Production process of 2-series aluminum alloy thin-wall profile machining part

A production process, aluminum alloy technology, applied in the production process field of 2-series aluminum alloy thin-walled profile processing parts, can solve the problems of low wetting speed, difficult correction, and structural cracking of parts, so as to reduce deformation and cracking tendency, overcome High intergranular corrosion performance, effect of improved intergranular corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A production process of a 2-series aluminum alloy thin-walled profile, comprising the following steps:

[0025] A. Ingredients: aluminum alloy ingredients according to the following mass percentages:

[0026] element Si Fe Cu mn Mg Ni Zn Ti Al content 0.60 0.70 3.90 0.4 0.50 0.10 0.3 0.15 margin

[0027] B. Smelting: Smelting the configured aluminum alloy, thoroughly degassing and slag removal, and casting an aluminum alloy ingot with qualified composition and structure. The melting temperature is 750°C. During the melting process, add hexachloroethane refining agent and stir evenly , after standing still for 15 minutes, the amount of hexachloroethane refining agent added is 0.4%;

[0028] C. Extrusion: Extrude aluminum alloy ingots to obtain aluminum alloy thin-walled profiles. The extrusion temperature is 440°C, the extrusion speed is 1.2m / min, and the extrusion ratio is 9;

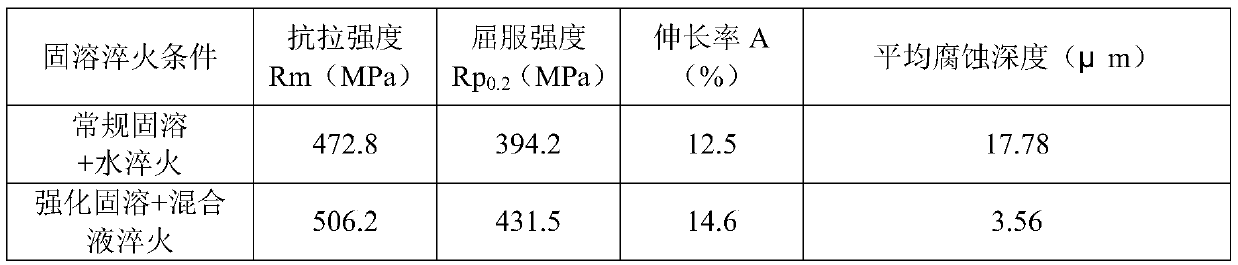

[0029] D. Enhanced solid solution: The aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com