Two-section lifting self-adaptive flexible picking mechanism

A lifting mechanism and self-adaptive technology, applied in the fields of application, horticulture, botany equipment and methods, etc., can solve the problem that cannot meet the actual harvesting environment and requirements of factory production, identify highly damaged mushrooms, and are only suitable for laboratory environments and other problems, to achieve the effect of compact structure of rotation control, protection from damage, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

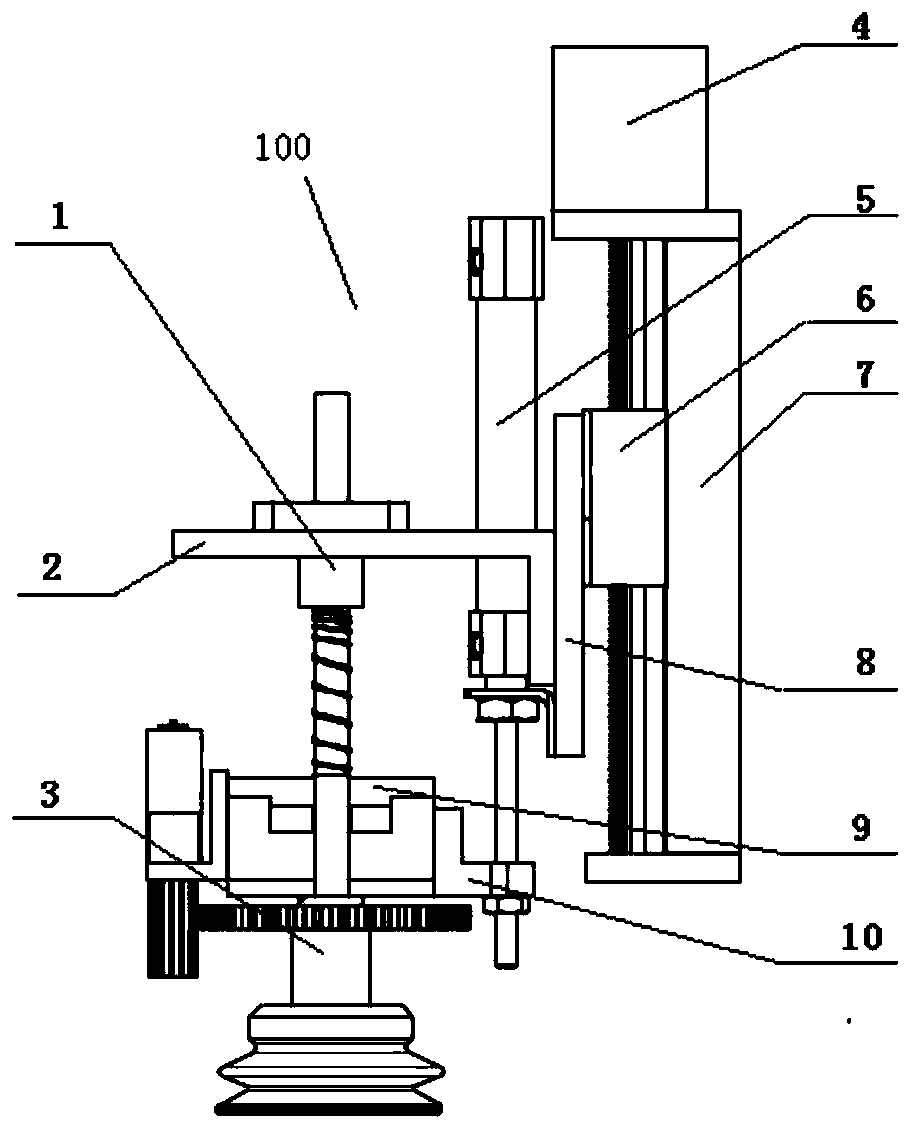

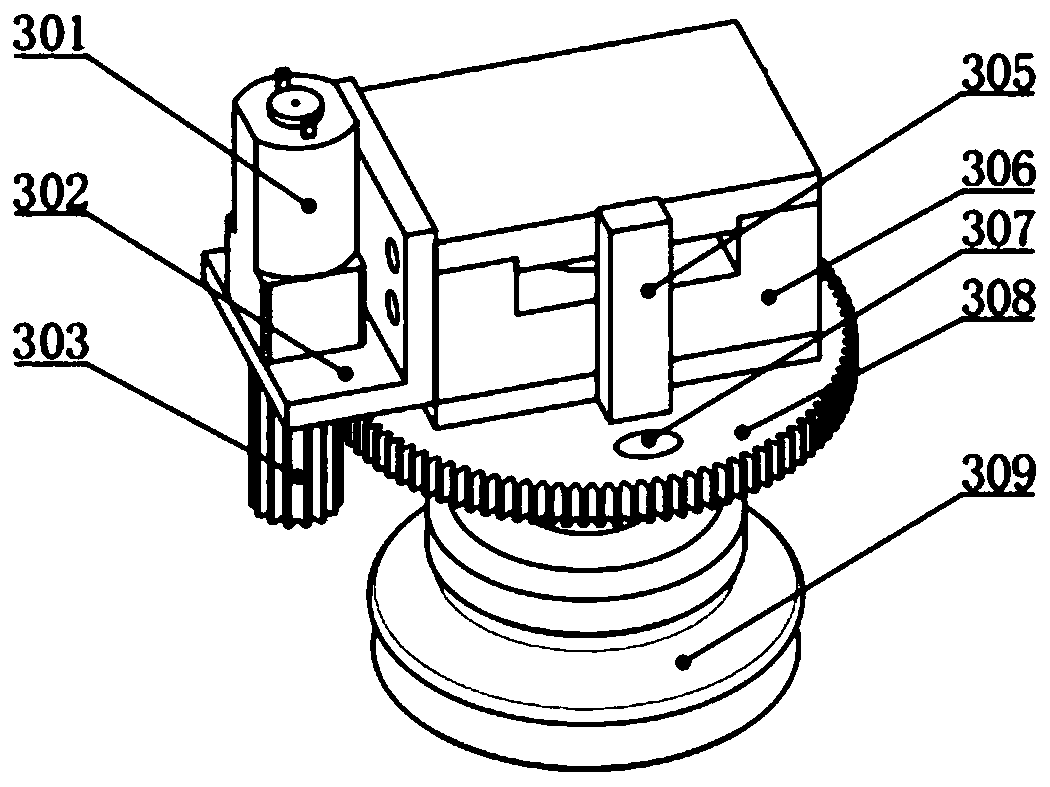

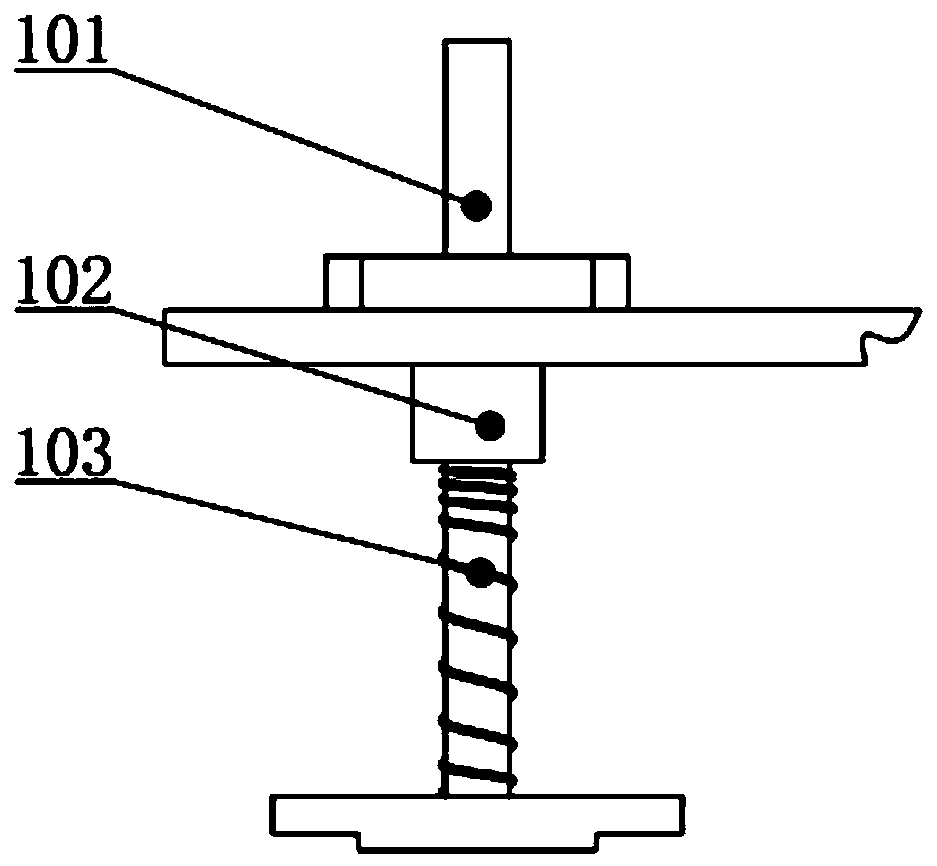

[0042] see Figure 1-5 , The two-stage lifting adaptive flexible picking mechanism 100 of the present invention includes a flexible terminal picking mechanism 3, a sliding sleeve sliding rod lifting mechanism 1 (connected with the cylinder 5), a linear position motion lifting mechanism 7 (controlled by the second motor 4). Wherein, the flexible terminal picking mechanism 3 includes a flexible adsorption cavity 309 and a rotation control mechanism. Wherein the rotation control mechanism includes a first motor (miniature direct current motor) 301, a first gear 303, a second gear (ultra-thin gear) 308, a miniature position sensor 305, and an induction sheet (magnet) 307, wherein the first gear ( 303) adopt the micro-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com