Sandwich structure composite material and OOA preparation method thereof

A composite material and sandwich structure technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of strict structural weight requirements, inability to meet low-cost manufacturing and structural lightweight, application limitations, etc. Reduced material cost, low comprehensive manufacturing cost, and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

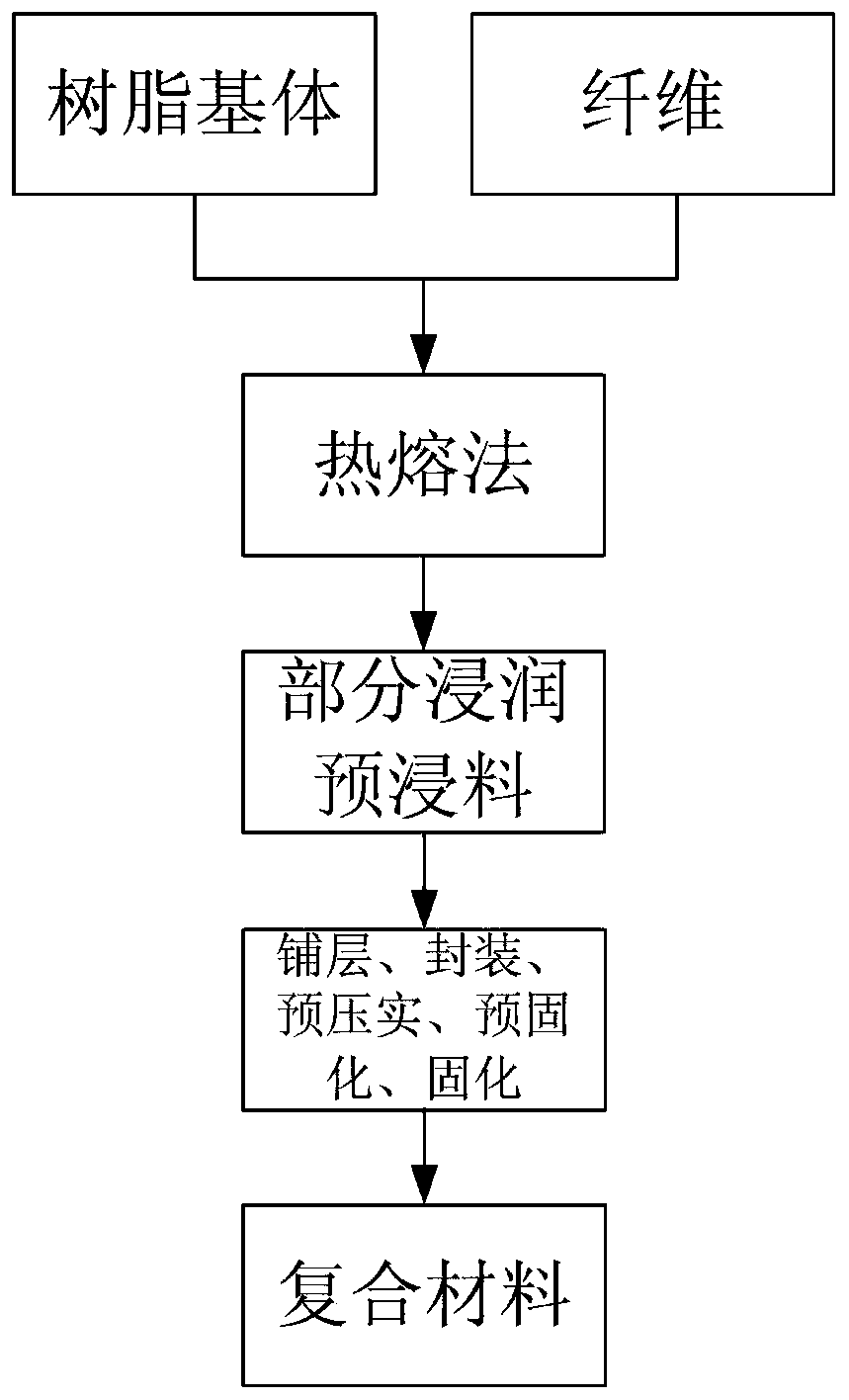

Method used

Image

Examples

Embodiment 1

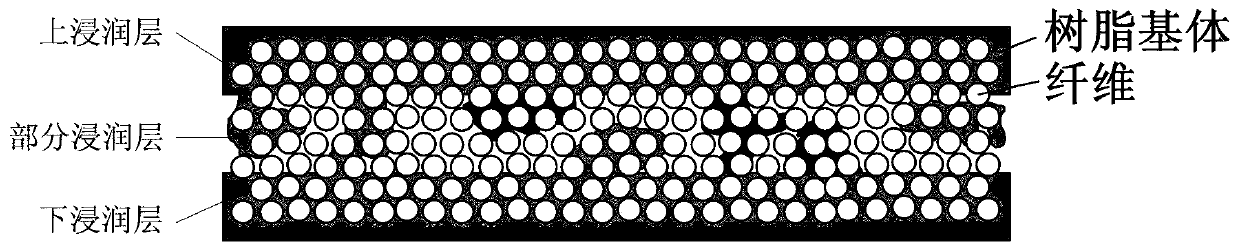

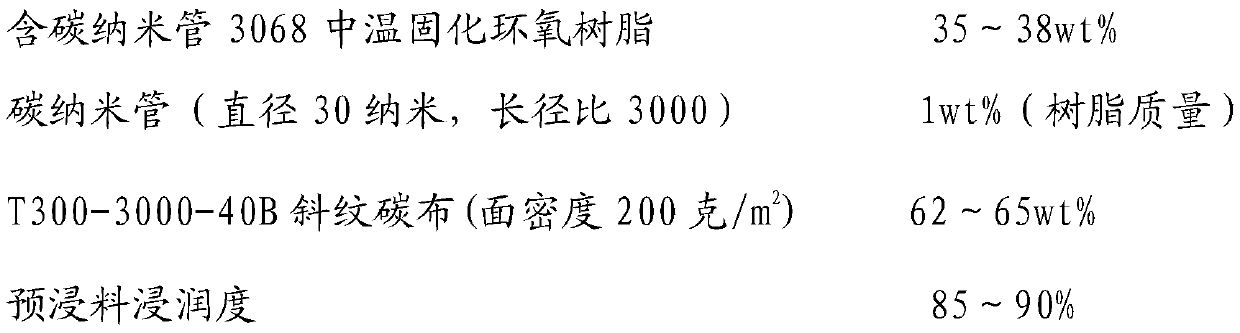

[0058] Prepreg:

[0059]

[0060] Adopt this example prepreg to prepare PMI foam sandwich structure composite material, PMI foam (density 71kg / m 3 ) thickness 2mm.

[0061] The OOA process is adopted as follows:

[0062] 1. Prepare 3068 medium temperature curing epoxy resin for prepreg.

[0063] Weigh a certain amount of carbon nanotubes and 3068 medium-temperature curing epoxy resin, mix them with a mixer until there is no dry powder, pour them into a three-roll mill and grind them for 3-5 times to obtain a carbon nanofiber masterbatch. According to the resin process requirements for prepreg production and the nanofiber content requirements in the resin, add curing agent, accelerator, and nanofiber masterbatch to the reaction kettle in proportion, stir evenly and degas to obtain the resin for prepreg.

[0064] 2. Prepare T300-3000-40B twill carbon cloth / 3068 resin prepreg.

[0065] The carbon nanotube-containing 3068 resin content in the prepreg is 35-38 wt%. When com...

Embodiment 2

[0078] Prepreg:

[0079]

[0080] The preparation process of the foam sandwich structure composite material is the same as that of Example 1, and the flat tensile strength and surface density of the PMI foam sandwich structure composite material are shown in Table 1.

Embodiment 3

[0082] Prepreg:

[0083]

[0084] Aramid paper honeycomb sandwich structure composite material adopts aramid honeycomb density (29kg / m 3 ) thickness 2mm, aramid paper honeycomb sandwich structure composite material preparation process is the same as embodiment 1, and the difference between this embodiment and embodiment 1 is:

[0085] Step 5, the honeycomb sandwich structure composite material is pre-compacted.

[0086] Vacuumize the encapsulated sandwich structure composite material assembly at room temperature for 2 hours to further discharge the gas entrapped in the prepreg and the air in the interlayer of the sandwich structure,

[0087] Step 6, pre-curing.

[0088] Keep warm at 90°C for 4 hours to gradually impregnate the continuous fibers and fabrics in the prepreg with low viscosity, so that the composite panel will be densified. Under the effect, the resin wets and spreads on the surface of the core material to form glue bumps, and the nanofibers in the resin are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com