Degradable composite material and preparation method thereof

A composite material and a technology for degrading polyester, applied in the field of degradable composite materials and their preparation, can solve the problems of failing to improve the heat resistance of PLA, failing to improve the crystallization rate of PLA, etc., achieving a simple and efficient preparation method, shortening the production cycle, The effect of increasing matrix viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

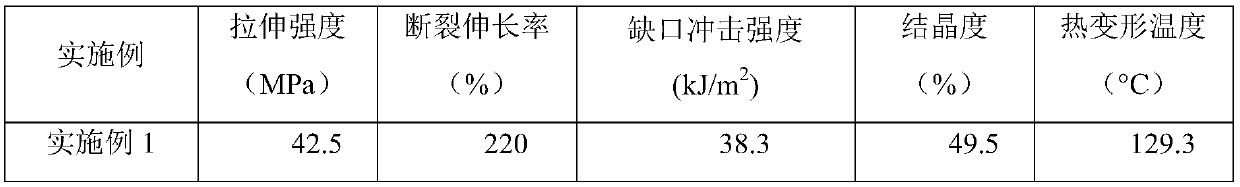

Embodiment 1

[0033]First, 10 parts of PDLA (the number average molecular weight is 90,000, and the optical purity is 98.8%), 20 parts of PBAT (the number average molecular weight is 150,000) and 0.2 part of ADR4370 are added into the internal mixer and carried out melt blending for 5 minutes (blending temperature 200° C.) to obtain a PDLA / PBAT reactive blend (characterized, the reactive blend contains 3 parts of PDLA, 10 parts of PBAT, and 17 parts of PDLA-PBAT copolymer).

[0034] Then 70 parts of PLLA (the number average molecular weight is 130,000, and the optical purity is 99.0%), 30 parts of PDLA / PBAT reactive blend and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Propionic acid] pentaerythritol ester 0.3 parts into the internal mixer for melt blending for 4 minutes (blending temperature is 190 ℃); A degradable composite material can be obtained.

Embodiment 2

[0036] First, 12 parts of PDLA (the number average molecular weight is 120,000, and the optical purity is 97.5%), 20 parts of PCL (the number average molecular weight is 120,000) and 0.4 part of hexamethylene diisocyanate are added to the internal mixer for melt blending for 5 minutes (blending temperature is 205° C.) to obtain a PDLA / PCL reactive blend (characterized, the reactive blend contains 5 parts of PDLA, 9 parts of PCL, and 18 parts of PDLA-PCL copolymer).

[0037] Then 60 parts of PLLA (number average molecular weight is 150,000, optical purity is 98.2%), 40 parts of PDLA / PCL reactive blend, 0.2 part of three [2,4-di-tert-butylphenyl] phosphite and Add 0.2 parts of n-octadecyl alcohol ester of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate into the internal mixer and carry out melt blending for 5 minutes (the blending temperature is 200°C); The blend is hot-pressed at a temperature of 210° C., and then annealed at 90° C. for 2 minutes to obtain a degradable composi...

Embodiment 3

[0039] First, 8 parts of PLLA (the number average molecular weight is 90,000, and the optical purity is 98.8%), 20 parts of PCL (the number average molecular weight is 100,000) and 0.3 part of diphenylmethane diisocyanate are added to the internal mixer for melt blending 6 minutes (blending temperature is 190° C.), to obtain a PLLA / PCL reactive blend (characterized, the reactive blend contains 4 parts of PLLA, 12 parts of PCL, and 12 parts of PLLA-PCL copolymer).

[0040] Then 72 parts of PDLA (number average molecular weight 120,000, optical purity 97.5%), 28 parts of PLLA / PCL reactive blend and N,N'-bis(2,6-diisopropylphenyl)carbon Add 0.3 parts of diimine into the internal mixer and carry out melt blending for 4 minutes (the blending temperature is 190°C); hot press the obtained blend at a temperature of 200°C, and then anneal at 110°C for 3 minutes to obtain a A degradable composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com