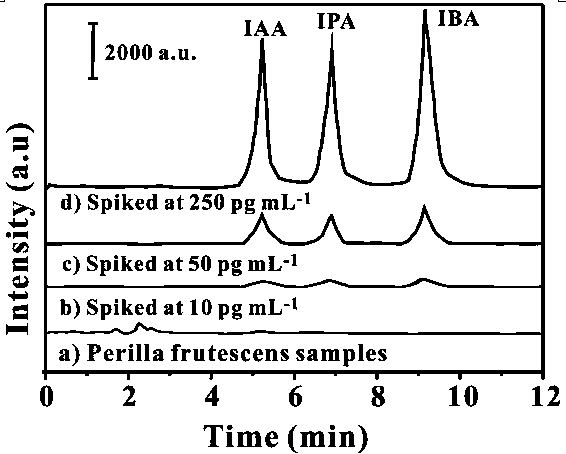

Preparation of MOF-based hydroxylated magnetic nitrogen-doped carbon nanotubes, and uses in detection of auxin content in tea leaves

A nitrogen-doped carbon and nanotube technology, applied in the fields of carbon nanotubes, nanocarbons, inorganic chemistry, etc., can solve the problems of poor hydrophilicity, not easy to disperse, easy to settle, etc., achieve high selectivity, enhance water solubility, The effect of stabilization of the reaction product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

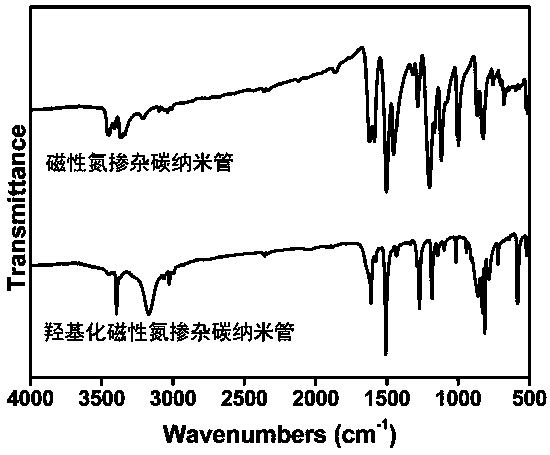

[0031] A method for synthesizing a hydroxylated magnetic nitrogen-doped carbon nanotube material, comprising the following steps:

[0032] 1.1 Preparation of magnetic nitrogen-doped carbon nanotube materials:

[0033] (a) Dissolve 2.0 g of 2-methylimidazole (2-MeIm) in 20 mL of methanol / ethanol mixed solution (v:v=1:1), and ultrasonically dissolve; another 1.75 g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 20 mL methanol / ethanol mixed solution (v:v=1:1);

[0034] (b) Mix the two clear solutions, stir for 10 s, and then let stand at room temperature for 20 h;

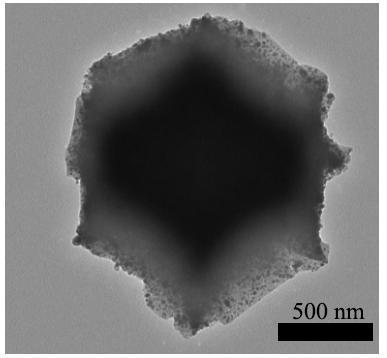

[0035] (c) After the reaction was completed, the resulting product was washed 3 times with ethanol, centrifuged at a speed of 5000 rpm for 3 min, and the resulting product was vacuum-dried overnight at 80° C. to obtain purple ZIF-67 crystals;

[0036] (d) Put 2.0 g ZIF-67 in a tube furnace and raise the temperature to 250°C at a rate of 5 °C / min, then increase the temperature to 450 °C at a rate o...

Embodiment 2

[0042] A method for synthesizing a hydroxylated magnetic nitrogen-doped carbon nanotube material, comprising the following steps:

[0043] 1.1 Preparation of magnetic nitrogen-doped carbon nanotube materials:

[0044] (a) Dissolve 2.0 g of 2-methylimidazole (2-MeIm) in 20 mL of methanol / ethanol mixed solution (v:v=1:1), and ultrasonically dissolve; another 1.75 g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 20mL methanol / ethanol mixed solution (v:v=1:1);

[0045] (b) Mix the two clear solutions, stir for 10 s, and then let stand at room temperature for 20 h;

[0046] (c) After completion of the reaction, the resulting product was washed 3 times with ethanol, centrifuged at a speed of 5000 rpm for 3 min, and the resulting product was vacuum-dried overnight at 80° C. to obtain purple ZIF-67 crystals;

[0047] (d) Put 2.0 g ZIF-67 in a tube furnace and raise the temperature to 250°C at a rate of 5 °C / min, then increase the temperature to 450 °C at a rate of...

Embodiment 3

[0052] A method for synthesizing a hydroxylated magnetic nitrogen-doped carbon nanotube material, comprising the following steps:

[0053] 1.1 Preparation of magnetic nitrogen-doped carbon nanotube materials:

[0054] (a) Dissolve 2.0 g of 2-methylimidazole (2-MeIm) in 20 mL of methanol / ethanol mixed solution (v:v=1:1), and ultrasonically dissolve; another 1.75 g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 20 mL methanol / ethanol mixed solution (v:v=1:1);

[0055] (b) Mix the two clear solutions, stir for 10 s, and then let stand at room temperature for 20 h;

[0056] (c) After the reaction was completed, the resulting product was washed 3 times with ethanol, centrifuged at a speed of 5000 rpm for 3 min, and the resulting product was vacuum-dried overnight at 80 °C to obtain purple ZIF-67 crystals;

[0057] (d) Put 2.0 g ZIF-67 in a tube furnace and raise the temperature to 250°C at a rate of 5 °C / min, then increase the temperature to 450 °C at a rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com