Ultrasonic-enhanced method for removing arsenic in waste acid

A technology of ultrasonic wave and dirty acid, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high cost of gypsum slag treatment, high acid and water consumption, and serious waste of resources. Achieve the effects of improving economic and environmental benefits, saving time, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

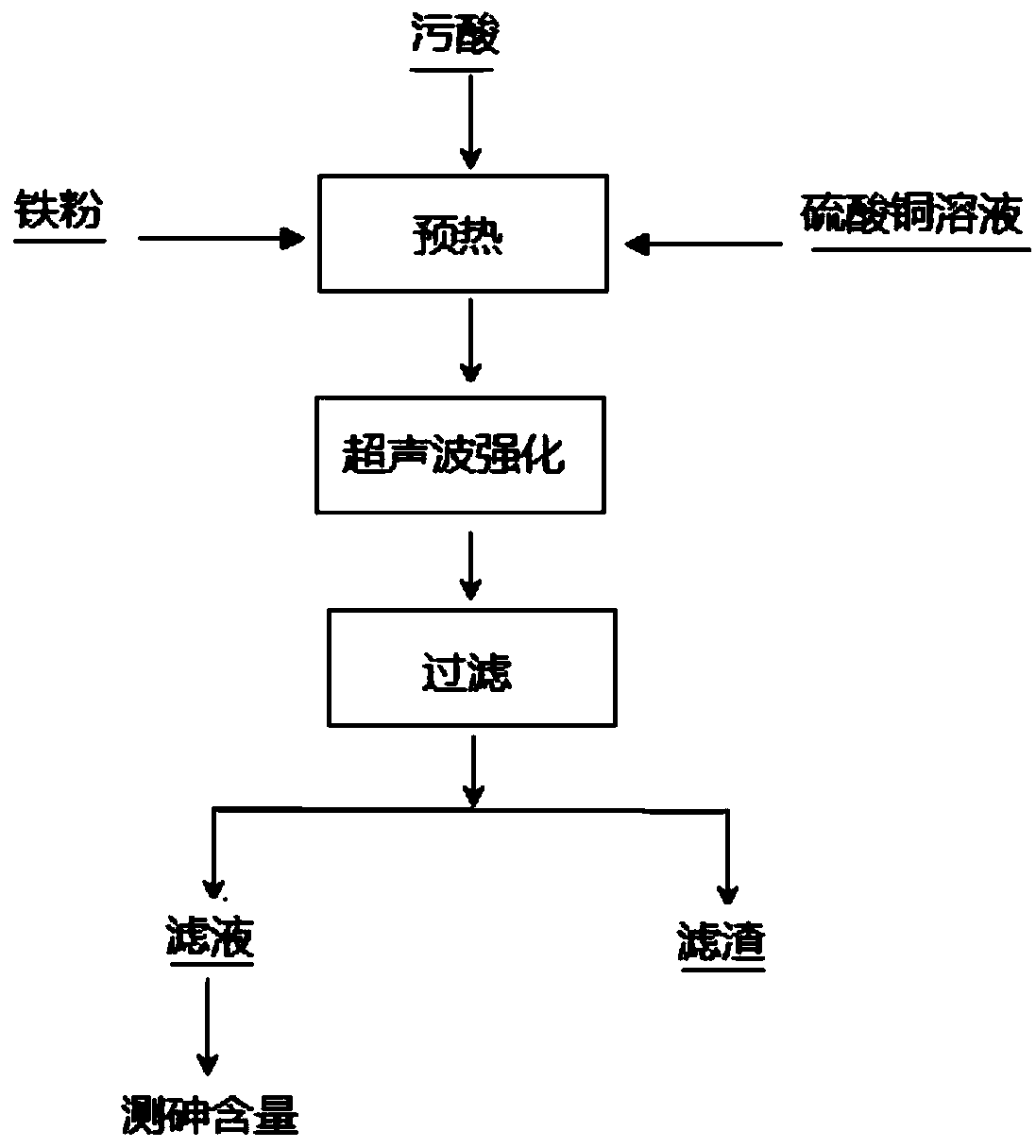

Image

Examples

Embodiment 1

[0128] Take 100mL of dirty acid solution and add it into the reaction kettle and preheat it to 35°C. The dirty acid contains As (as H 3 AsO 3 form) 1050mg / L, Cl (as Cl - form) 1300mg / L, Pb (as Pb 2+ form) 116mg / L, Cd (as Cd 2+ form) 101.7mg / L, F (in the form of F - form) 456mg / L, pH=1.2;

[0129] At the same time, add 0.43g of iron powder and 14.4mL of 50g / L copper sulfate solution to the dirty acid, and stir;

[0130] Then add ultrasonic waves to strengthen the dirty acid, the ultrasonic power is 100W, the frequency is 20kHz, the temperature of the dirty acid is maintained at 35°C, and the ultrasonic strengthening reaction is completed in 10 minutes to obtain a solid-liquid mixture;

[0131] The above-mentioned solid-liquid mixture is suction-filtered to obtain the filtrate and filter residue, and the content of arsenic in the filtrate is measured, and As (as H 3 AsO 3 Form) 1.47mg / L, in the above reaction process, the removal rate of arsenic is 99.86%.

Embodiment 2

[0133] Take 100mL of dirty acid solution and add it into the reaction kettle and preheat it to 35°C. The dirty acid contains As (as H 3 AsO 3 form) 1580mg / L, Cl (as Cl - form) 1025mg / L, Pb (as Pb 2+ form) 198mg / L, Cd (as Cd 2+ form) 98mg / L, F (in the form of F - form) 502mg / L, pH=1.0;

[0134]At the same time, add 0.648g of iron powder and 21.6mL of 50g / L copper sulfate solution to the dirty acid, and stir;

[0135] Then add ultrasonic waves to strengthen the dirty acid, the ultrasonic power is 100W, the frequency is 20kHz, the temperature of the dirty acid is maintained at 35°C, and the ultrasonic strengthening reaction is completed in 10 minutes to obtain a solid-liquid mixture;

[0136] The above-mentioned solid-liquid mixture is suction-filtered to obtain the filtrate and filter residue, and the content of arsenic in the filtrate is measured, and As (as H 3 AsO 3 form) 2.06mg / L, in the above reaction process, the removal rate of arsenic is 99.870%.

Embodiment 3

[0138] Take 100mL of dirty acid solution and add it into the reaction kettle and preheat it to 35°C. The dirty acid contains As (as H 3 AsO 3 form) 966mg / L, Cl (as Cl - form) 1103mg / L, Pb (as Pb 2+ form) 156mg / L, Cd (as Cd 2+ form) 86.5mg / L, F (in the form of F - form) 598mg / L, pH=1.5;

[0139] At the same time, add 0.396g of iron powder and 13.2mL of 50g / L copper sulfate solution to the dirty acid, and stir;

[0140] Then add ultrasonic waves to strengthen the dirty acid, the ultrasonic power is 100W, the frequency is 20kHz, the temperature of the dirty acid is maintained at 35°C, and the ultrasonic strengthening reaction is completed in 10 minutes to obtain a solid-liquid mixture;

[0141] The above-mentioned solid-liquid mixture is suction-filtered to obtain the filtrate and filter residue, and the content of arsenic in the filtrate is measured, and As (as H 3 AsO 3 Form) 2.46mg / L, in the above reaction process, the removal rate of arsenic is 99.745%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com