Preparation method of cellulose ether with high suspension, strong rheology and bleeding prevention

A cellulose ether and high-suspension technology, which is applied in the field of modification and synthesis of cellulose ether, can solve the problems of affecting pumpability and leveling, inconsistent surface and internal strength, and reducing product performance, so as to achieve dispersibility and solubility Effects of lifting, suspension and stability improvement, workability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

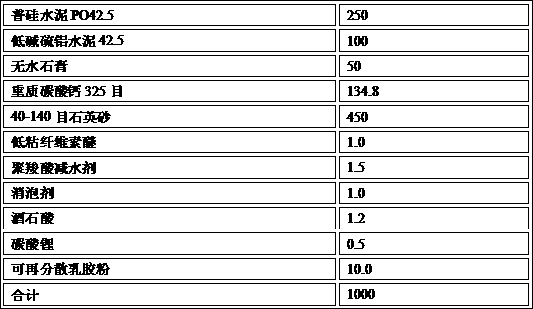

Embodiment 1

[0014] A preparation method of high-suspension, strong rheology, anti-bleeding cellulose ether, comprising the following steps:

[0015] (1) Preparation of cellulose ether with a viscosity of 400-1000mpa.s: impregnate the refined cotton with a 40% NaOH solution for 1 hour, then carry out alkalization treatment at 30°C, then seal the reactor and vacuumize it, and add A certain amount of etherification agent, the etherification agent is one of methyl chloride, propylene oxide, methyl chloride, and ethylene oxide, wherein the mass ratio of cotton fiber to etherification agent is 1:1.5-2.0, and then slowly heat up to React at 40°C for 2 hours, continue to heat up and react at 70°C for 1.5 hours, the prepared cellulose ether is at least one of hydroxypropyl methylcellulose ether or hydroxyethyl methylcellulose ether, the initiator It is at least one of potassium persulfate or sodium persulfate;

[0016] (2) Carry out modification and substitution treatment on the cellulose ether p...

Embodiment 2

[0018] The difference between Example 2 and Example 1 is that: when performing rheology modification treatment, the ratio of each component is roughly 2:1 by mass ratio of cellulose ether to water-soluble rheological polymerization modification monomer, wherein The water-soluble rheological polymerization modified monomer is ethylene oxide monomer and acrylamide monomer mixed at a ratio of 1:1, and the prepared cellulose has a viscosity of 430mpa.s.

Embodiment 3

[0020] The difference between Example 3 and Example 1 is that: when performing rheology modification treatment, the ratio of each component is approximately 3:1 by mass ratio of cellulose ether to water-soluble rheological polymerization modification monomer, wherein The water-soluble rheological polymerization modified monomer is 1:1 mixed substitution of ethylene oxide monomer and acrylamide monomer, and the viscosity of the prepared cellulose is 450mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com