Prefabricated assembled solid single-column pier based on root expanded section and construction method thereof

A technology of enlarging the section and prefabricating and assembling. It is used in the erection/assembly of bridges, bridges, bridge parts, etc. It can solve the problems of weakened section, reduced stiffness and strength, and damage of piers in the connecting part, so as to achieve convenient and fast construction and improve crack resistance. The effect of stability and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows.

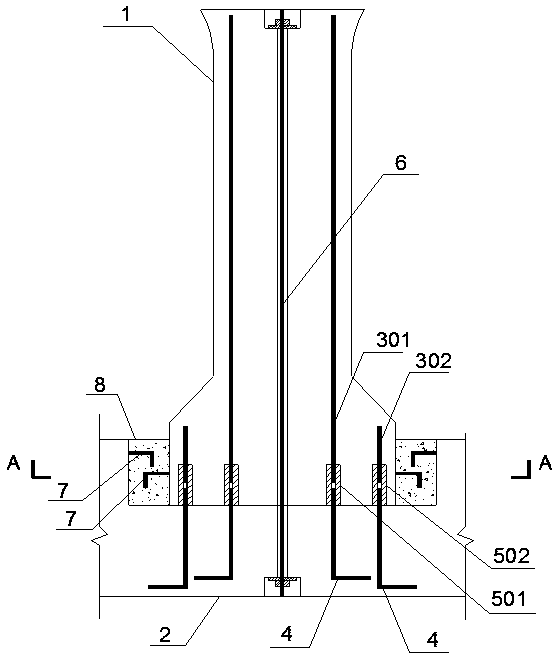

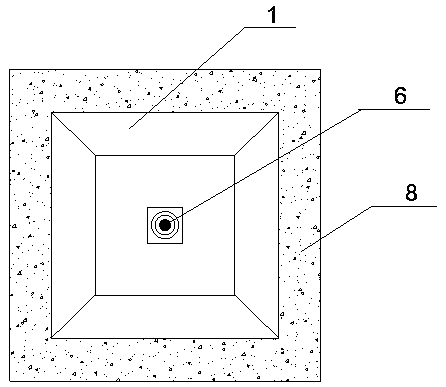

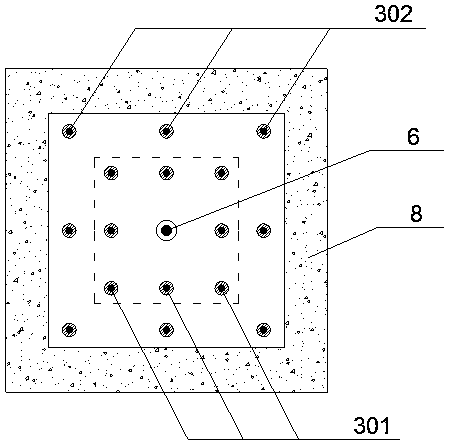

[0018] like Figure 1-3 As shown, a prefabricated and assembled solid single-column pier based on the enlarged section of the root includes a cap 2 and a pier column 1 located on the cap. The upper surface of the cap is provided with a longitudinal groove, and the root of the pier is partially enlarged and placed in the On the longitudinal groove, the gap between the inner wall of the longitudinal groove and the outer wall of the root of the pier column is poured with fiber reinforced concrete FRC connecting belt 8. Fibre concrete FRC is poured at the groove to fill the gap between the pier column and the bearing platform, so that the pier column and the bearing platform are closely connected; the longitudinal bars of the pier column and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com