Method for preparing oil-in-water emulsion coated plant essential oil by using glycerol monolaurate

A technology of oil-in-water emulsion and monolauric acid monoglyceride, which is applied in the forming or processing of animal feed, application, food science, etc., can solve the problems of poor water solubility and low utilization rate of monolaurin glyceride, and overcome the volatile , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 100 parts of attapulgite in a pre-mixer, and spray oregano essential oil accounting for 15% of the attapulgite mass fraction into the pre-mixer under stirring; after the spraying is finished, grind it in a Raymond mill for 2 hours for later use;

[0026] At a stirring rate of 2000 rpm, disperse Tween 20 and linseed oil in water, then add hot melted lauric acid dry oil, continue stirring for 30 minutes and set aside. Among them, the mass fraction of Tween 20 in the system is 0.05%, the mass fraction of linseed oil in the system is 10%, and the mass fraction of lauric acid dry oil in the system is 5%;

[0027] Take 15 parts of the prepared oil-in-water emulsion in the blender, and spray it on the surface of the attapulgite carrying oregano essential oil by spraying. After the spraying, continue to stir for 20 minutes, and then transfer the mixture to the roller machine. Thin flakes of 1~2mm are finally dried at 80°C, crushed, and packaged to obtain samples. The min...

Embodiment 2

[0029] Weigh 100 parts of attapulgite in a pre-mixer, spray carvacrol with a mass fraction of attapulgite of 40% into the pre-mixer under stirring, and grind in a Raymond mill for 3 hours after the spraying is over;

[0030] At a stirring rate of 3000 rpm, disperse Tween 60 and soybean oil in water, then add hot melted lauric acid dry oil, continue stirring for 20 minutes and set aside. Among them, the mass fraction of Tween 60 in the system is 0.25%, the mass fraction of soybean oil in the system is 5%, and the mass fraction of lauric acid dry oil in the system is 10%;

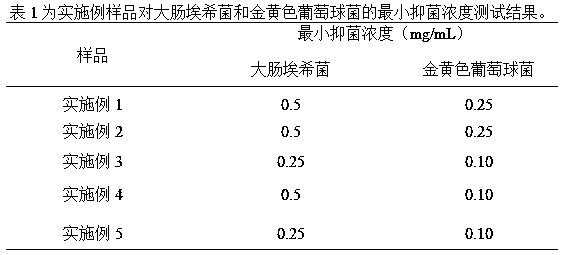

[0031] Take 20 parts of the prepared oil-in-water emulsion in the blender, and spray it on the surface of the attapulgite loaded with carvacrol by spraying. After the spraying, continue stirring for 15 minutes, and then transfer the mixture to the roller machine. Thin flakes of 1~2mm are finally dried at 80°C, crushed, and packaged to obtain samples. The minimum inhibitory concentration test results of the s...

Embodiment 3

[0033] Weigh 100 parts of attapulgite in the pre-mixer, spray attapulgite mass fraction 25% carvacrol and 15% cinnamaldehyde compound plant essential oil into the pre-mixer under stirring, after the spraying is finished, Grind in Raymond mill for 4h for later use;

[0034] At a stirring rate of 5000 rpm, disperse Tween 40, corn rapeseed oil and mixed vegetable oil in water, then add hot melted lauric acid dry oil, keep stirring for 25 minutes and set aside. Among them, the mass fraction of Tween 40 in the system is 0.1%, the mass fraction of corn oil in the system is 2.5%, the mass fraction of rapeseed oil in the system is 2.5%, and the mass fraction of lauric acid dry oil in the system 15%;

[0035] Take 25 parts of the prepared oil-in-water emulsion in a blender, and spray it onto the surface of the attapulgite pre-loaded with carvacrol and cinnamaldehyde compound plant essential oil by spraying. After the spraying, continue stirring for 20 minutes, and then transfer the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com