Antistatic agent for spandex oiling agent and preparation method of antistatic agent

A technology of antistatic agent and spandex oil agent, which is applied in the direction of fiber type, textile and papermaking, fiber treatment, etc., can solve the problems that can not fully meet the production requirements, can not solve the problem of static electricity, does not consider compatibility, etc., and achieves raw material Inexpensive, improved uniformity, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

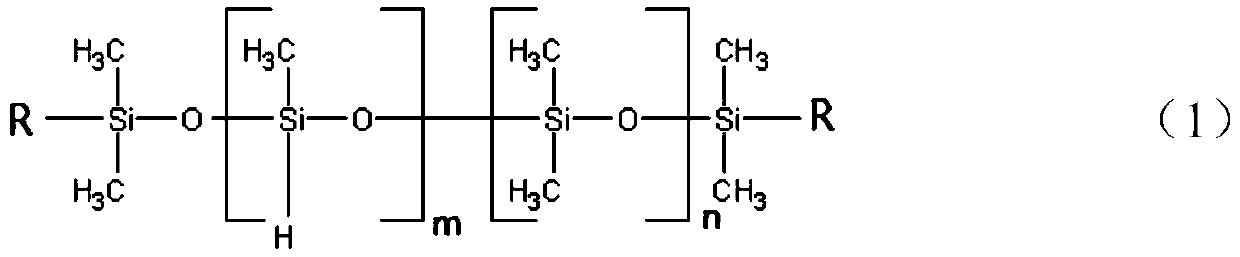

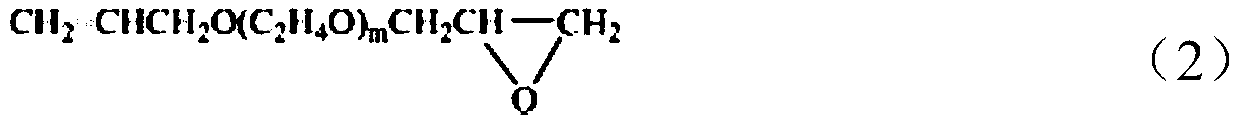

[0038] A kind of preparation method of antistatic agent for spandex oil agent, it comprises the following steps:

[0039] (1) Preparation of epoxy siloxane polymer: 400g hydrogen-containing siloxane polymer (hydrogen content 0.25%) and 228g allyl epoxy polyether (m=0) were added to high temperature and high pressure non-metallic In the lined airtight reaction kettle, vacuumize and replace nitrogen three times, start stirring and heating, so that the temperature of the liquid in the reaction kettle rises to 85°C, add a Pt catalyst (2ppm in terms of Pt), and continue to raise the temperature to control the temperature of the liquid in the reaction kettle At 100°C, continue to stir for 2 hours until there is no residual hydrogen-containing siloxane polymer;

[0040] (2) Distillation to remove impurities: vacuum distill the mixture obtained in step (1), the distillation process temperature is 140 ° C, and the distillation process pressure is maintained at 65 mm Hg to remove unreac...

Embodiment 2

[0044] A kind of preparation method of antistatic agent for spandex oil agent, it comprises the following steps:

[0045] (1) Preparation of epoxy siloxane polymer: 400g hydrogen-containing siloxane polymer (hydrogen content 0.25%) and 142g glycidyl methacrylate are added to a closed reaction kettle with high temperature and high pressure non-metallic lining , vacuumize and replace nitrogen three times, turn on stirring and heating, make the temperature of the liquid in the reactor rise to 80°C, add Pt catalyst (4ppm in terms of Pt), continue to raise the temperature, control the temperature of the liquid in the reactor at 90°C, and continue to stir the reaction 2.5 hours to no residual hydrogen-containing siloxane polymer;

[0046] (2) Distillation to remove impurities: vacuum distill the mixture obtained in step (1), the temperature of the distillation process is 100°C, the pressure of the distillation process is maintained at 20 mm Hg, and the unreacted raw materials and im...

Embodiment 3

[0050] A kind of preparation method of antistatic agent for spandex oil agent, it comprises the following steps:

[0051] (1) Preparation of epoxy siloxane polymer: 599g of hydrogen-containing siloxane polymer (0.167% hydrogen content) and 186g of 1,2 epoxy-4-vinylcyclohexane were added to high temperature and high pressure In the closed reaction kettle with non-metal lining, vacuumize and replace nitrogen three times, start stirring and heating, so that the temperature of the liquid in the reaction kettle rises to 60°C, add Pt catalyst (8ppm in terms of Pt), and continue to heat up, so that the liquid in the reaction kettle The temperature is controlled at 105°C, and the reaction is continuously stirred for 2 hours until there is no residual hydrogen-containing siloxane polymer;

[0052] (2) Distillation to remove impurities: vacuum distill the mixture obtained in step (1), the distillation process temperature is 170 ° C, and the distillation process pressure is maintained at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com