Method for preparing dried tangerine or orange peel liquor by utilizing pichia pastoris

A technology of Pichia pastoris and tangerine peel, which is applied in microorganism-based methods, biochemical equipment and methods, preparation of alcoholic beverages, etc., can solve the problems of low content of flavonoids in tangerine peel, heavy bitterness and astringency in tangerine peel wine, and insufficient aroma of wine body. and other problems, to achieve the effect of full-bodied wine, improving the utilization rate of active ingredients and expanding the richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

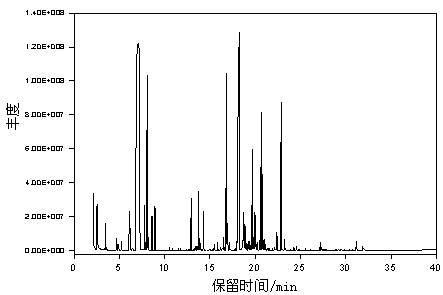

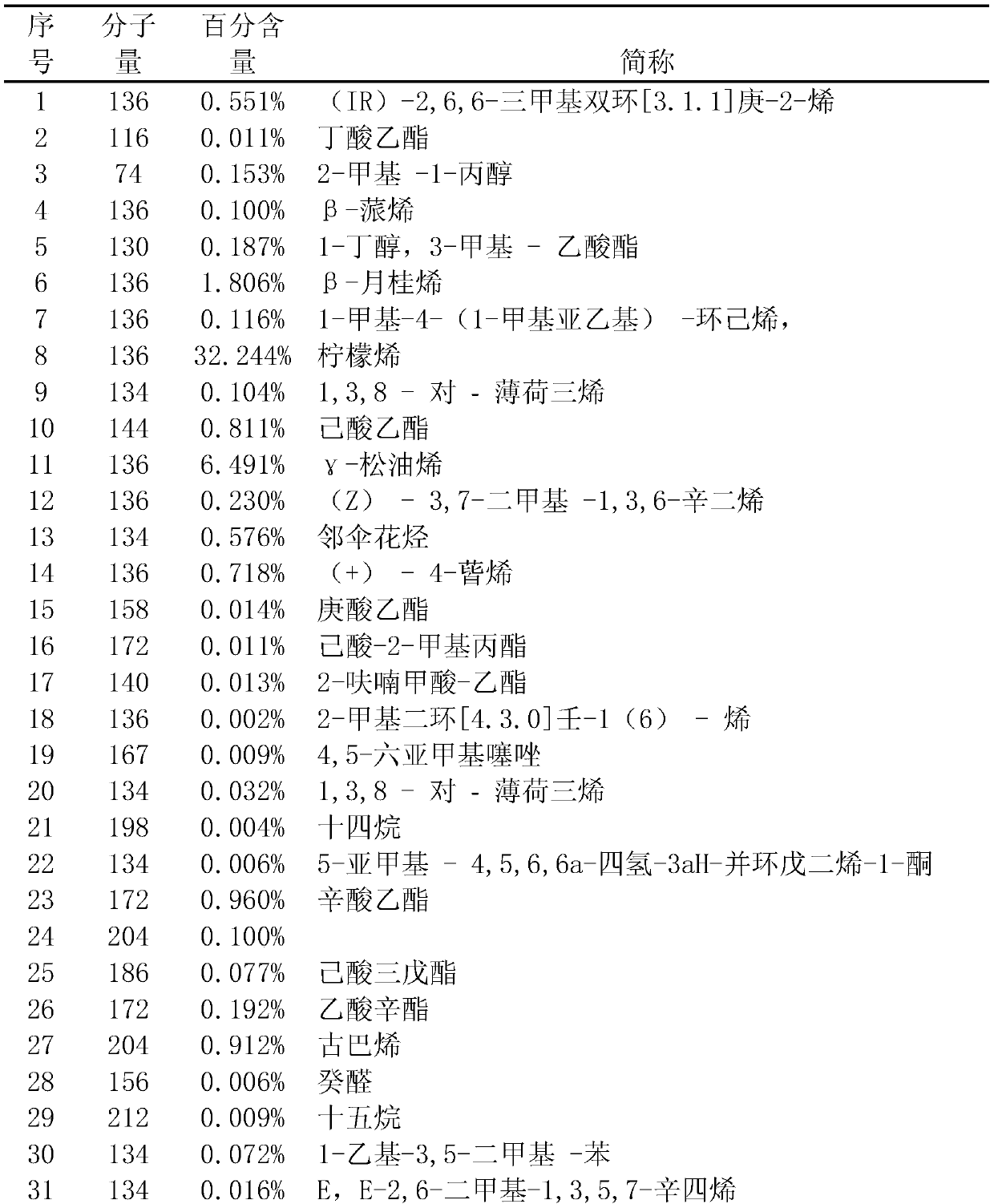

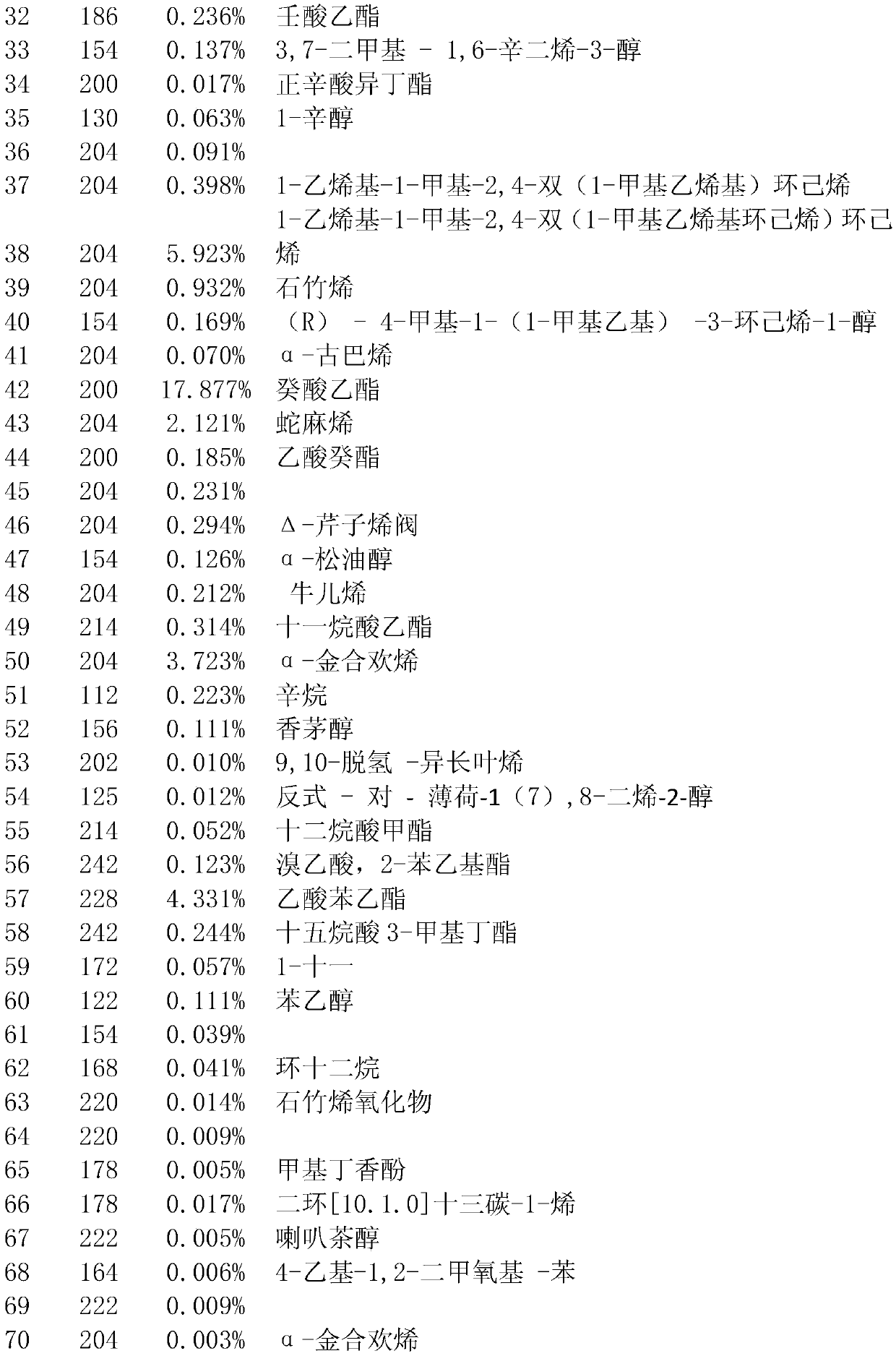

Image

Examples

Embodiment 1

[0015] A method utilizing Pichia yeast to prepare tangerine peel wine, comprising the following steps:

[0016] (1) Chenpi pretreatment: Chenpi is crushed and sieved with 20 meshes, water is added to the tangerine peel grains according to the material-to-water ratio of 5%, and kept at a temperature of 22° C. for 28 minutes;

[0017] (2) Preparation of fermented material: add brown sugar and mix evenly by 40% of the mixed material liquid quality to obtain fermented material;

