Method for extracting nickel, cobalt and iron from low-grade laterite nickel ore

A laterite nickel ore and low-grade technology, applied in the fields of cobalt, iron, and nickel extraction, to achieve good economic benefits, high product quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

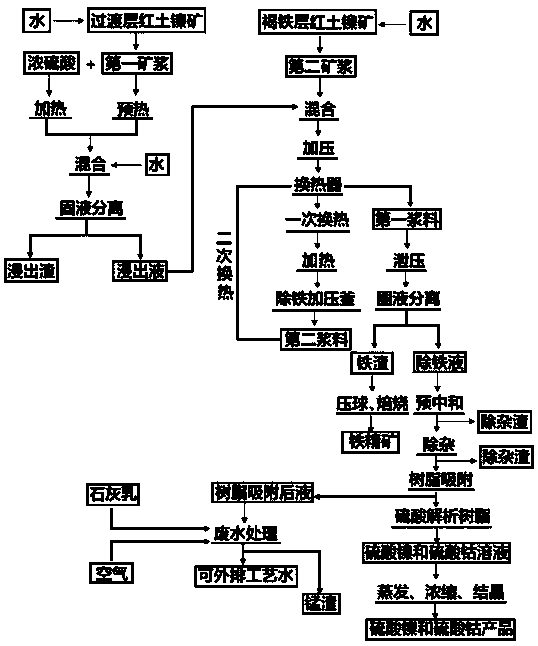

Image

Examples

Embodiment 1

[0026] Take 500kg of lateritic nickel ore in the transition layer of Saibuku and add water to prepare the first pulp with a mass percentage content of 50%. The first pulp is heated to 70°C, 600kg of concentrated sulfuric acid is weighed and heated to 150°C. Sulfuric acid was mixed and leached at normal pressure for 1 hour. After leaching at normal pressure, 1000 kg of water was added for dilution. The dilution and stirring time was 0.5 h. After liquid-solid separation, 1350 L of normal pressure leaching solution and 128 kg of normal pressure leaching residue were obtained.

[0027]Take 1000kg of Sebuku limonite layer laterite nickel ore and add water to prepare the second pulp with a mass percentage of 50%. The temperature of the mixture obtained by mixing the second pulp with 1350L normal pressure leachate is raised from 30°C to 185°C after a heat exchange. ℃, and then heated the mixture to 235℃ with 270℃ high-pressure steam, and kept it warm for 1h; the heated mixture was rea...

Embodiment 2

[0032] Take 500kg of Philippine transition layer laterite nickel ore and add water to prepare the first pulp with a mass percentage of 50%, heat the first pulp to 80°C, weigh 650kg of concentrated sulfuric acid and heat to 130°C, mix the first pulp with concentrated sulfuric acid Afterwards, carry out atmospheric pressure leaching for 50 minutes, add 1000 kg of water to dilute after normal pressure leaching, dilute and stir for 40 minutes, and obtain 1420 L of normal pressure leaching liquid and 163 kg of normal pressure leaching residue after liquid-solid separation.

[0033] Take 1000kg Philippine limonite laterite nickel ore and add water to prepare the second pulp with a mass percentage of 50%. The temperature of the mixture obtained by mixing the second pulp with 1420L normal pressure leachate is raised from 30°C to 190°C after a heat exchange. Then the mixture was heated to 240°C with 270°C high-pressure steam, and kept for 1 hour; the heated mixture was reacted in an aut...

Embodiment 3

[0038] Take 500kg of Indonesian transition layer laterite nickel ore and add water to prepare the first pulp with a mass percentage of 50%, heat the first pulp to 65°C, weigh 625kg of concentrated sulfuric acid and heat to 140°C, mix the first pulp with concentrated sulfuric acid Afterwards, carry out atmospheric pressure leaching for 30 minutes, add 1000 kg of water to dilute after normal pressure leaching, and dilute and stir for 50 minutes, and obtain 1470 L of normal pressure leaching liquid and 140 kg of normal pressure leaching residue after liquid-solid separation.

[0039] Take 1000kg of Indonesian limonite laterite nickel ore and add water to prepare the second pulp with a mass percentage of 50%. The temperature of the mixture obtained by mixing the second pulp with 1470L normal pressure leachate is raised from 30°C to 200°C after a heat exchange. Then the mixture was heated to 250°C with 270°C high-pressure steam, and kept for 1 hour; the heated mixture was reacted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com