A kind of heptamolybdate intercalation porous carbon nitride and its preparation method and application

A carbon nitride and acid radical technology, which is applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc. problems, to achieve the effect of simple operation, easy availability of raw materials, and efficient removal of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

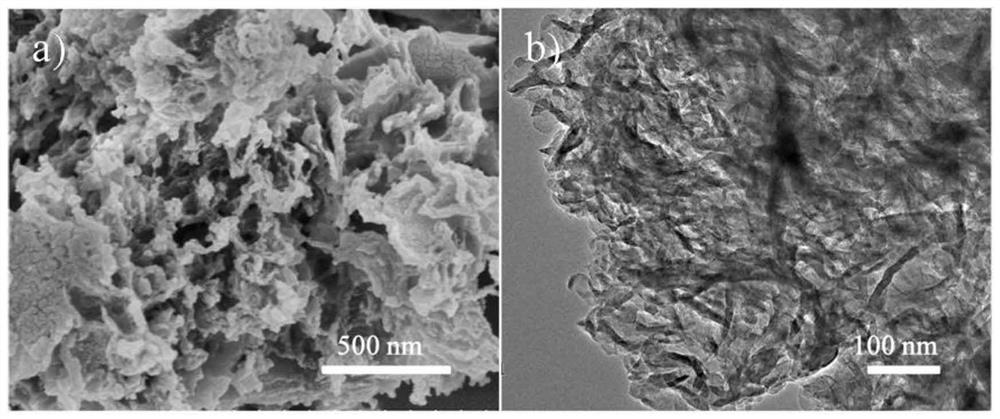

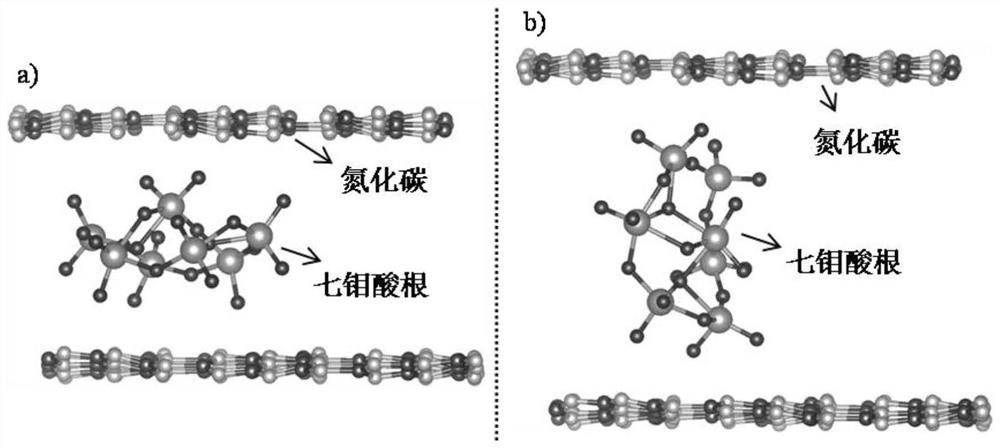

[0032] Preparation of two-dimensional porous layered Mo-UCN, the specific steps are as follows:

[0033] (1) Weigh 5g of dicyandiamide and 1-15g of urea into 40mL of water, place the mixture in a constant temperature water bath at 80°C, and magnetically stir until completely dissolved. Weigh an appropriate amount of ammonium heptamolybdate tetrahydrate (0.015 ~ 0.1g) into the above solution, and continue to stir until the water evaporates completely to obtain a solid mixture;

[0034] (2) After grinding the solid mixture obtained in step (1) into powder, place it in a 50mL ceramic crucible, and continue roasting at 550°C for 3h in a muffle furnace (the heating rate is 2°C / min), naturally Cool to normal temperature to obtain the product catalyst, named as x wt% Mo-UCN-y, wherein x represents the mass ratio (0.3~2) of the preferred ammonium heptamolybdate tetrahydrate and dicyandiamide: 1, and y represents the preferred urea and dicyandiamide The mass ratio of cyanamide (0.2~3)...

