Multifunctional silencer

A muffler, multi-functional technology, applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve hidden dangers, personal safety, high working height, etc., to reduce the direct impact force, reduce maintenance costs, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

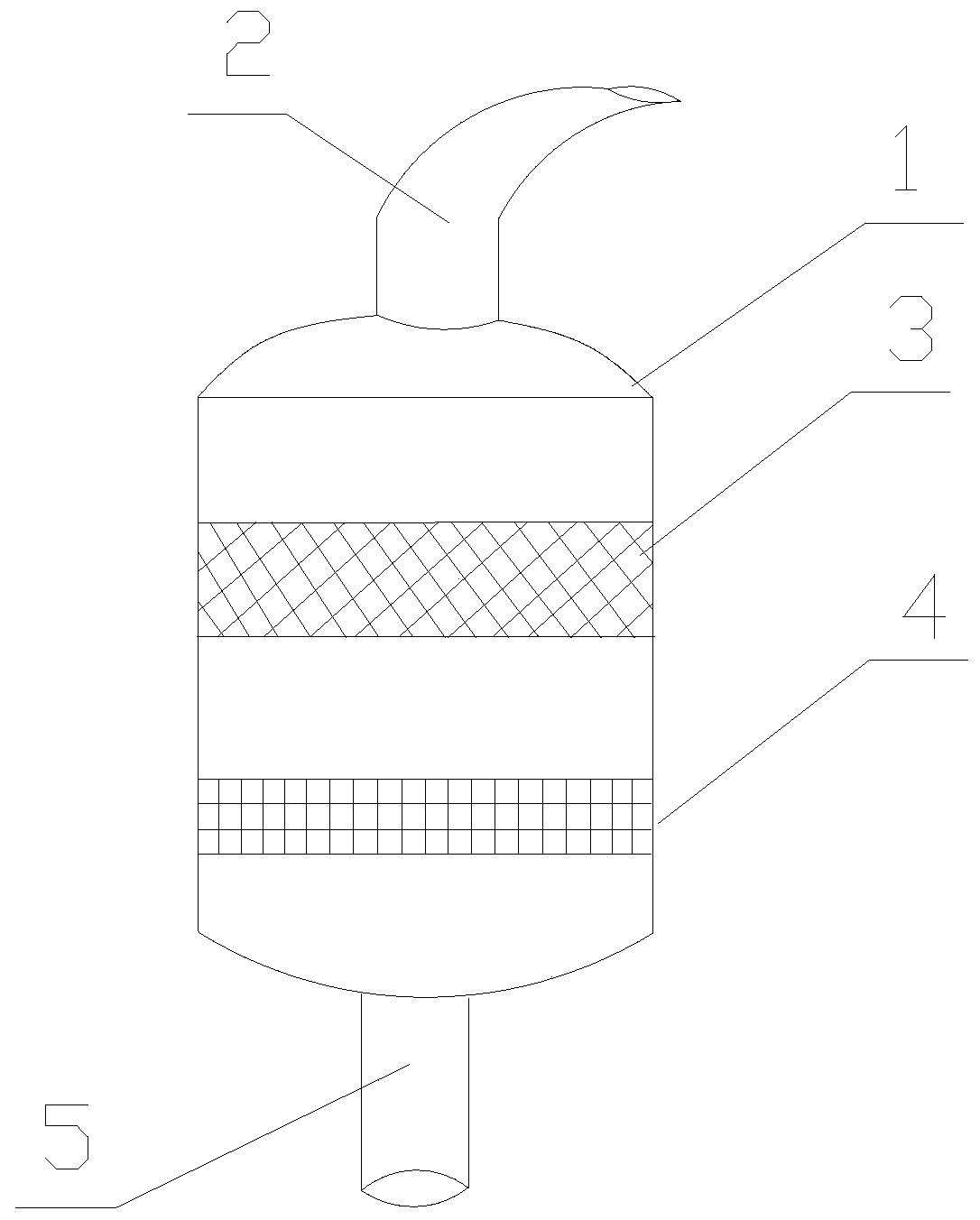

[0020] The following is attached figure 1 The technical scheme of the present invention is described in further detail:

[0021] A multifunctional silencer used to eliminate or reduce the noise generated by the airflow of chemical pipelines, such as figure 1 As shown, it includes a cylinder 1 and a bottom pipe 5, the bottom of the cylinder 1 is connected to the top of the bottom pipe 5, and also includes a discharge pipe 2, the discharge pipe 2 is connected to the top of the cylinder 1, and the middle and lower part of the cylinder 1 is set There is a first sound-absorbing layer 4, and a second sound-absorbing layer 3 is provided on the middle and upper part of the cylinder.

[0022] The upper part of the discharge pipe 2 is arc-shaped, which can reduce the noise to a minimum, and at the same time slow down the direct impact force of the airflow in the pipe on the inner wall of the cylinder body 1 or the discharge pipe, reducing maintenance costs. The opening of the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com