Method for enhancing surface of microwave communication device through low-temperature molten salt electroplating of Ni-WC composite layer

A technology of microwave communication and low-temperature molten salt, applied in electrolysis components, electrolysis process, etc., can solve the problems of wasting energy and polluting electrolysis temperature, and achieve the effects of reducing energy consumption, simple and mild reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

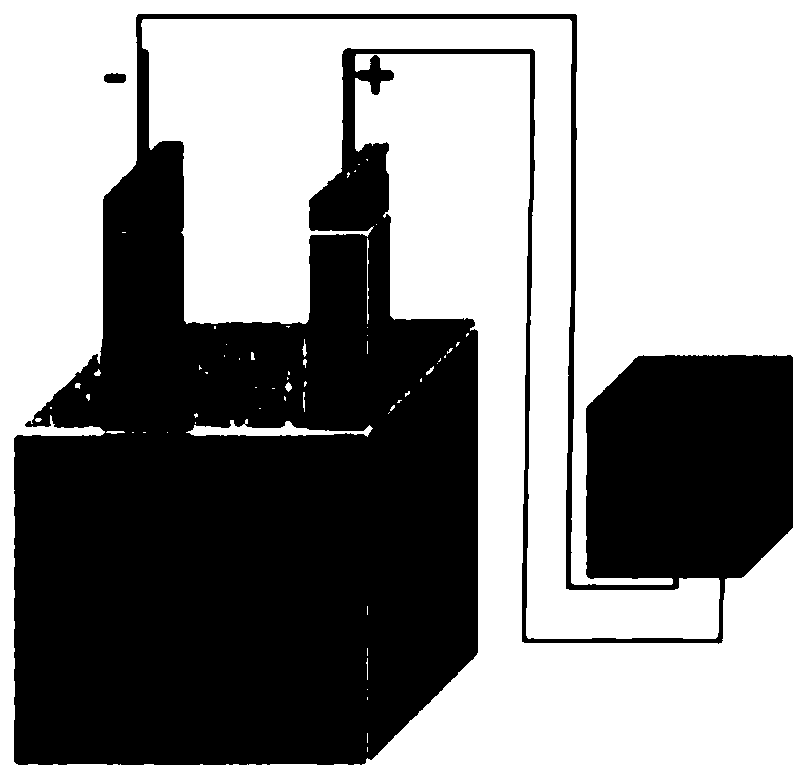

[0029] A method for enhancing the surface of a microwave communication device by electroplating a Ni-WC composite layer with low-temperature molten salt, comprising the following steps:

[0030] 1) Inorganic salt LiNO 3 、NaNO 3 、KNO 3 , Ca(NO 3 ) 2 、NaNO 2 、KNO 2 , LiCl, NaCl, KCl, CaCl 2 Dried and finely ground, made into mixed salt according to the percentage by weight of 15%: 8%: 10%: 5%: 10%: 30%: 2%: 5%: 5%: 10%, heated and melted at 100°C into a liquid state, then pour it into the electroplating tank and heat it to keep it in a liquid state. The melting point of the low-melting point mixed molten salt electroplating solution is 60°C. In order to have a high fluidity of the electrolyte, it is heated and melted at 100°C;

[0031] 2) Continue to add one of 0.5%-2% nickel chloride, 0.5%-2% nickel nitrate, 0.5%-2% nickel sulfate, and 1%-3% micronano tungsten carbide in the molten salt electroplating tank One or several kinds, and adding an appropriate amount of 0.5%-1...

Embodiment 2

[0045] A method for enhancing the surface of a microwave communication device by electroplating a Ni-WC composite layer with low-temperature molten salt, comprising the following steps:

[0046] 1) Inorganic salt LiNO 3 、NaNO 3 、KNO 3 , Ca(NO 3 ) 2 、NaNO 2 、KNO 2 , LiCl, NaCl, KCl, CaCl 2 Dried and finely ground, made into mixed salt according to the percentage by weight of 15%: 8%: 10%: 5%: 10%: 30%: 2%: 5%: 5%: 10%, heated and melted at 100°C into a liquid state, then pour it into the electroplating tank and heat it to keep it in a liquid state. The melting point of the low-melting point mixed molten salt electroplating solution is 60°C. In order to have a high fluidity of the electrolyte, it is heated and melted at 100°C;

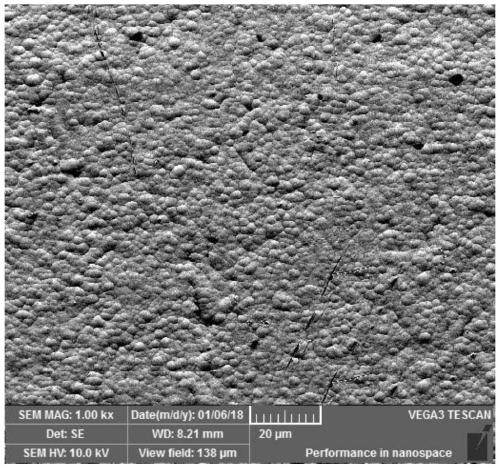

[0047] 2) Continue to add one or more of 1.25% nickel chloride, 1.25% nickel nitrate, 1.25% nickel sulfate, 2% micro-nano tungsten carbide in the molten salt electroplating tank, and add an appropriate amount of 0.75% by weight % sodium hydrogen ...

Embodiment 3

[0053] A method for enhancing the surface of a microwave communication device by electroplating a Ni-WC composite layer with low-temperature molten salt, comprising the following steps:

[0054] 1) Inorganic salt LiNO 3 、NaNO 3 、KNO 3 , Ca(NO 3 ) 2 、NaNO 2 、KNO 2 , LiCl, NaCl, KCl, CaCl 2 Dried and finely ground, made into mixed salt according to the percentage by weight of 15%: 8%: 10%: 5%: 10%: 30%: 2%: 5%: 5%: 10%, heated and melted at 100°C into a liquid state, then pour it into the electroplating tank and heat it to keep it in a liquid state. The melting point of the low-melting point mixed molten salt electroplating solution is 60°C. In order to have a high fluidity of the electrolyte, it is heated and melted at 100°C;

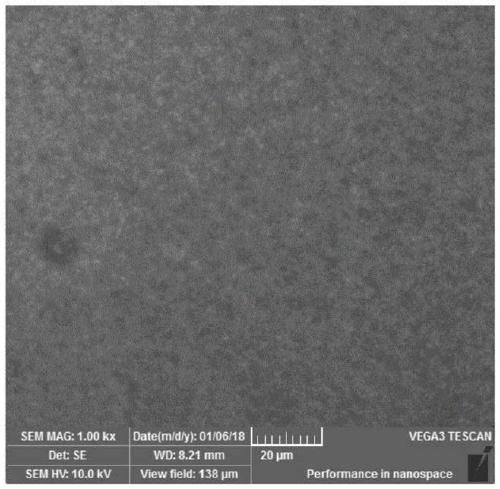

[0055] 2) Continue to add one or more of 2% nickel chloride, 2% nickel nitrate, 2% nickel sulfate, 3% micro-nano tungsten carbide in the molten salt electroplating tank, and add an appropriate amount of 1% by weight. % sodium hydrogen phosphate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com