Catalyst component for olefin polymerization, preparation method, catalyst and application thereof

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst components and its preparation, which can solve problems such as not being ideal enough to achieve the effects of low solvent content, inhibition of expansion, and low content of polymer powder fine powder

- Summary

- Abstract

- Description

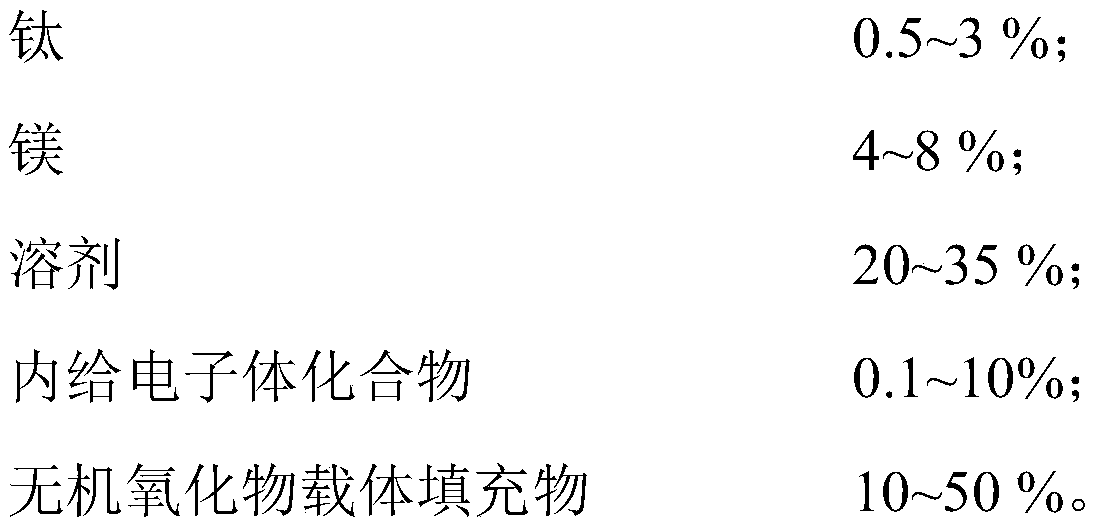

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Preparation of catalyst components

[0066] In a 250ml four-neck flask equipped with a temperature controller, a stirrer, and a reflux condenser, blown and protected by nitrogen, successively add 100ml of tetrahydrofuran (THF), 3.73 grams of magnesium chloride, and 0.89ml of TiCl under stirring. 4 , 0.18 g of N,N-dimethylacetamide, heated to 68° C. under stirring, and refluxed at this temperature for 2 hours to obtain the mother liquor. During this process, it has been kept in a nitrogen atmosphere (2 O);

[0067] In a 250ml four-neck flask equipped with a temperature controller, a stirrer, a reflux condenser, blown and protected by nitrogen, add 6.5 grams of silica gel (Cabot Corporation TS-610, particle diameter is 0.1~1 micron), Add the above mother liquor while stirring, and continue to reflux at 68° C. for 2 hours to completely disperse the silica gel in the mother liquor to obtain a slurry suspension. During this process, it has been kept in a nitrogen atmos...

Embodiment 2

[0072] (1) Preparation of catalyst components

[0073] In a 250ml four-necked flask equipped with a temperature controller, a stirrer, a reflux condenser, blown and protected by nitrogen, successively add 100ml tetrahydrofuran (THF) and 0.33 gram of magnesium powder (average particle diameter 80 ~100 microns) Then, slowly add 4ml of TiCl over 0.5 hours 4 , heated to 50° C., and stirred at constant temperature for 6 hours to obtain a solution of titanium trichloride, magnesium chloride and tetrahydrofuran. During this process, it has been kept in a nitrogen atmosphere (2 O);

[0074] In a 250ml four-necked flask equipped with a temperature controller, a stirrer, a reflux condenser, blown and protected by nitrogen, successively add 77ml tetrahydrofuran (THF), 3.79 grams of magnesium chloride, 33.3ml under stirring and let stand for 1 The supernatant of the above solution for 1 hour, 0.3 g of N,N-dimethylacetamide, was heated to 68° C. under stirring, and refluxed at this tempe...

Embodiment 3

[0080] (1) Preparation of catalyst components

[0081] In a 250ml four-necked flask equipped with a temperature controller, a stirrer, and a reflux condenser, blown and protected by nitrogen, successively add 100ml tetrahydrofuran (THF), 5.3 grams of magnesium chloride, and 2.1 grams of TiCl under stirring. 3 1 / 3AlCl 3 (TOSOH FINECHEM Corporation, TiCl3-AA), 0.38 g of N,N-dimethylacetamide, heated to 68° C. under stirring, and refluxed at this temperature for 2 hours to obtain the mother liquor. During this process, it has been kept in a nitrogen atmosphere (2 O);

[0082] In a 250ml four-necked flask equipped with a temperature controller, a stirrer, and a reflux condenser, blown and protected by nitrogen, add 7.2 grams of silica gel (Cabot Corporation TS-610, a particle size of 0.1 to 1 micron), Add the above mother liquor while stirring, and continue to reflux at 68° C. for 2 hours to completely disperse the silica gel in the mother liquor to obtain a slurry suspension. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com