[0018] (3) Fermentation of tangerine peel: Pichia kudriavzevii, FBKL2.0008 was activated and cultured on wort solid slant medium for 2 days, then inserted into wort liquid medium, and cultured for 2 days at 28°C. 9% of the volume of the fermentation material was inserted into the activated Pichia yeast, and fermented at 28° C. for 4 days to obtain a fermentation liquid;

[0019] (4) Packing: After the fermented liquid is filtered, packed, and sterilized to get the tangerine peel wine.

Embodiment 2

[0021] A method utilizing Pichia yeast to prepare tangerine peel wine, comprising the following steps:

[0022] (1) Chenpi pretreatment: Chenpi is crushed and sieved with 20 meshes, water is added to the tangerine peel grains according to the material-to-water ratio of 5%, and the temperature is kept at 20° C. for 30 minutes;

[0023] (2) Preparation of fermented material: add brown sugar and mix evenly by 40% of the mixed material liquid quality to obtain fermented material;

[0024] (3) Fermentation of tangerine peel: Pichia kudriavzevii, FBKL2.0008 was activated and cultured on the wort solid slant medium for 2 days, then inserted into the wort liquid medium, and cultured for 2 days at 28°C. 8% of the volume of the fermentation material was inserted into the activated Pichia yeast, and fermented at 28° C. for 5 days to obtain a fermentation liquid;

[0025] (4) Packing: After the fermented liquid is filtered, packed, and sterilized to get the tangerine peel wine.

Embodiment 3

[0027] A method utilizing Pichia yeast to prepare tangerine peel wine, comprising the following steps:

[0028] (1) Chenpi pretreatment: Chenpi is crushed and sieved with 20 meshes, water is added to the tangerine peel grains according to the material-to-water ratio of 5%, and kept at a temperature of 18° C. for 32 minutes;

[0029] (2) Preparation of fermented material: add brown sugar and mix evenly by 30% of the mixed material liquid quality to obtain fermented material;

[0030] (3) Fermentation of tangerine peel: Pichia kudriavzevii, FBKL2.0008 was activated and cultured on wort solid slant medium for 3 days, then inserted into wort liquid medium, and cultured at 28°C for 2 days, according to 7% of the volume of the fermentation material was inserted into the activated Pichia pastoris, and fermented at 28°C for 6 days to obtain a fermentation liquid;

[0031] (4) Packing: After the fermented liquid is filtered, packed, and sterilized to get the tangerine peel wine.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com