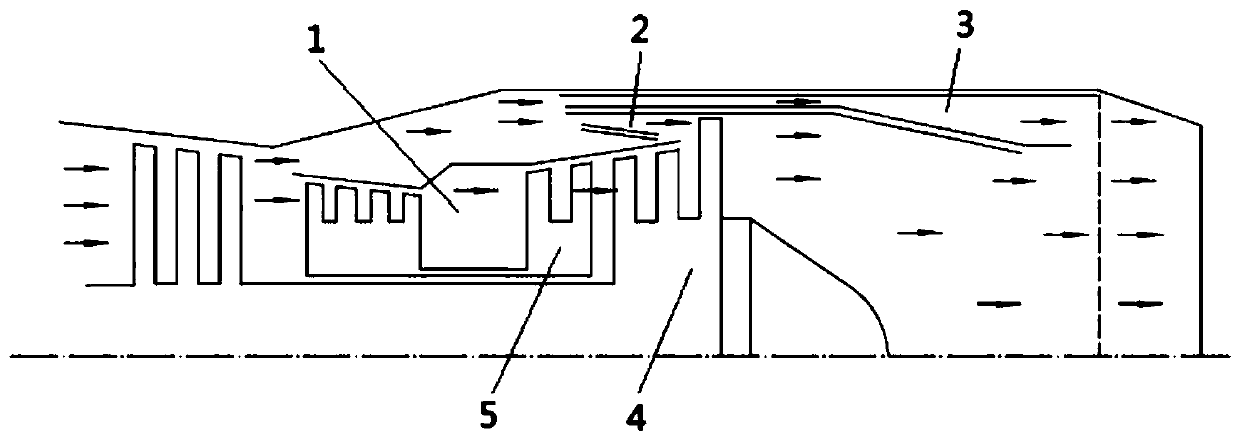

[0015] Such as figure 2 As shown, the variable cycle engine includes a first combustion chamber 1, a second combustion chamber 2 and a third combustion chamber 3 which are independent respectively, the first combustion chamber 1 is a core combustion chamber, and the second combustion chamber 2 is located outside the high-pressure turbine 5, The thermally expanded airflow combusted in the second combustion chamber 2 flows through the blade with the largest outer diameter at the rear end of the low-pressure turbine 4 , and the third combustion chamber 3 is located outside the second combustion chamber 2 and adopts a scram combustion chamber. The first combustion chamber 1, the second combustion chamber 2 and the third combustion chamber 3 adopt low-pressure evaporator auxiliary combustion (the evaporator is not shown in the figure), by adjusting the first combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com