Embodiment 2

[0036] Detect the visible light degradation effect of the two-dimensional porous layered Mo-UCN prepared in Example 1 on BPA, the specific operations are as follows:

[0037] (1) Add 50mL of BPA solution (10mg·L -1 ) and 50mg catalyst;

[0038] (2) Under dark conditions, magnetically stir the suspension for 30 minutes to achieve adsorption-desorption equilibrium;

[0039] (3) Then in visible light (wavelength λ>420nm, light intensity 20mw cm -2 ) to catalyze the reaction. Samples were taken at regular intervals, passed through a 0.45 μm filter membrane to obtain clear liquid, and the change of BPA concentration in the solution was determined by high performance liquid chromatography.

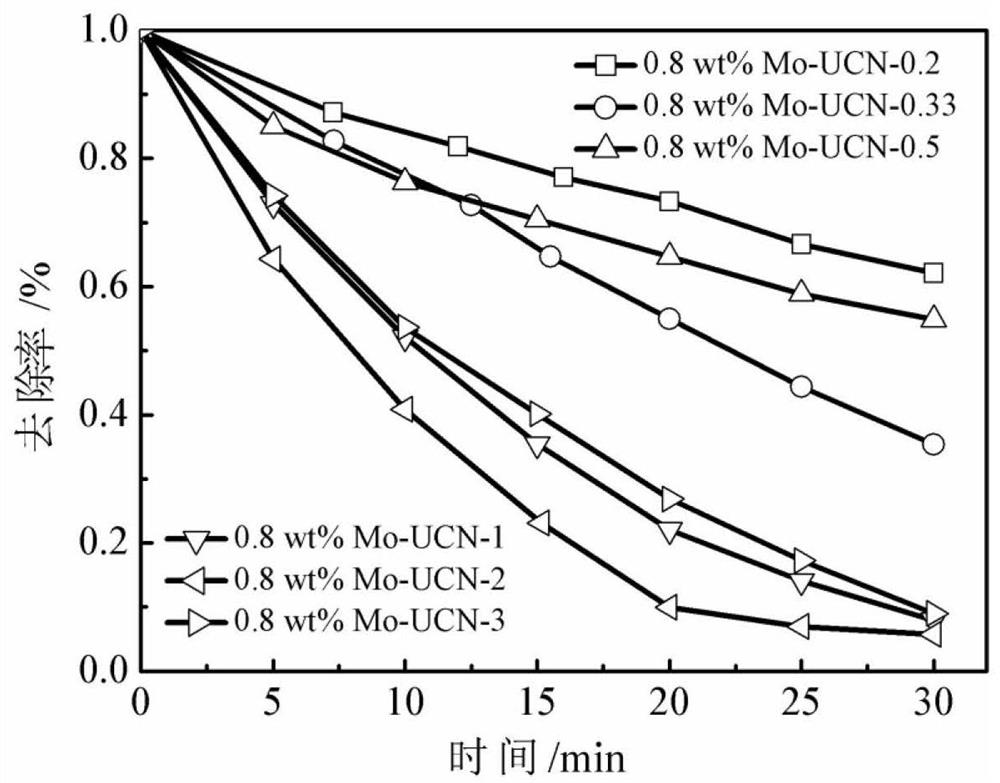

[0040] image 3 0.8wt% Mo-UCN-0.2~3 prepared for different amounts of pore-forming agents on the photodegradation performance spectrum of BPA, Figure 4 The photodegradation performance map of BPA prepared by 0.3-4wt% Mo-UCN-2 for different molybdenum source contents; from image 3 and 4 It...

Embodiment 3

[0042] Detect the stability and recycling effect of the two-dimensional porous layered Mo-UCN prepared in Example 1, and use 0.8wt% Mo-UCN-2 with the best catalytic activity as the target sample for testing. The specific operations are as follows:

[0043] (1) Add 50mg of 0.8wt% Mo-UCN-2 catalyst and 50mL of BPA solution (10mg·L -1 );

[0044] (2) Under dark conditions, magnetically stir the suspension for 30 minutes to achieve adsorption-desorption equilibrium;

[0045] (3) Then in visible light (wavelength λ>420nm, light intensity 20mw cm -2 ) to catalyze the reaction. Samples were taken at regular intervals, passed through a 0.45 μm filter membrane to obtain clear liquid, and the change of BPA concentration in the solution was determined by high performance liquid chromatography.

[0046] (4) After the photocatalytic reaction, the remaining suspension was passed through a 0.45 μm filter membrane, washed and dried to obtain the residual catalyst, and steps (1) to (4) were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com