Apparatus and method for monitoring compressor clearance and controlling a gas turbine

A technology for gas turbines and compressors, which is applied to gas turbine devices, jet propulsion devices, pump control, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

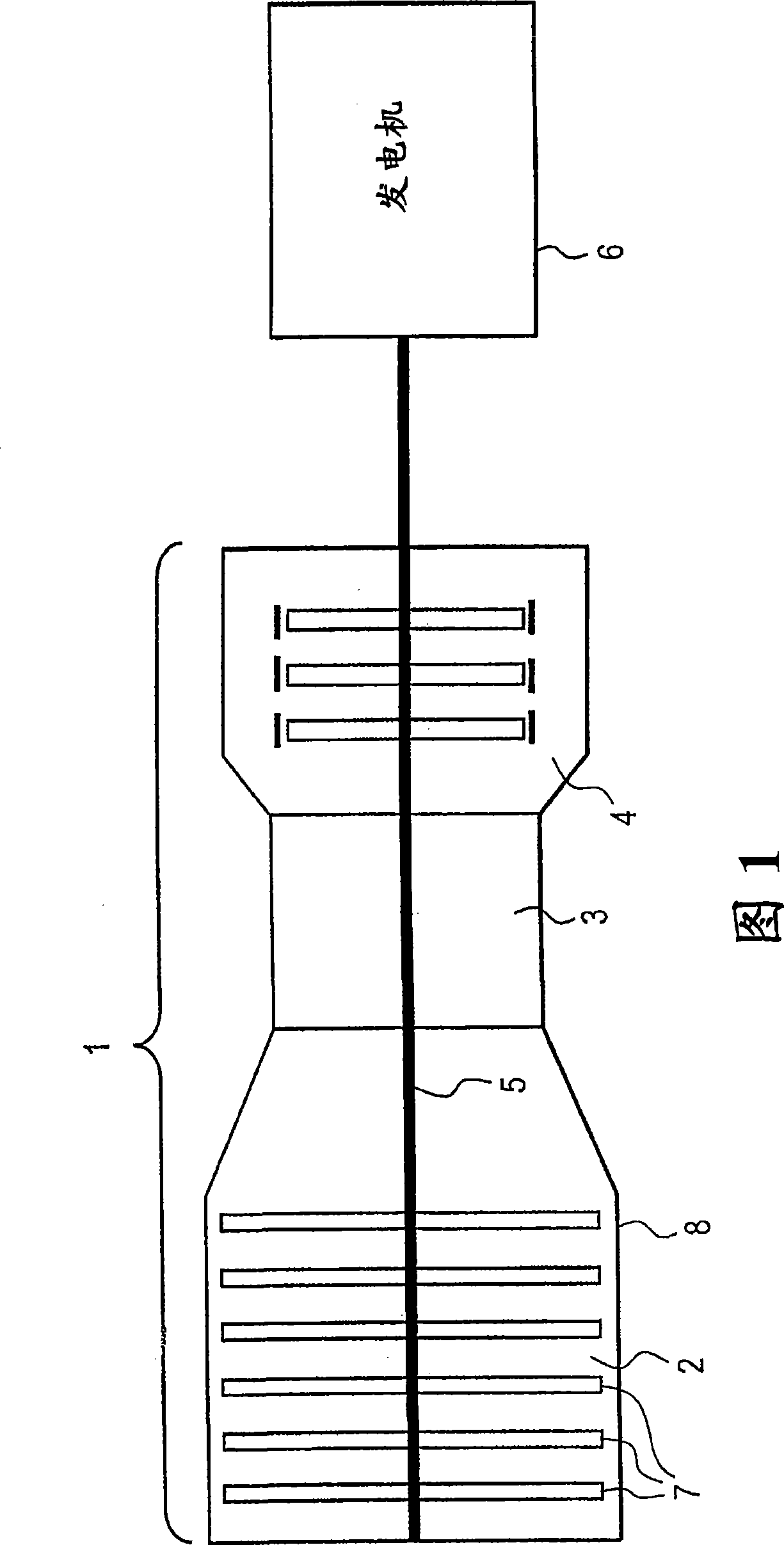

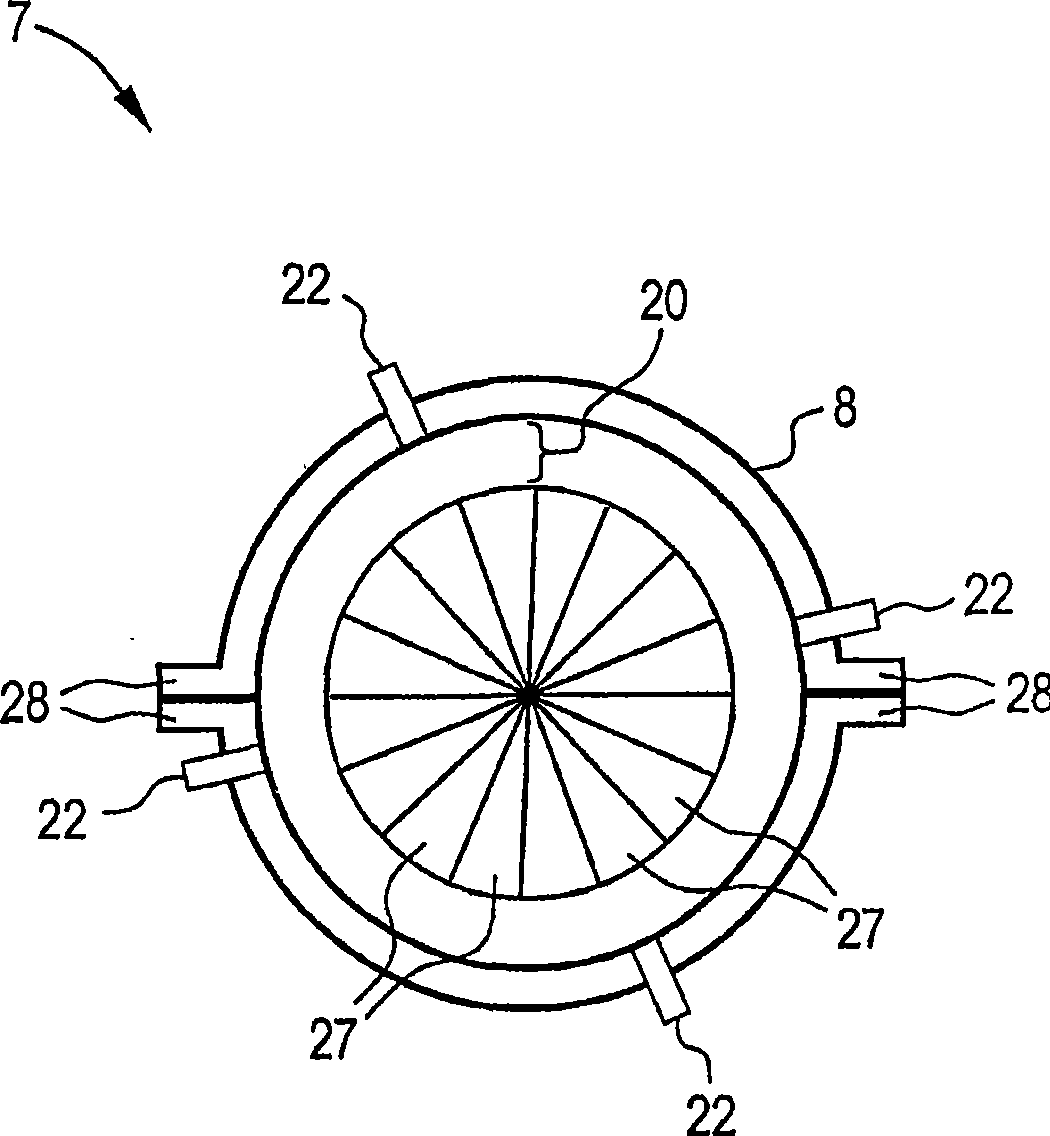

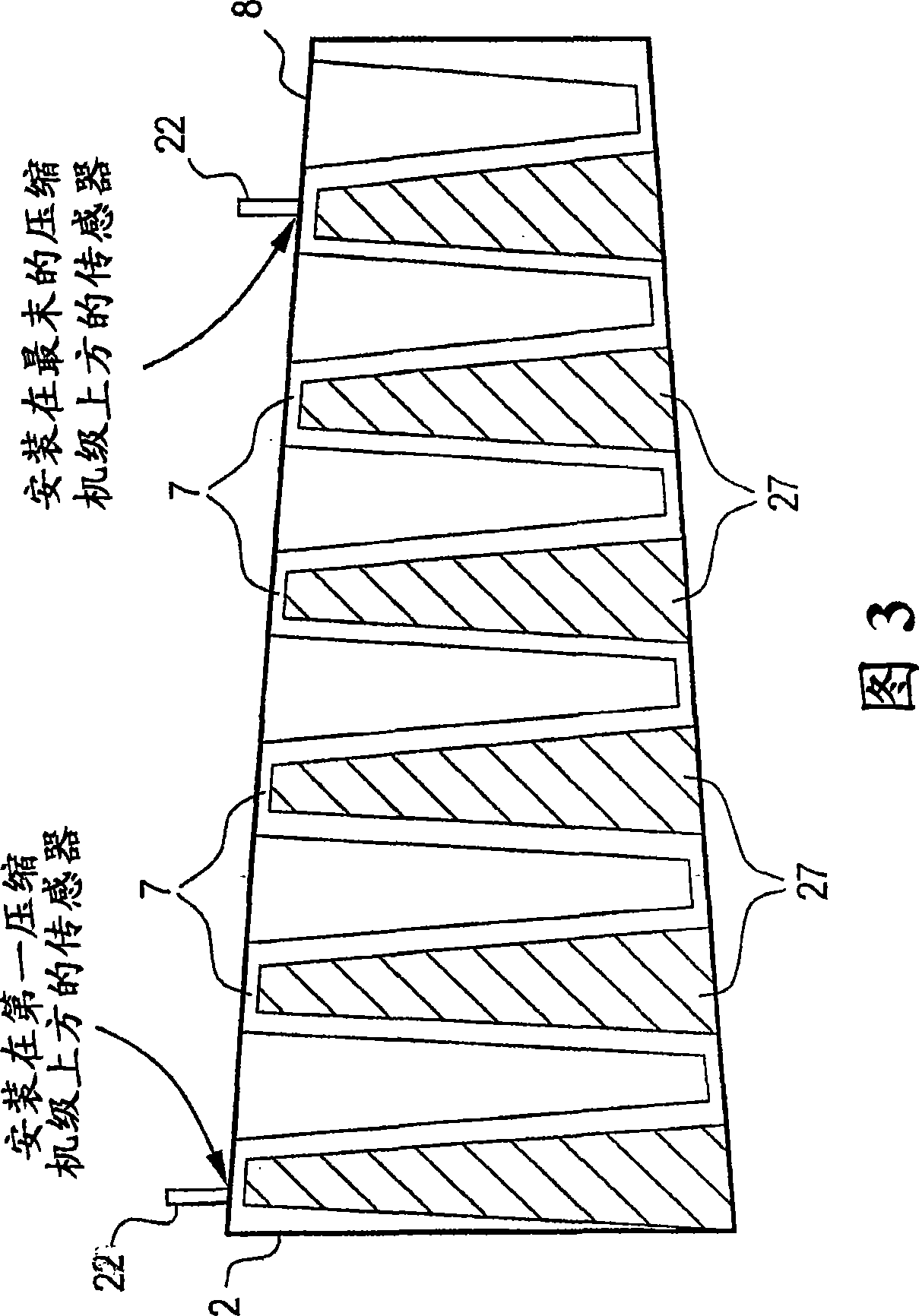

[0016] The present teachings provide embodiments of apparatus and methods for monitoring clearances between a plurality of compressor blades and a casing in a gas turbine. The present teachings provide for measuring clearances during gas turbine operation and controlling parameters of the gas turbine based on the measured clearances. The parameters are controlled in such a way as to provide a higher efficiency in the operation of the gas turbine than would be obtained without the device and method.

[0017] Typically, the gap is measured with a sensor that provides gap-related information to a control system. A control system, which may be included within a gas turbine engine controller, receives the information and controls certain parameters of the gas turbine based on the information. Two examples of controlled parameters are inlet intake heated air and fuel flow. Before proceeding to a detailed discussion of the embodiments, certain definitions are provided.

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com