Anti-static anti-fouling plastic film for packaging

A plastic film and anti-static technology, applied in the field of packaging, can solve the problems of unhygienic food or articles, film or bag vacuuming or oil fume, etc., achieve low surface activity, good packaging effect, and avoid the effect of dust adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

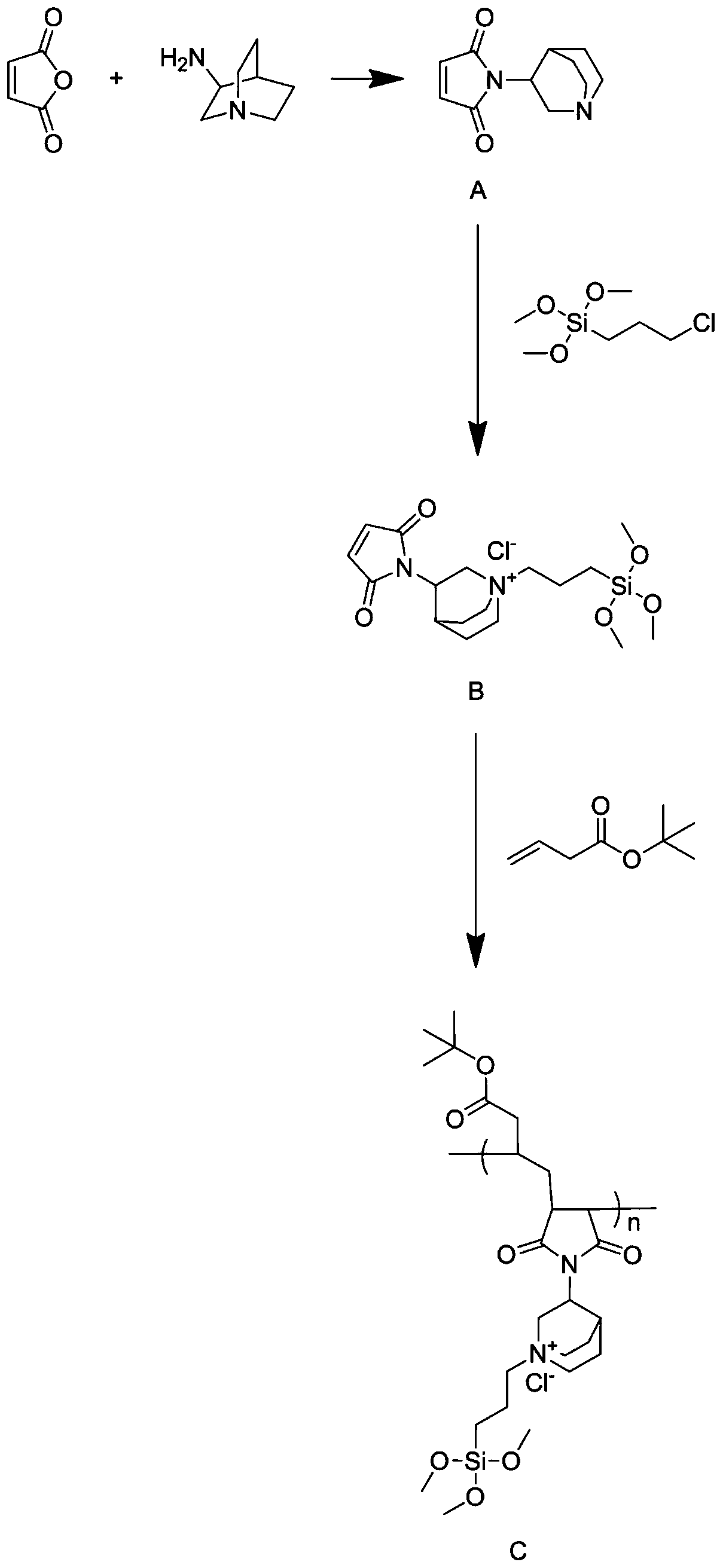

Method used

Image

Examples

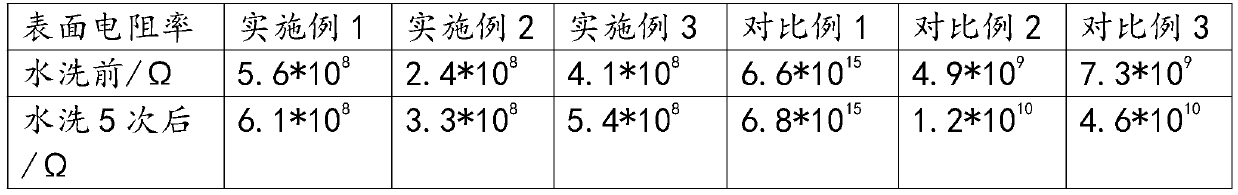

Embodiment 1

[0036] An antistatic and antifouling plastic film for packaging, made of the following raw materials in parts by weight: 50 g of low-density polyethylene, 40 g of linear low-density polyethylene, 3 g of plasticizer, 0.5 g of antistatic and antifouling additives, heat-stabilizing Agent 0.5g, lubricant 2g,

[0037] Described plasticizer is polyethylene glycol;

[0038] Described thermal stabilizer is triphenyl phosphite;

[0039] Described lubricant is magnesium stearate;

[0040] The production process of the antistatic and antifouling plastic film for packaging specifically includes the following steps:

[0041] The first step, premixing: mix low-density polyethylene, linear low-density polyethylene, plasticizer, antistatic and antifouling additives, heat stabilizer, and lubricant;

[0042]The second step, blow molding: inject the premixed material into the plastic blown film machine, melt it at high temperature in four stages of 130°C, 140°C, 150°C, and 160°C, and extrude ...

Embodiment 2

[0046] An antistatic and antifouling plastic film used for packaging is made of the following raw materials in parts by weight: 80g of low-density polyethylene, 30g of linear low-density polyethylene, 2g of plasticizer, 1.2g of antistatic and antifouling additives, heat-stabilizing Agent 1g, lubricant 1.5g,

[0047] Described plasticizer is polyethylene glycol;

[0048] Described thermal stabilizer is triphenyl phosphite;

[0049] Described lubricant is zinc stearate;

[0050] The production process of the antistatic and antifouling plastic film for packaging specifically includes the following steps:

[0051] The first step, premixing: mix low-density polyethylene, linear low-density polyethylene, plasticizer, antistatic and antifouling additives, heat stabilizer, and lubricant;

[0052] The second step, blow molding: inject the premixed material into the plastic blown film machine, melt it at high temperature in four stages of 130°C, 140°C, 150°C, and 160°C, and extrude i...

Embodiment 3

[0055] An antistatic and antifouling plastic film for packaging, made of the following raw materials in parts by weight: 70g of low-density polyethylene, 35g of linear low-density polyethylene, 3g of plasticizer, 1g of antistatic and antifouling additive, heat stabilizer 1g, lubricant 2g,

[0056] Described plasticizer is polyethylene glycol;

[0057] Described thermal stabilizer is triphenyl phosphite;

[0058] Described lubricant is sodium stearate;

[0059] The production process of the antistatic and antifouling plastic film for packaging specifically includes the following steps:

[0060] The first step, premixing: mix low-density polyethylene, linear low-density polyethylene, plasticizer, antistatic and antifouling additives, heat stabilizer, and lubricant;

[0061] The second step, blow molding: inject the premixed material into the plastic blown film machine, melt it at high temperature in four stages of 130°C, 140°C, 150°C, and 160°C, and extrude it into a film aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com