Reactor and method for continuous polymerisation

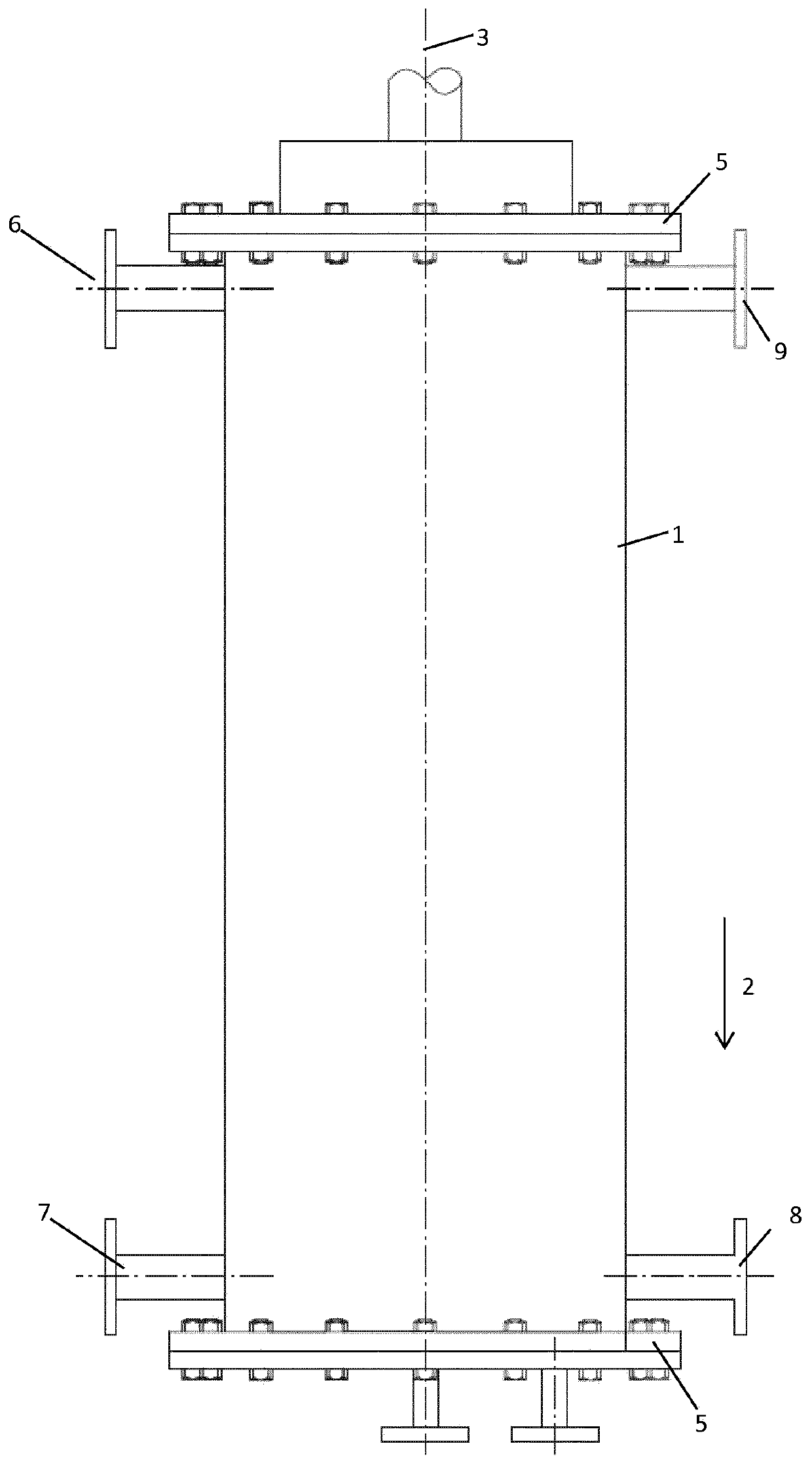

A technology for reactors and reactor shells, which is applied to tubular reactors. Reactors are used in the field of continuous production of polymers and synthetic rubbers. It can solve the problems of poor mixing and retention in reactors, undesired problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

