Ultralow molecular weight hyaluronic acid and preparation method thereof

A technology of hyaluronic acid and hyaluronidase, which is applied in the direction of fermentation, etc., can solve the problems of high waste liquid treatment cost, unreported product composition, harsh reaction conditions, etc., and achieve stable product quality, narrow molecular weight distribution range, and short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

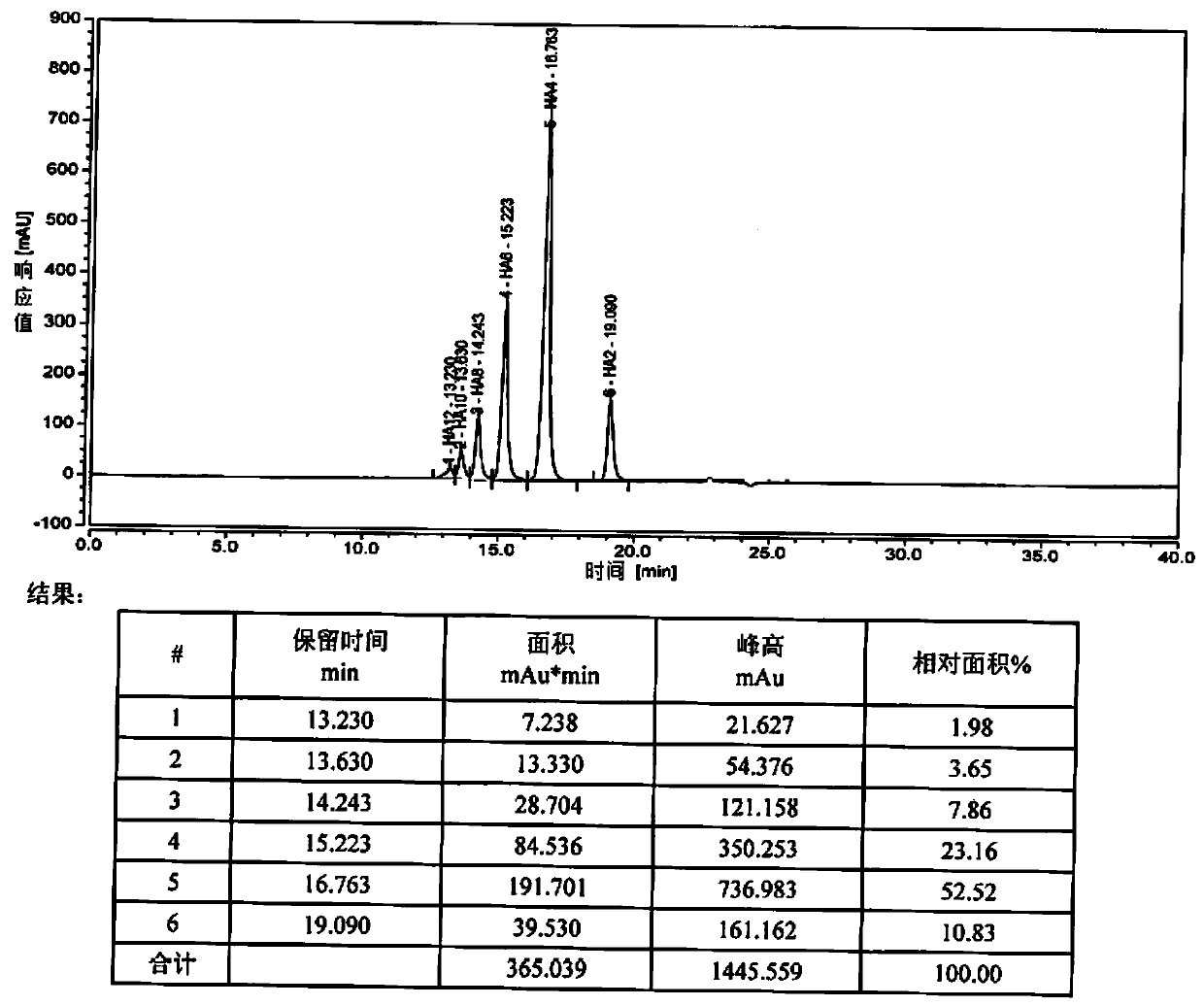

Image

Examples

Embodiment 1

[0049] Embodiment 1 enzymolysis reaction

[0050] In a 5L glass beaker, add 3L of purified water, control the stirring speed to 400rpm, control the temperature to 40°C, add hyaluronidase 1.5×10 8 U, the enzyme activity of the system is 5×10 4 U / mL, add 330g of macromolecular hyaluronic acid, after it is completely dissolved, adjust the pH of the solution to 5.5, keep the system at 40°C and stir for 24h.

Embodiment 2

[0051] Embodiment 2 enzymolysis reaction

[0052] In a 5L glass beaker, add 3L of purified water, control the stirring speed at 100rpm, control the temperature at 35°C, add hyaluronidase 1.2×10 8 U, the enzyme activity of the system is 4×10 4 U / mL, add 330g of macromolecular hyaluronic acid, after it is completely dissolved, adjust the pH of the solution to 6.0, keep the system at 35°C and stir for 24h.

Embodiment 3

[0053] Embodiment 3 enzymolysis reaction

[0054] In a 5L glass beaker, add 3L of purified water, control the stirring speed at 700rpm, control the temperature at 45°C, add hyaluronidase 3×10 8 U, the enzyme activity of the system is 1×10 5 U / mL, add 150g of macromolecular hyaluronic acid, after it is completely dissolved, adjust the pH of the solution to 5.0, keep the system at 45°C and stir for 36h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com