Water-based stone-like composite antiskid pavement and manufacturing method thereof

A technology imitating stone and water-based polymers, which is applied in the field of building materials, can solve the problems of short life, poor aging resistance, and pieces falling off, and achieve the effects of long service life, satisfactory weather resistance, and convenient paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

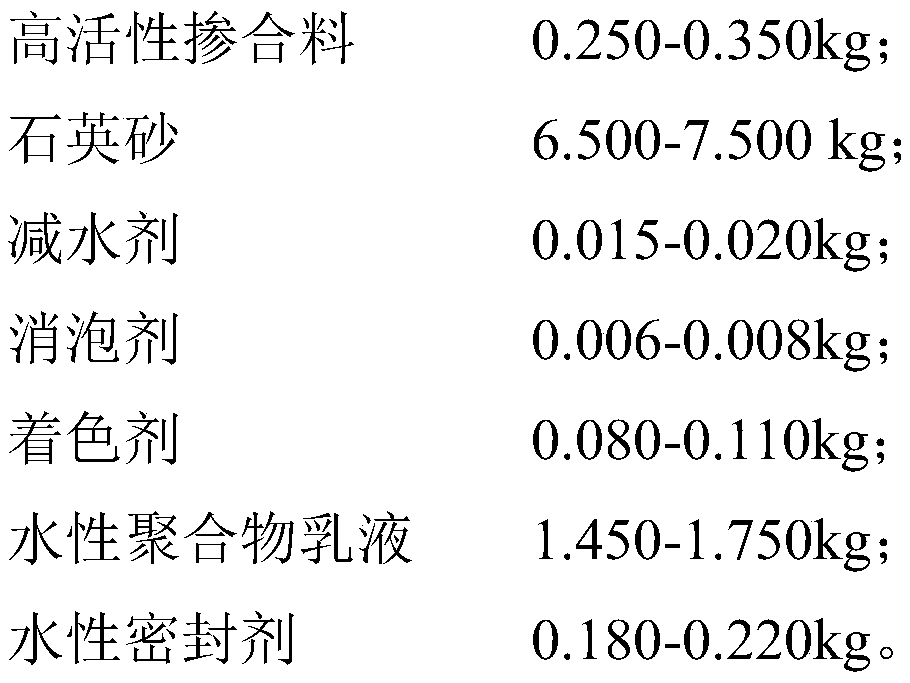

[0033] The present embodiment provides a kind of water-based imitation stone material composite non-slip pavement, the described non-slip pavement per square meter is made up of following composition:

[0034]

[0035]

[0036] The high-activity admixture is formed by mixing silica fume, mineral powder, fly ash, water reducer and early strength agent in a ratio of 1:0.6:0.4:0.005:0.001.

[0037] The preparation method of the above-mentioned water-based imitation stone composite non-slip pavement comprises the following steps:

[0038] 1) Adhesive waterproof layer pavement: accurately measure the amount of each component of the adhesive waterproof material, and adopt the following proportioning ratio, the 42.5 ordinary Portland cement: high-activity admixture (composed of silica fume, mineral powder, pulverized coal Ash, water reducing agent and early strength agent are mixed according to the ratio of 1:0.6:0.4:0.005:0.001): high-quality quartz sand: polycarboxylate modif...

Embodiment 2

[0046] The present embodiment provides a kind of water-based imitation stone material composite non-slip pavement, the described non-slip pavement per square meter is made up of following composition:

[0047]

[0048] The high-activity admixture is formed by mixing silica fume, mineral powder, fly ash, water reducer and early strength agent in a ratio of 1:0.6:0.4:0.005:0.001.

[0049] The preparation method of the above-mentioned water-based imitation stone composite non-slip pavement comprises the following steps:

[0050] 1) Adhesive waterproof layer pavement: accurately measure the amount of each component of the adhesive waterproof material, and adopt the following proportioning ratio, the 42.5 ordinary Portland cement: high-activity admixture (composed of silica fume, mineral powder, pulverized coal Ash, water reducing agent and early strength agent are mixed according to the ratio of 1:0.6:0.4:0.005:0.001): high-quality quartz sand: polycarboxylate modified ether po...

Embodiment 3

[0058] The present embodiment provides a kind of water-based imitation stone material composite non-slip pavement, the described non-slip pavement per square meter is made up of following composition:

[0059]

[0060] The high-activity admixture is formed by mixing silica fume, mineral powder, fly ash, water reducer and early strength agent in a ratio of 1:0.6:0.4:0.005:0.001.

[0061] The preparation method of the above-mentioned water-based imitation stone composite non-slip pavement comprises the following steps:

[0062]1) Adhesive waterproof layer pavement: accurately measure the amount of each component of the adhesive waterproof material, and adopt the following proportioning ratio, the 42.5 ordinary Portland cement: high-activity admixture (composed of silica fume, mineral powder, pulverized coal Ash, water reducer and early strength agent are mixed according to the ratio of 1:0.6:0.4:0.005:0.001): high-quality quartz sand: polycarboxylate modified ether powder wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com