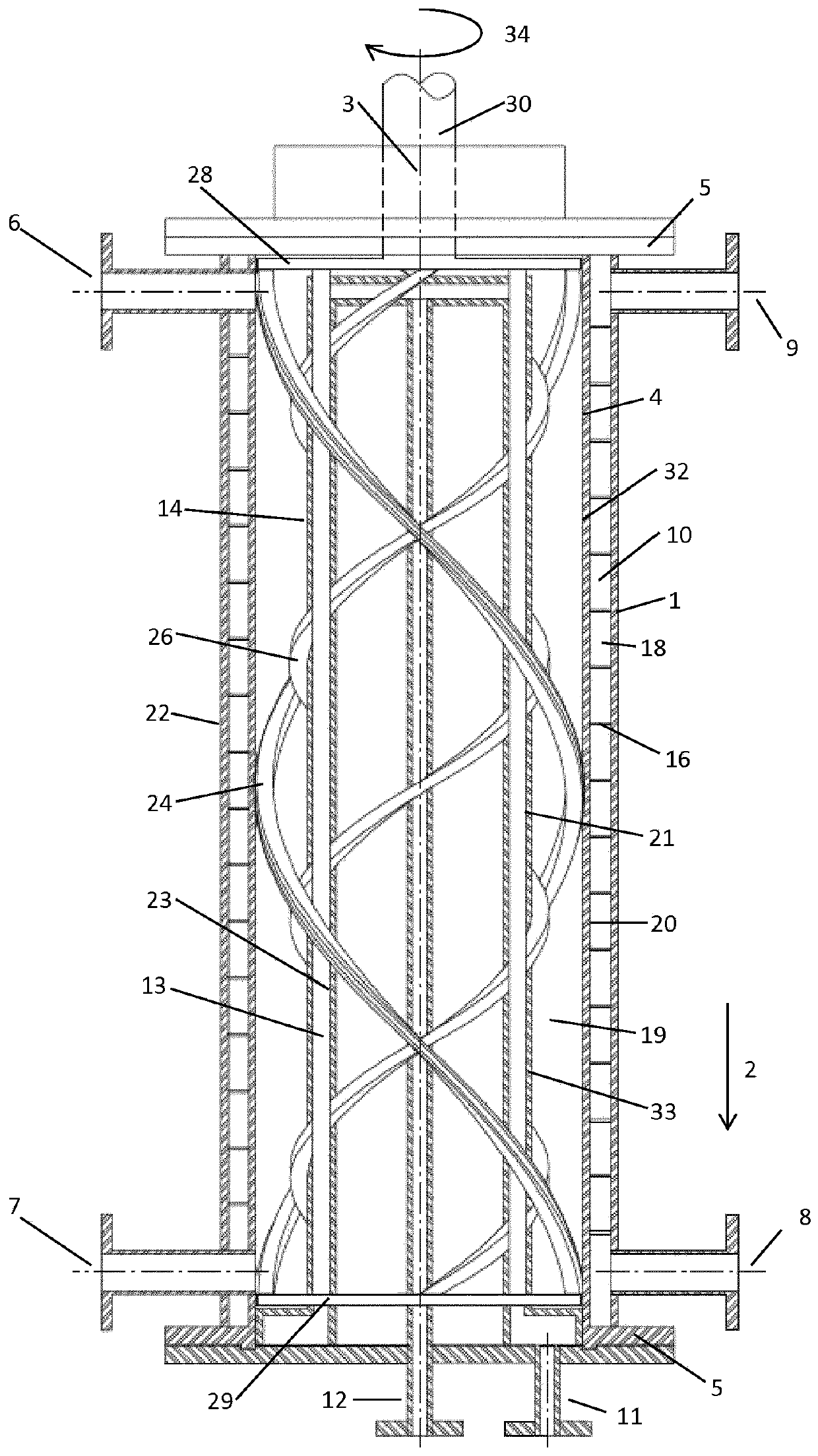

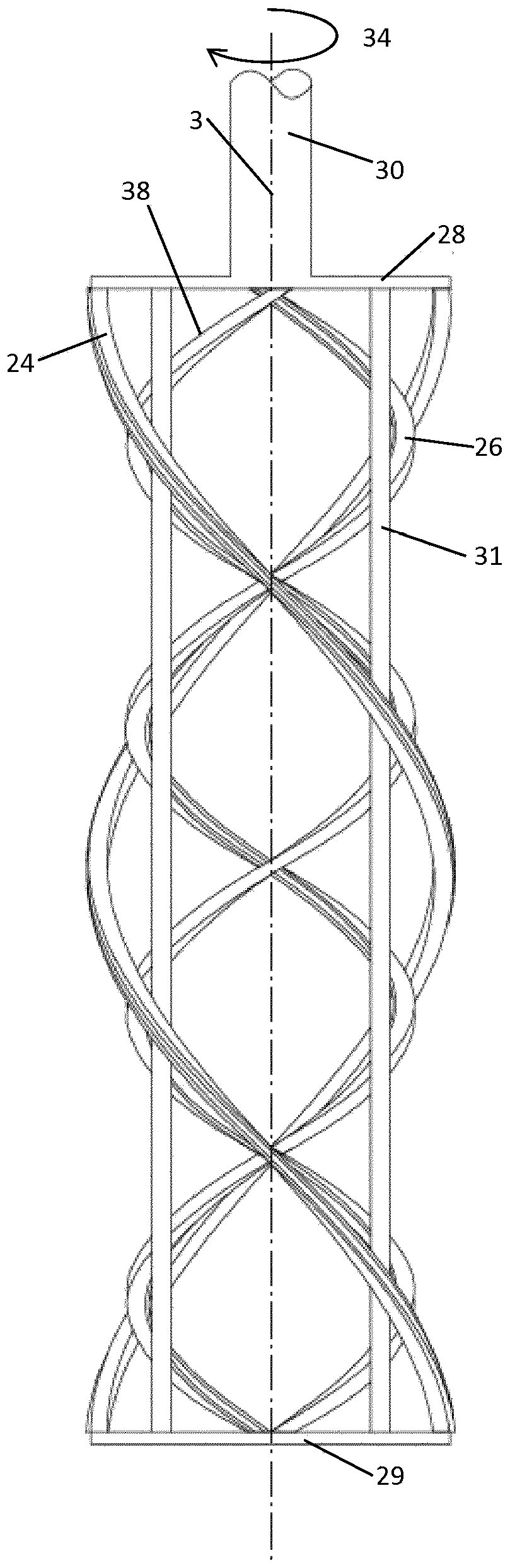

[0113] A reaction solution consisting of 33.5% by weight of solvent (alkane) and 1.5% by weight of isoprene and 65% by weight of isobutene as monomers was continuously metered into a test reactor with a length L of 320 mm and a diameter of D 100 mm (L / D=3.2), with a central displacement body with a displacement body diameter d of 70 mm (d / D=0.7) and a stirrer with four helical mixing elements throughout the reactor length, two of which A helical mixing element is in each case close to the wall on the outer surface of the reactor housing and two helical mixing elements are close to the wall on the surface of the inner displacement body (each at a distance of about 1 mm). The reactant flow was calibrated such that the average residence time in the reactor was 15 min. The reactor is completely filled with liquid.

[0114]To activate the polymerization, a solution of initiator (ethylaluminum dichloride, EADC) was additionally dosed in such an amount that the proportion of polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com